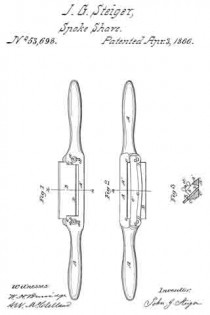

No. 53,698 – Improvement In Spokeshaves (John G. Steiger) (1866)

UNITED STATES PATENT OFFICE.

_________________

JOHN G. STEIGER, OF CLEVELAND, OHIO.

IMPROVEMENT IN SPOKESHAVES.

_________________

Specification forming part of Letters Patent No. 53,698, dated April 3, 1866.

_________________

To all whom it may concern:

Be it known that I, J. G. STEIGER, of Cleveland, in the county of Cuyahoga and State of Ohio, have invented certain new and useful Improvements in a Box-Scraper and Draw-Shave Combined; and I do hereby declare that the following is a full and complete description of the same, reference being had to the accompanying drawings, making a part of this specification, in which —

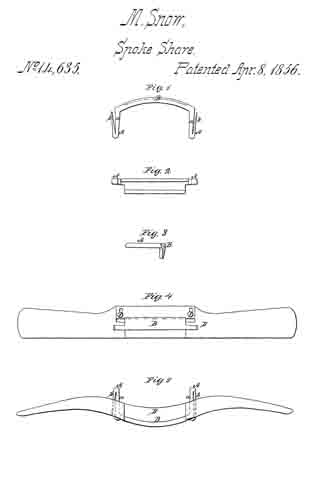

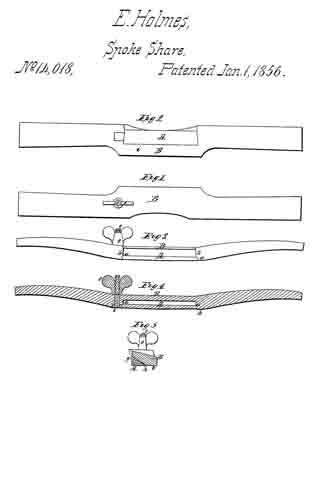

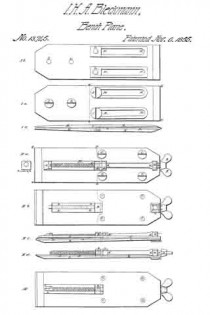

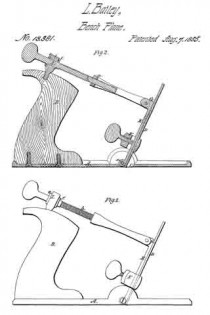

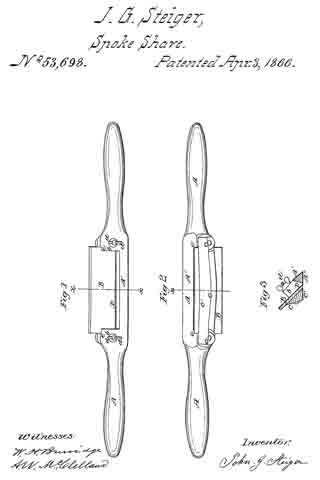

Figure 1 is a top view. Fig. 2 is a view of the under side. Fig. 3 is a transverse section in the direction of the lines x x Figs. 1 and 2.

Like letters of reference refer to like parts in the several views.

My improvement relates to a combined box-scraper and draw-shave, constructed and arranged as hereinafter described.

The draw-shave consists of an elongated metal piece, the ends A of which are shaped into handles, as represented in Figs. 1 and 2. The middle part, A’, is formed into a neck with shoulders b on each side.

B is the blade or scraper, the ends of which it into the shoulders, as shown at e.

C is a clamp fitting onto one side of the blade, holding it in place, being secured or clamped on by means of thumb – screws d, screwed through the shoulders b into the ends of the clamp, which come against one side of the shoulders. The under side, C’, of the clamp and A” of the neck, where the edge of the blade B comes through, are flat and smooth, as seen in Figs. 2 and 3.

The blade B is inclined in its position, as represented in Fig. 3, between which and the neck A’, transversely, and between the shoulders b, longitudinally, the throat D is formed, where the scrapings and shavings pass up through as it is used.

The handles A, neck A’, and shoulders b are east in one entire piece, the clamp C like-wise, so that it is very simple and economical in its construction.

The blade is made of one piece, and can be set in or out more or less, as may be desired, by simply adjusting the set-screws; or a new blade can be put in when one is worn out.

When used for a draw-shave it is of the shape represented in Figs. 1 and 2; but for a box-scraper the handles should be turned up or elevated a little, so that the hands will not come in contact with the board as it is drawn over it.

What I claim as my improvement, and desire to secure by Letters Patent, is —

The special construction of the cast handle and clamp,with the shoulders b, formed between the clamp and handle, blade B, and set-screws d, and operating substantially as described.

JOH. G. STEIGER.

Witnesses:

W. H. BURRIDGE,

FRANK ALDEN.