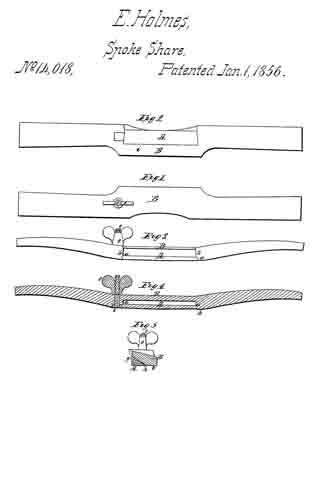

| PLEASE NOTE: The images presented on this page are of low resolution and, as a result, will not print out very well. If you wish to have higher resolution files then you may purchase them for only $2.95 per patent by using the "Buy Now" button below. All purchases are via PayPal. These files have all been cleaned up and digitally enhanced and are therefore suitable for printing, publication or framing. Each zip package contains all the images below (some packages may contain more), and purchased files can be downloaded immediately. |

UNITED STATES PATENT OFFICE.

_________________

ELIJAH HOLMES, OF LYNN, MASSACHUSETTS.

SPOKESHAVE.

_________________

Specification of Letters Patent No. 14,018, dated January 1, 1856.

_________________

To all whom it may concern:

Be it known that I, ELIJAH HOLMES, of Lynn, in the county of Essex and State of Massachusetts, have invented an Improvement in Spokeshaves; and I do hereby declare that the same is fully described and represented in the following speciiication and the accompanying drawings, of which —

Figure 1, represents a top view of a spoke shave provided with my improvement. Fig.

2, is a bottom view of it. Fig. 3, a rear elevation, and Fig. 4, a longitudinal and vertical section of it. Fig. 5, is a transverse and vertical section of it.

My invention relates to the method of adjusting the knife or cutter A, with respect to the stock, B, and for this purpose, and in order to fasten the knife in position, I form the two ends of the knife with chamfers as seen at a, a, in Figs. 3 and 4, and I also form the stock with a dovetail socket or sockets as seen at b, b, to receive said chamfers, they being arranged as seen in the drawings. Through one of these sockets and the stock I extend a screw, c, it being made so that its head shall lap over one of the chamfers, a, as seen in Fig. 4. To this screw I apply a clamp nut as seen at e. When the nut is turned up against the stock, it will draw the head of the screw down upon the knife so as to force the knife longitudinally away from the screw and hard into the opposite socket, b, and so as to confine the knife firmly in place by means of the single screw, its nut and the two sockets. In general two screws are employed to confine the knife in place.

The above mode of fastening not only saves the use and cost of one screw, but enables the knife to be used without having the screw attached directly to it. Each end of the knife rests on a shoulder or plane g, h, (see Fig. 5) which is inclined with respect to the guide i, of the stock, B, and so that by running the knife forward toward the guide, the depression or distance of its cutting edge below the bearing surface of said guide may be changed or increased in order to vary the thickness of the shaving cut by the knife. A rearward movement of the knife will decrease the transverse distance of its cutting edge from the said surface. By means of such inclined shoulders, so arranged with respect to the gage or guide, I am enabled to dispense with the usual movable and adjustable mouth piece and its adjustments commonly applied to spoke shaves.

I do not claim the manner of fastening the knife, viz, by a single-screw clamp, chamfers and sockets as described, but what I do claim is —

Supporting the ends of the knife on planes or shoulders inclined or arranged with respect to the bearing surface of the stock substantially in manner as specified, and so as to enable the distance of the cutting edge of the knife from the said bearing surface to be changed in the way and for the purpose as explained.

In testimony whereof I have hereunto set my signature this sixteenth day of October A. D. 1855.

ELIJAH HOLMES.

Witnesses:

R. H. EDDY,

F. P. HALE, Jr.