| PLEASE NOTE: The images presented on this page are of low resolution and, as a result, will not print out very well. If you wish to have higher resolution files then you may purchase them for only $2.95 per patent by using the "Buy Now" button below. All purchases are via PayPal. These files have all been cleaned up and digitally enhanced and are therefore suitable for printing, publication or framing. Each zip package contains all the images below (some packages may contain more), and purchased files can be downloaded immediately. |

UNITED STATES PATENT OFFICE.

_________________

CHARLES G. MILLER, OF NEW BRITAIN, CONNECTICUT, ASSIGNOR TO OLIVER S. JUDD AND CHARLES BLAKESLEE, OF SAME PLACE.

IMPROVEMENT IN MATCH-PLANES.

_________________

Specification forming part of Letters Patent No. 13,957, dated December 18, 1855.

_________________

To all whom it may concern:

Be it known that I, CHARLES G. MILLER, of New Britain, in the county of Hartford and State of Connecticut, have invented a Combined Tonguing and Grooving Plane, of which the following is a specification, reference being had to the accompanying drawings, in which —

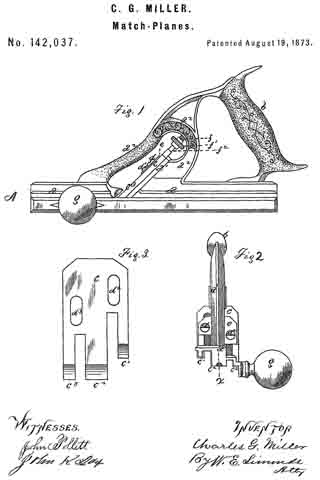

Figure 1 is a side view of the implement. Fig. 2 is an end view of the forward end of the same — the end A. Fig. 3 is a flat view of the under side of the iron.

The plane or tool to which this invention appertains is made of cast metal ; and the invention consists in making an arch to span the cross-cut in which the plane-iron lies, so as to support both ends of the tool, which arch, at the same time, forms a part of the handle of the plane, and forms a back or buttress for the adjusting-screw which controls the adjustment of the plane-iron, this arch being so set on the tool that it can be cast with it all in one piece.

The tool, as shown in the drawings, is made of cast metal, though it may be, with obvious modifications, made of wood or other suitable material. The letter a, indicates the body of the tool, and b the handle, which is hollow, being cored out in casting, from the lower end. That part of the tool to the left of the dotted line x in Fig. 2 does the grooving, and the part to the right of this dotted line does the tonguing, the two parts being so united that either part can be used separately without interfering with the other part. The letter c indicates the chisel or “iron,” so called, which does the cutting. It has three cutting-prongs, c1, c2, and c3. The cutting-prong c1 is the grooving-iron, and c2 and c3 are the tonguing-irons. The whole iron lies upon the oblique ledge or bed a1, and is secured thereto by the headed screws d d1l, running through the cap-plate e, and through the slots d2 d3 into the bed a1. The slots d2 d3 allow the iron to he set and adjusted. An arch, a2, springing from the body of the tool, goes over the top of the iron. Into the under side of this arch is fixed the small screw-bar f upon which is the thumb-nut f1, having a projection, f2, upon one side, bearing upon the top or upper end of the iron c. By means of this thumb-nut the iron can be nicely adjusted downward, when the screws d d1 are slightly loosened. It is screwed down upon the upper end of the iron when it has been adjusted, and thus acts as a support to keep the iron from slipping back: when the tool is hard pressed upon. The letter g indicates the handle for the left hand of the operator.

The adjusting and supporting thumb-nut is applicable to all plane-irons.

From the foregoing description, it will be seen that the arch a2 spans the cross-cut or opening in which the plane-iron lies; that this cross-cut or opening must be open on one side of the tool, to admit of the whole being cast in one piece; that, since this cross-cut is thus open on one side of the arch, it is necessary to support the two ends of the body of the tool; that this arch also forms a part of the handle of the tool; that it forms a buttress for the adjusting screw or nut f1, and that it is so set on the body af as to admit of the whole being cast in one piece.

I claim as my invention —

The combination of the body a, having the cross-cut for the iron open at one side, and the arch a2, spanning the cross-cut and forming a buttress for the adjusting-screw, and also a part of the handle, all of cast metal, in one piece, substantially as described, and for the purposes set forth.

CHARLES G. MILLER.

Witnesses:

F. M. JEROME,

E. KEMPSHALL.