No. 1,098,706 – Hand-Scraper (Christian Bodmer) (1914)

UNITED STATES PATENT OFFICE.

_________________

CHRISTIAN BODMER, OF NEW BRITAIN, CONNECTICUT, ASSIGNOR TO THE STANLEY RULE &

LEVEL COMPANY, OF NEW BRITAIN, CONNECTICUT, A CORPORATION OF CONNECTICUT.

HAND-SCRAPER.

_________________

1,098,706. Specification of Letters Patent. Patented June 2, 1914.

Application filed November 8, 1913. Serial No. 799,854.

_________________

To all whom it may concern:

Be it known that I, CHRISTIAN BODMER, a citizen of the United States, residing at New Britain, Hartford county, State of Connecticut, have invented certain new and useful Improvements in Hand-Scrapers, of which the following is a full, clear, and exact description.

My invention relates to an improvement in tools, and particularly to so-called hand scrapers such as employed for scraping or smoothing the surfaces of floors or other woodwork.

The invention relates more particularly to the body portion, which is constructed integrally of cast iron and is so designed as to properly hold the cutter in position for service.

It is the purpose of my invention to provide certain improvements in the construction of the body or frame, and by said improvements to overcome the errors and weaknesses existing in tools of this general description as heretofore constructed; that is to say, by the present design the user may grasp the tool in such a way as to apply his power with the greatest efficiency; the construction also being such that the handle portions are connected to the central body portion by a much stronger connection than that heretofore employed in an iron scraper body or frame.

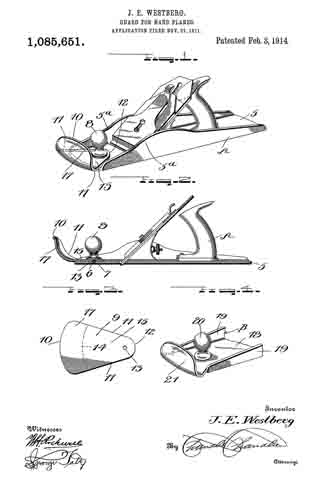

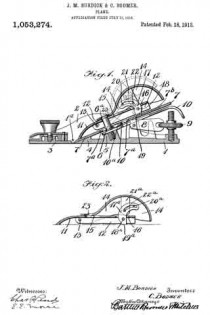

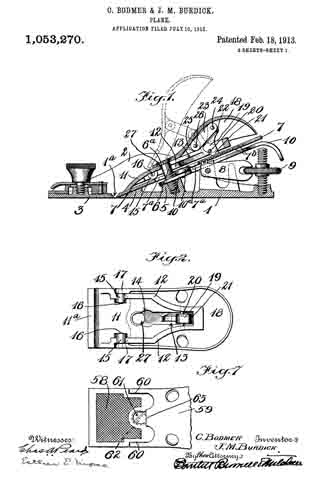

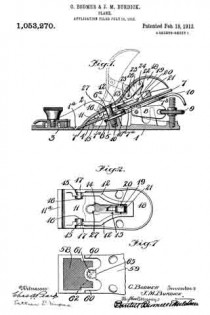

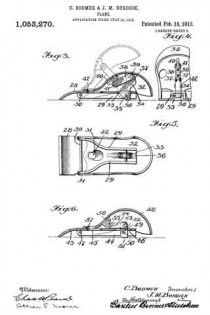

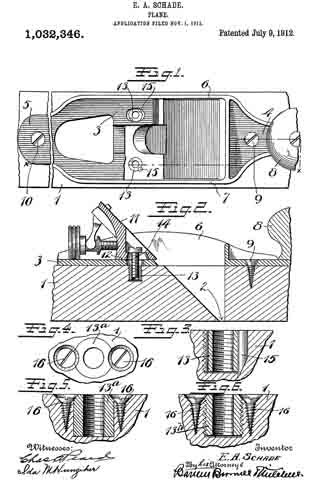

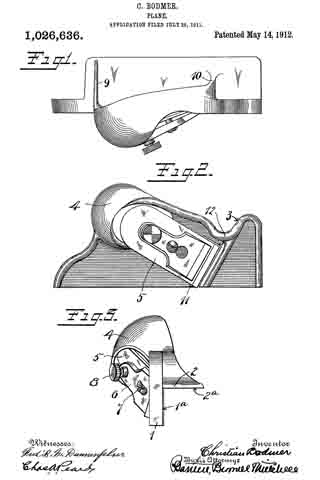

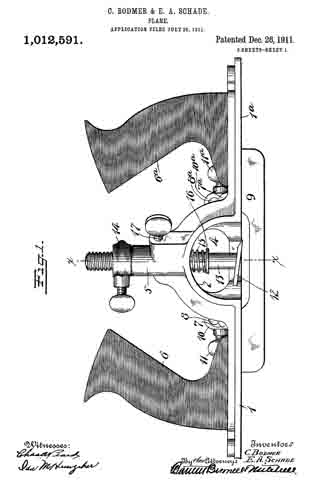

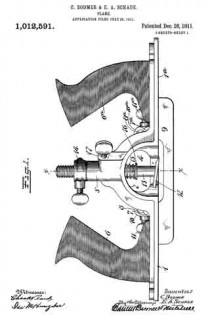

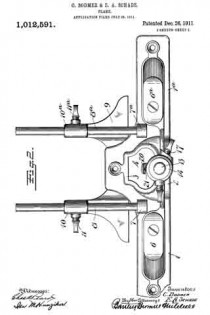

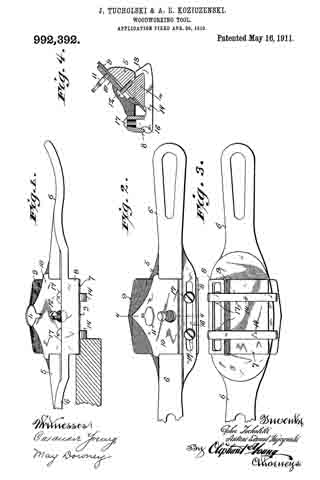

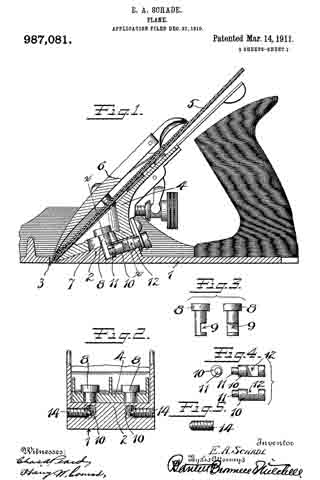

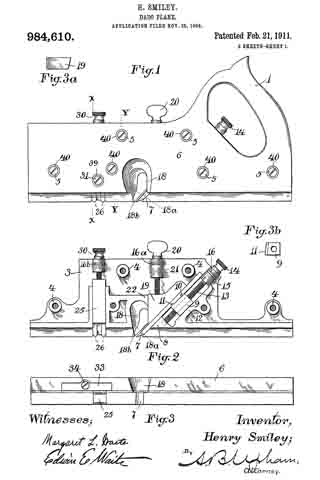

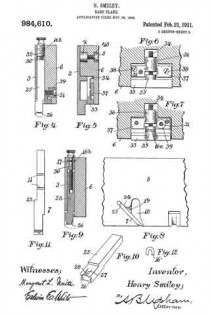

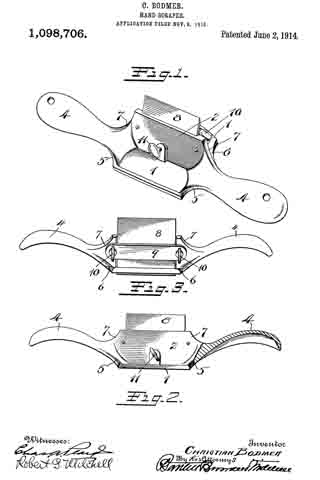

In the accompanying is a perspective view scraper. Fig. 2 is a front elevation, partly in section. Fig. 3 is a rear elevation.

1 is the sole portion or base.

2 is an upwardly projecting wall arranged longitudinally of the base and between the front and rear edges.

3 is a slot which extends transversely through the base about midway betvveen the front and rear edges and just to the rear of the wall 2. The cutter, later described, projects through this slot, the slot being of an appropriate length for the cutter. The sole 1 and the wall 2 constitute the central portion of the scraper body or frame.

4–4 are handles which are arranged at each end of the central or main portion, the handles being cast integrally therewith, each handle being united to the central body portion in the unique manner now described. A description of the means for drawings, Figure 1 of my improved connecting one handle with the main body will suihce for both, as the means of connection corresponds in each instance.

5 is a curved flange connecting the inner end of the handle 4 with the side edge of the sole portion 1 forward of the wall 2.

6 is a curved flange connecting the inner end of the handle with the side edge of the sole portion 1 back of the wall 2.

7 is an upwardly curved flange connecting the handle with the side edge of the wall 2. These flanges operate in effect as longitudinally arranged strengthening ribs which extend far enough into the handle portion to constitute a very powerful connection. Each handle proper is in effect corrugated so as to get the maximum strength with the least weight, the corrugation being on the under side and appearing in Fig. 2 at the right hand side.

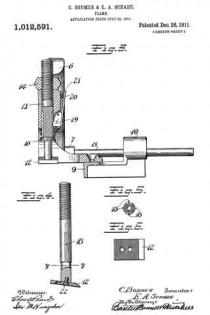

8 is a cutter blade.

9 is a clamping plate connected in any suitable manner, as by thumb screws 10–10 to the rear of the wall 2. This clamping plate 9 serves to hold the blade 8 firmly against the back of the wall 2, with the edge thereof projecting therethrough to the desired extent.

11 is a thumb screw which is located about midway in the wall 2 on the opposite side from the thumb screws 10–10. The inner end of this thumb screw 11 is arranged to engage the blade 8 to bend it slightly baclr at the center, as it is found that it operates more easily when thus buckled or bent.

In operation, the operator grasps the handles 4–4 with the fingers, while his thumbs project down into the spaces at the meeting angles of the front part of the sole, the front part of the wall and that part of the handle between the flanges 7 and 5. The ball of each thumb rests well down on the upper surface of the sole 1 very close to the work, so that the pressure of the thumbs will be applied to the greatest advantage, the position of the thumbs being such that a minimum of exertion is required of the operator, each thumb standing in a substantially straight position rather than being bent. Heretofore in the construction of iron scraper bodies it has been customary to provide a substantially vertical wall at each end of the sole 1, forming a box-like structure, thus requiring the operator to bend each thumb in order to get any thumb pressure directly on the sole. This is not only tiresome, but it is obvious that the operator’s full power cannot be applied when the pressure is exerted through the end of the thumb. It is apparent, of course that each handle curves upwardly so as to afford clearance for the fingers. In this, however, there is no novelty, as it is common in all scrapers of this general class.

In the old box-like type of construction above referred to, the connection between the handles and the main central body is comparatively weak, with the result that if the tool is accidentally dropped, breakage frequently occurs where one or the other handle is united to the main body. By the present invention I not only avoid the box-like structure due to the old end wall formation, but I also connect each handle with the main central body so that a maximum of strength is afforded, very much minimizing the danger of breakage. I have referred to that part of the main body which faces the operator as the front part. It will be understood that in operating the scraper the cutting stroke is performed ordinarily by pushing the tool away from the operator while pressing it firmly against the surface which is to be smoothed.

What I claim is:

1. A scraper body including a main central portion comprising a sole having a slot therein constituting a cutter opening, a wall projecting upwardly at the forward edge of said cutter opening, two handles arranged at opposite ends of the main central portion and integrally connected therewith, said connection including a series of longitudinally arranged rib-like flanges extending from the edges of the sole portion and said wall and merging by gentle curves into and forming part of the handles.

2. A scraper body including a main central portion comprising a sole having a slot therein constituting a cutter opening, a wall projecting upwardly at the forward edge of said cutter opening, two handles arranged at opposite ends of the main central portion and integrally connected therewith, said connection including a series of longitudinally arranged rib-like flanges extending from the edges of the sole portion and said wall and merging by gentle curves into and forming part of the handles, each handle being connected to the cutter opening by not less than three of said rib-like flanges, one of said flanges extending forwardly to meet the side edge of the sole forward of the wall, another extending rearwardly to meet the edge of the sole to the rear of the wall, another extending upwardly to meet the edge of said wall.

3. A scraper body including a main central portion comprising a sole having a slot therein constituting a cutter opening, a wall projecting upwardly at the forward edge of said cutter opening, two handles arranged at opposite ends of the main central portion and integrally connected therewith, said connection including a series of rib-like flanges extending longitudinally from the edges of the sole portion and said wall and merging by gentle curves into and forming part of the handles, with means for holding a cutter against the rear surface of said wall.

CHRISTIAN BODMER.

Wlitnesses :

JNO. BURDICK,

K. J. HOFFDIAN.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________