No. 399,760 – Bead-Plane (James Franklin Lewallen) (1889)

UNITED STATES PATENT OFFICE.

_________________

JAMES FRANKLIN LEWALLEN, OF WILMORE, KENTUCKY.

BEAD-PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 399,760, dated March 19, 1889.

Application filed June 20, 1888. Serial No. 277,698. (No model.)

_________________

To all whom it may concern:

Be it known that I, JAMES FRANKLIN LEWALLEN, a citizen of the United States, residing at Wilmore, in the county of Jessamine and State of Kentucky, have invented certain new and useful Improvements in Bead-Planes; and I do declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it appertains to make and use the same.

This invention consists in the novel construction and combination of the several parts, as will be hereinafter more particularly described, and specifically pointed out in the claim.

The invention will be fully understood from the following description and claim, when taken in connection with the annexed drawings, in which —

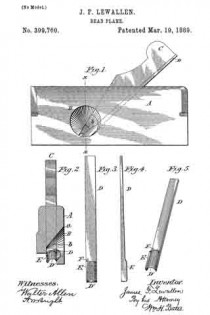

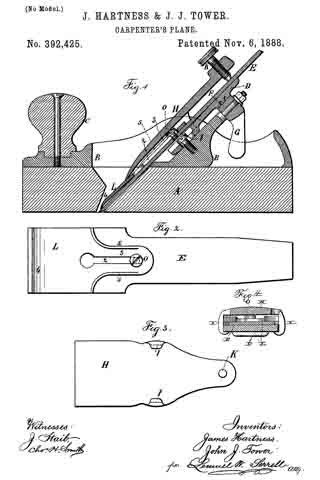

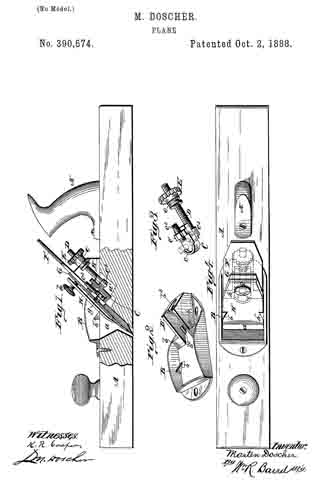

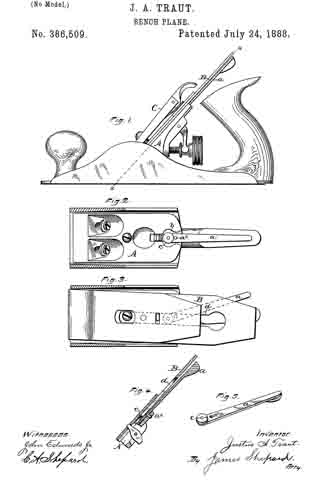

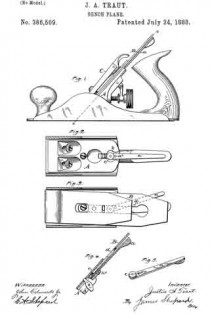

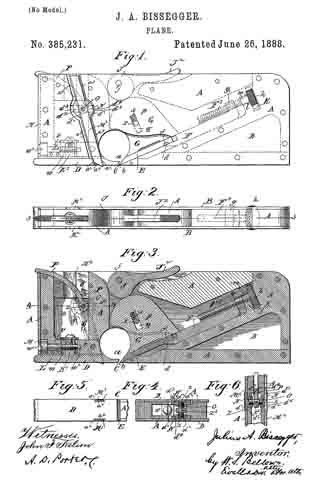

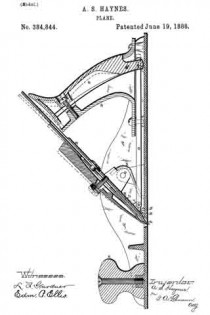

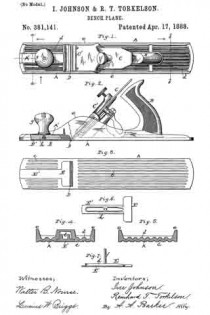

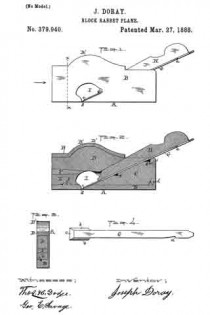

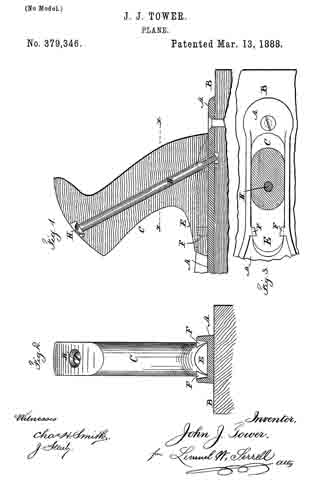

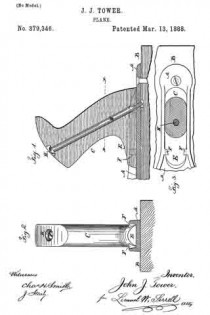

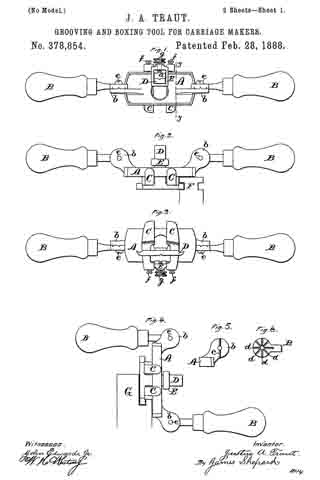

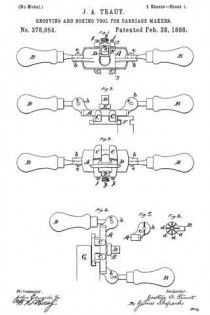

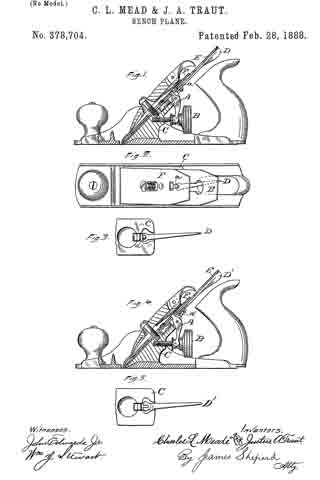

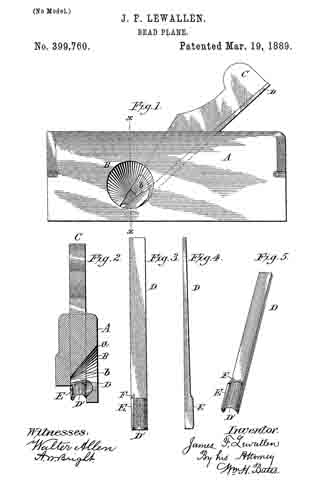

Figure 1 is an elevation of the plane, showing the throat with its bit and key. Fig. 2 is a cross-section on line x x of Fig. 1. Fig. 3 is a plan view of the bit. Fig. 4 is a side elevation thereof; and Fig. 5 is a perspective of the same, showing the flange-cutting lip and the diminishing groove between it and the body of the cutter.

Referring by letter to the said drawings, A indicates a stock, which may be of the form usually employed in bead-planes, having the usual key and bit-seat. At the base of this seat and intersecting the bead is a lateral aperture, B, which is of an annular form and beveled or flaring in its upper portion for the outlet of the shavings, as shown at a.

C indicates the wedge or key for locking the bit in the stock. This wedge, as more fully shown in Fig. 3 of the drawings, is concavely beveled at its lower end-laterally at b, to correspond to the bevel in the lateral aperture B, so as to offer no obstruction to the free discharge of the shavings, and at the same time serve effectively in locking the bit in the stock.

D indicates the bit or cutter, Which is of a peculiar construction, being flat for the greater portion of its length, so as to be snugly seated in the stock. The forward end of this cutter terminates in an edge of substantially ogee form in cross-section, having the semicular upward curvature D’, from one of the longitudinal sides of which rises the upwardly-directed cutting-flange E, divided from the main cutter D’ by a longitudinal groove, F. To this form of cutter I attach importance, as I find in practice that it will cut down into the stock worked upon without tearing up the timber.

By the foregoing construction it will be perceived that the angular part of the cutter will work its way into the wood and form a beading therein to a certain depth before the main part of the bit comes into action. In consequence of this it is essential that the groove be adapted to relieve itself of shavings, for which reason it is made deeper at its cutting-edge than at its terminus in the shank, where it is gradually merged in the flat surface thereof. This arrangement will relieve the groove of the greater quantity of shavings that may be formed therein from the opposing edges of the cutter, and the terminus of the groove when the bit is in the stock will register with the bevel of the key C and facilitate the ejectment of the shavings. By this construction the crimping of the cutting-edge is carried up into the bit-stock, instead of forming merely the outline of the cutting-edge, and the work made by such a bit will have a smoother finish than that ordinarily done.

The throat of the plane with the lower end of the bit-key C forms an oblique cone, the point of its greatest obliquity being toward the month of the plane. This formation insures the ready ejectment of shavings. These pass from the month of the plane into the throat thereof, and, touching against the concavely-beveled end of the key, they pass thence to the surface of the throat, which curls and imparts to them a rotary motion, and finally rapidly ejects them obliquely outward from the stock.

I claim —

In a molding-plane, the combination of the stock having the oblique cone-shaped throat through one cheek thereof, and the bit-key C, having its lower end concavely beveled to conform to the bevel in the throat to form therewith a continuous deflecting discharge-orifice, of a bit having its cutting-edge of substantially ogee form, one side thereof being provided with an upturned cuttingflange, and a groove or depression adjacent thereto, said groove gradually merging in the bit-shank, substantially as described, and for the purpose set forth.

In testimony whereof I affix my signature in presence of two witnesses.

JAMES FRANKLIN LEWALLEN.

Witnesses:

R. T. SHAW,

JAS. W. LOWRY.