No. 144,823 – Improvement In Metallic Planes (Joseph F. Baldwin) (1873)

UNITED STATES PATENT OFFICE.

_________________

JOSEPH F. BALDWIN, OF BOSTON, ASSIGNOR TO JOHN SULLY, TRUSTEE, OF DEDHAM, MASSACHUSETTS.

IMPROVEMENT IN METALLIC PLANES.

_________________

Specification forming part of Letters Patent No. 144,823, dated November 25, 1873; application filed June 7, 1873.

_________________

To all whom it may concern:

Be it known that I, JOSEPH F. BALDWIN, of Boston, in the county of Suffolk and State of Massachusetts, have invented certain Improvements in Metallic Planes, of which the following is a specification:

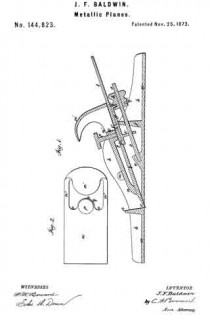

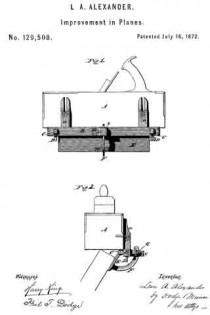

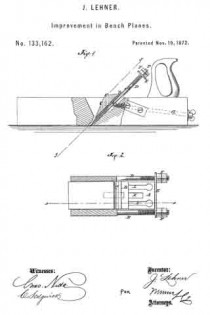

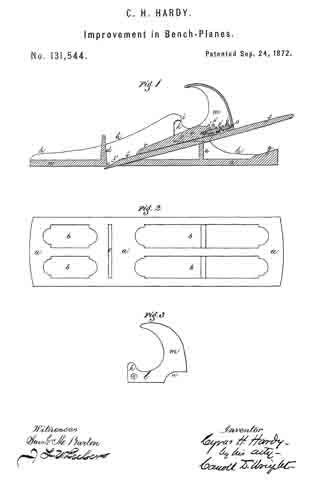

Figure 1 of the accompanying drawings is a central vertical longitudinal section of my improved bench-plane. Fig. 2 is a top view of the plane-wedge.

The present invention relates to certain new and useful improvements in bench-planes, particularly applicable to metallic planes, and having for their principal objects the providing of a simple and convenient means of regulating, so as to vary, the cut of the plan-iron. My improvements consist, mainly, in a metallic or other suitable carriage, arranged and operated, as will be hereinafter more fully described, to travel on an inclined screw-rod, and raise or lower the plane-iron so as to vary its cut, as desired.

In the drawings, a represents the bottom, and b the sides, of the plane. c is the mouth, forward of which is an upright transverse plate or finger -bar, d. The bottom a has formed on, or attached to, the top in the center a boss, e, that tapers upward to receive and hold one end of an inclined rod, s, which extends upward through a transverse vertical plate, f connecting the two sides b at the rear of the center of the plane, and notched on the top at the center to allow of the forward and back inclined travel of a metallic or other suitable carriage, g, formed at the top end with a downward-extending flange, g’, bifurcated at the end to straddle a screw-nut, h, formed with a groove, g”, to receive and hold the flanged end g’, and having female screw-threads that mesh with male screw-threads formed on the upper portion of the inclined rod s, which receives on its smooth or lower portion, so as to allow the travel of a flange, i, that depends from the under side of the lower or forward portion of the carriage, g, which is provided on the top near the lower end with an upward-extending stem, k, that fits into an aperture, l’, formed in the iron, l, which may, if desired, be supplied with one or more supplementary apertures, l”, to allow of the wear of the iron, which may thus be placed either higher or lower on the carriage g. The sides b are formed with, or have attached to them, at a suitable distance above, and at the rear of the mouth, lugs m, between the bottom of which and the top of the iron l is inserted the lower portion of a metallic or other suitable wedge, n, the bottom of which is countersunk, and at the upper portion is made open, as shown in Fig. 2, leaving its sides n” to project rearward and upward to form a curved shield, n’. The top edge of the wedge proper is curved, as shown at o, Fig. 2, and formed in the center with a screw-socket, q, that receives a thumb-screw, p, that is operated against the top of the iron l, so as to raise the upper end of the wedge n, which, acting as a lever, with the lugs m as a fulcrum, causes the bottom of the wedge to bear firmly on the top of the lower end of the iron l, which is thus securely held in position; or, by loosening the screw p the iron l is released, so as to allow of its being raised or lowered to suit the desired cut, or to be withdrawn for sharpening or replacement, &c.

It will readily be seen by the above description, reference being had to the accompanying drawings, that the screw-nut h, turning on the screw-end of the rod s, carries the carriage g, connected with the rod s and nut h by the flanges g’ i, up and down, thus raising or lowering, according to the direction in which the nut is turned, the iron l, which is connected by the stem k with the carriage, by whose operation it is thus readily adjusted to the desired cut.

In a large plane the extended sides n” and the shield portion of the wedge are dispensed with, and the curved top portion of the wedge is extended and formed in the shape shown in Fig. 4, with a central screw-socket, q, for the reception of a screw, p.

Having thus fully described my improvements, what I claim as my invention, and desire to have secured to me by Letters Patent, is —

The carriage g, provided with the flanges g’ i and stem k, in combination with the plane-iron l having orifices l’ l”, the nut h having the groove g”, and the screw-rod s, all arranged and operating substantially as described.

In testimony whereof I have hereunto signed my name to this specification in the presence of two subscribing witnesses.

JOSEPH F. BALDWIN.

Witnesses:

SAML. M. BARTON,

CARROLL D. WRIGHT.