| PLEASE NOTE: The images presented on this page are of low resolution and, as a result, will not print out very well. If you wish to have higher resolution files then you may purchase them for only $2.95 per patent by using the "Buy Now" button below. All purchases are via PayPal. These files have all been cleaned up and digitally enhanced and are therefore suitable for printing, publication or framing. Each zip package contains all the images below (some packages may contain more), and purchased files can be downloaded immediately. |

UNITED STATES PATENT OFFICE.

_________________

EDWARD F. GORDON, OF CONCORD, NEW HAMPSHIRE, ASSIGNOR TO HIMSELF AND JOHN A. WHITE, OF SAME PLACE.

IMPROVEMENT IN LUBRICATORS.

_________________

Specification forming part of Letters Patent No. 213,104, dated March 11, 1879; application filed January 17, 1878.

_________________

To all whom it may concern:

Be it known that I, EDWARD F. GORDON, of Concord, in the county of Merrimack and State of New Hampshire, have invented a new and Improved Lubricator, of which the following is a specification:

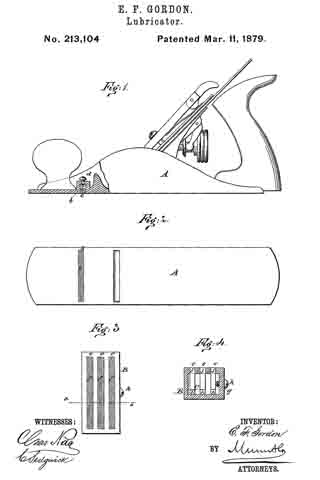

Figure 1 is a side elevation, partly in section, of a plane having my improved lubricating device attached. Fig. 2 is a face view of the same. Fig. 3 is a plan view of a portion of a planer-bed containing my improvement. Fig. 4 is a transverse section taken on line x x in Fig. 3.

My invention relates to lubricators for hand-planes and the beds of planers, molding and scraping machines, or for other metallic surfaces requiring lubrication.

The invention consists in holes or cavities formed in the surface to be lubricated, said cavities being filled with wood or other unyielding porous material saturated with oil. The cavities are either wholly filled with wood or partly filled, so as to leave a chamber for containing oil.

This improvement is especially designed for lubricating metallic surfaces that are moved over wood surfaces, or over which wood surfaces are moved, in the processes of wood-working.

Referring to the drawings, A is an ordinary iron hand smoothing-plane, in the face of which a recess or cavity, b, is formed, into which is driven a piece of wood or other suitable porous material, c, which partly fills it, leaving the chamber c’ for containing oil. The grain of the wood runs at right angles to the face of the plane, so that the capillary tubes of the wood may draw from the oil-chamber a suflicient quantity of oil to constantly lubricate the face of the plane or the surface upon which the plane is moved, thereby obviating the sticking and friction which are common to metallic planes. The upper wall of the oil-chamber is apertured and provided with a screw-plug, d, for the purpose of filling.

In Figs. 3 and 4, B represents a portion of the bed or presser-bar of a planing, sticking, or scraping machine, in which there is an oil-chamber, C. In the upper surface of the bed there are slots e, that communicate with the oil-chamber C. In these slots pieces of wood f are driven, so that the grain is at right angles to the face of the bed, and their upper ends are even with the face of the bed, while their lower ends extend downward and dip into the oil contained by the chamber C. The oil-chamber is provided with a filling-aperture, g, which is closed by a screw-plug, h.

In some cases the oil-saturated wooden plugs or pieces may entirely fill the cavities in the surface to which the lubricator is applied, as the wood will contain a sufficient quantity of oil to lubricate the surface for a considerable time.

I do not limit or confine my improvement to any particular form or proportions, nor to its application to any special tool or machine, as it may he made in various forms, and is applicable to tools and machines of every sort in which wood is moved in contact with a metallic surface, or the metallic surface is moved in contact with the wood, in the processes of wood-working. It may also be applied with advantage to metal-working machines and to metal surfaces working in contact.

I am aware that it is not new to fill recesses in the faces of planers with wood or soap-stone and without any lubricant; also, that it is not new to use a reservoir filled with oil that is fed by a wick or leather conductor; but the latter soon exhausts the oil and soils the stock that is being worked. Mine, on the contrary, always presents a hard, smooth surface, and feeds just a sufficient trace of oil to lubricate without soiling the stock; hence,

What I claim is —

The combination, in wood-working machinery, of the oil-reservoir b and the wooden plug c, the latter having its grain at right angles to the working-face of the planer, scraper, or molder, as shown and described.

EDWARD F. GORDON.

Witnesses:

GEORGE H. MILLS,

CHAS. H. BUXTON.