No. 930,243 – Handle Construction For Planes And Other Tools (Charles B. Stanley) (1909)

| PLEASE NOTE: The images presented on this page are of low resolution and, as a result, will not print out very well. If you wish to have higher resolution files then you may purchase them for only $2.95 per patent by using the "Buy Now" button below. All purchases are via PayPal. These files have all been cleaned up and digitally enhanced and are therefore suitable for printing, publication or framing. Each zip package contains all the images below (some packages may contain more), and purchased files can be downloaded immediately. |

UNITED STATES PATENT OFFICE.

_________________

CHARLES B. STANLEY, OF NEW BRITAIN, CONNECTICUT, ASSIGN OR TO THE STANLEY RULE

& LEVEL COMPANY, OF NEW BRITAIN, CONNECTICUT, A CORPORATION OF CONNECTICUT.

HANDLE CONSTRUCTION FOR PLANES AND OTHER TOOLS.

_________________

930,243. Specification of Letters Patent. Patented Aug. 3, 1909.

Application filed May 8, 1909. Serial No. 494,909.

_________________

To all whom it may concern:

Be it known that I, CHARLES B. STANLEY, a citizen of the United States, residing at New Britain, county of Hartford, State of Comecticut, have invented certain new and useful Improvements in Handle Construction for Planes and other Tools, of which the following is a full, clear, and exact description.

My invention relates to a new and improved tool handle particularly adapted to planes.

The object of the invention is to provide a superior construction by which a strong and durable handle may be formed from composition which would otherwise lack sufficient strength in itself to resist hard usage. Ordinarily this material is molded from some suitalble composition, and it has been found that by reason of the fragile character of most compositions there is great loss due to breakage, not only occurring when the handles are applied to the planes, but also in after use. By my invention the strain of the holding devices is effectively resisted, the molded or pressed composition of the handle being relieved of the same.

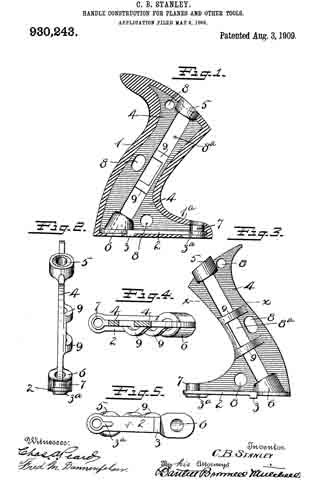

In the accompanying drawings Figure 1 is a vertical section of a plane handle constructed to embody my invention, a portion of the same being shown in side elevation. Fig. 2 is an edge view of reinforcing means detached from the handle. Fig. 3 illustrates the same part and the reverse side from that shown in Fig. 1. Fig. 4 is a section on line x–x of Fig. 3, looking down. Fig. 5 is a view of the under side of the same part.

In the drawings, 1 represents the grip portion of the handle, which may be of conventional form, said grip portion being made of a suitable composition material molded or pressed to the desired configuration. Arranged within the handle is a reinforcement of iron, or other suitable material, capable of withstanding severe strains and hard usage. This reinforcement is preferably of skeleton form and is so arranged as to furnish a backbone for the handle at all vulnerable points, and at the same time is available to receive the screw fastenings (not shown), by which said handles are secured to the plane bodies. This reinforcement comprises the base plate 2, preferably provided with the feet 3–3a, the ends of which feet are coincident with the bottom surface of the finished handle so as to act as a support. The plate 2 has an upwardly extending fin 4, which extends through the grip portion 1 of the handle and well toward the upper end thereof, as best seen in Fig. 1.

5 is an upper bearing for one of the fastening screws (not shown). 6 is a lower bearing for the same screw. The upper bearing 5 is coincident with the upper end of the grip portion of the handle, so that the strain of the screw head when in place will be taken directly by the bearing 5, then by the web 4, then by plate 2, and finally by the bearing 6 and foot 3. 7 is another bearing for another fastening screw, the upper end of this bearing being exposed at the upper surface of a forwardly extending portion 1b at the base of the grip 1. This bearing 7 likewise takes the strain of the head of the second screw, which passes therethrough when the handle is applied.

The web 4, in order to insure lightness may be out away, as at 8–8a, the cut-away portion so being between the bearings 5–6. The two sides of the web adjacent the cut-away portion 8a may have offset connections 9–9 to properly tie together the two parts of the web, said connections being offset to afford clearance passage for the screw. These openings 8–8a permit the composition material to become more rigidly anchored to the reinforcement.

From the foregoing it will be seen that a handle thus constructed possesses very great strength and durability, and the danger of breakage is reduced to a minimum. It will be also seen that the strain of the holding screws is taken wholly by such parts and material as are best capable of withstanding the same. It will also be seen that the composition covering or envelop may be made from a material that would otherwise be unavailable because of too little initial strength, such, for example, as cork. These and other advantages will be apparent to the experienced mechanic.

What I claim is:

1. In a tool handle, a grip of composition material, an interior reinforcement having a screw passage therethrough from end to end of the grip portion of said handle, said reinforcement carrying a bearing at the upper and lower end to receive a fastening screw.

2. In a tool handle, a grip of composition material, an interior reinforcement having a screw passage therethrough from end to end of the grip portion of said handle, said reinforcement having a bearing at each end to receive a fastening screw, and having a second screw passage, and a bearing for a second fastening screw, both of said bearings relieving the composition covering of said reinforcernent from the strain of fastening screws.

3. A tool handle formed of composition material and having an inclosed metallic reinforcement, said reinforcernent having two screw passages therein and having bearings at the base of the reinforcement adjacent to said screw passages, and other bearings at the upper end of both screw passages arranged to directly receive the strain of fastening screws.

CHARLES B. STANLEY.

Witnesses:

ROBERT N. PECK,

W. J. WORAM.