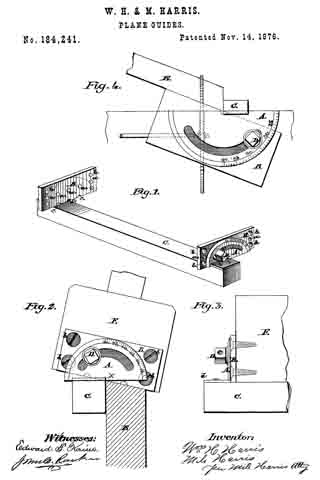

No. 184,241 – Improvement In Plane-Guides (William H. Harris And Milo Harris) (1876)

UNITED STATES PATENT OFFICE.

_________________

WILLIAM H. HARRIS AND MILO HARRIS, OF JAMESTOWN, N. Y.

IMPROVEMENT IN PLANE-GUIDES.

_________________

Specification forming part of Letters Patent No. 184,241, dated November 14, 1876; application filed July 3, 1876.

_________________

To all whom it may concern:

Be it known that we, WM. H. HARRIS and MILO HARRIS, of Jamestown, in the county of Chautauqua and State of New York, have invented certain new and useful Improvements in Plane Guides; and we do hereby declare that the following is a full, clear, and exact description thereof, which will enable others skilled in the art to which it appertains to make and use the same, reference being had to the accompanying drawings, and to the letters of reference marked thereon, which form a part of this specification.

The object of our invention is to furnish a cheap and simple guide for bench-planes, so as to plane or saw any desired bevel; and the nature of the invention consists in the combination of devices employed, as hereinafter more fully set forth.

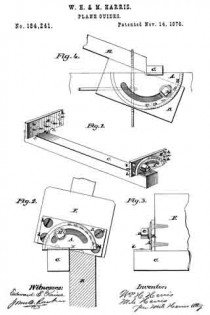

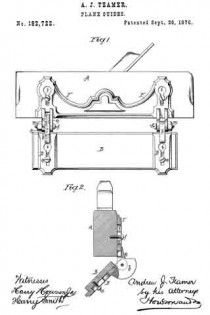

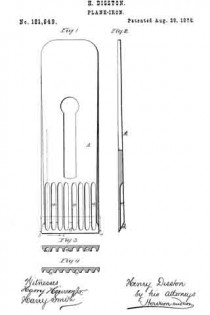

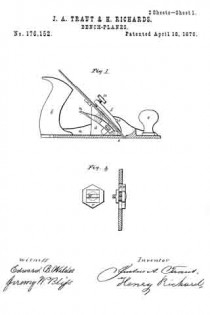

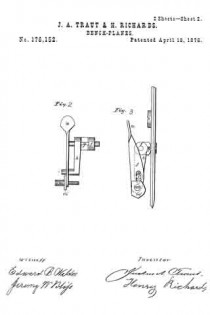

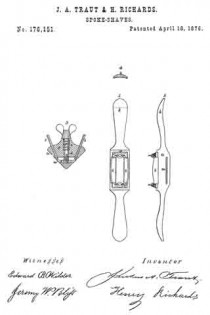

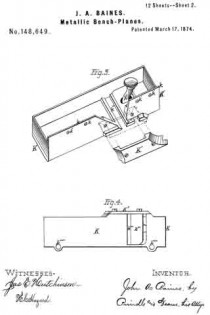

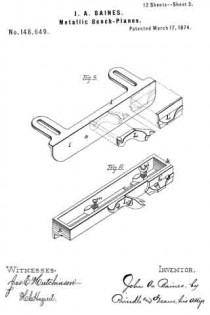

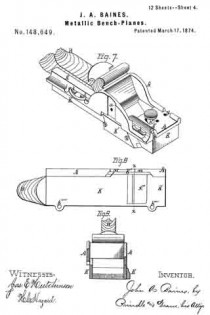

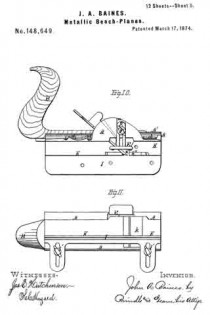

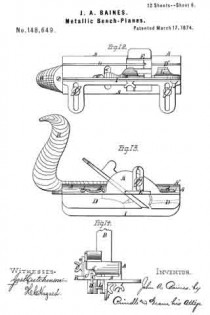

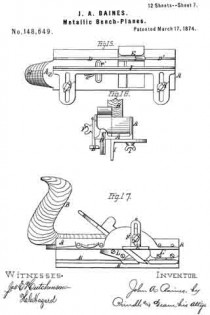

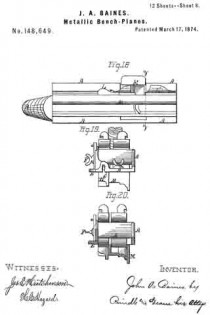

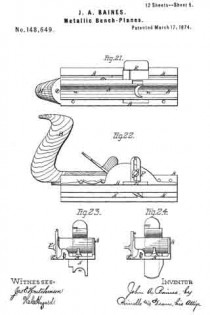

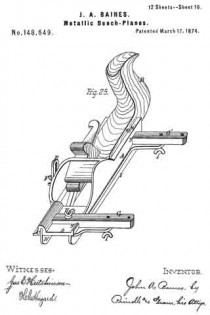

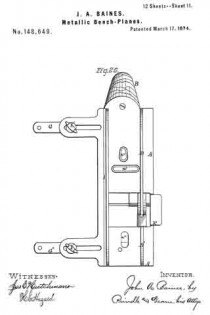

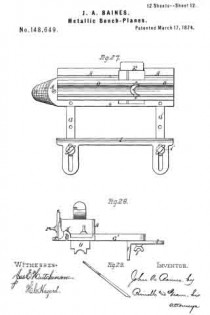

Figure 1 is a view of the guide, with a protractor and end plate attached to each end. Fig. 2 is a view of the metal plate attached to the end of a plane. Fig. 3 is a side view of the plane and guide, with end plate and protractor attached. Fig. 4 is a view of our invention as applied to a saw-table.

ln the drawings, A represents a semicircular bevel-protractor, made of suitable metal, and having a long circular slot near its center, through which the bolt or screw D passes to secure it firmly to the end plate B, and also a semicircular stud, x, at its lower edge, that turns in the semicircular indentures c c c, and also a lip turned at right angles with its surface, through which screws pass to securely fasten it to the guide C. B is a metal plate, that is securely fastened to the end of a plane, as shown in Fig. 2, and having screw-holes for this purpose, and holes a a a, with a screw-thread cut in them to receive the bolt D. It has also sernicircular indentures c c c in its lower edge to receive the stud x of the bevel-protractor. One of these plates, with the bevel-protractor, is fastened at each end of the plane, and, having the guide C attached, is shown in Figs. 1 and 2. The object of having so many places for the bolt D is that by so doing we can use any part of the face of the plane, and by changing ends with the guide C it will work on the back part of the plane-face, thus enabling us to bevel either edge of the board. The object of indentures c c c and stud x is to form a center for the bevel-protractor to turn on, in order that the corner of the guide C will always retain its relative position with the face of the plane, and as the bolt-holes a a a are placed at an angle of forty-five degrees with the indentures c c c we do not have to use but three indentures c c c for all the bolt-holes, no matter on which side of the plane-face the gage is used.

The plate B may be made with a long slot through its center, and a movable nut to receive the bolt D, or said plate may be made dovetailing, and inserted in a movable plate on which the bevel-protractor moves across the plane; but we prefer the manner shown in the drawings, as it is cheaper and more secure.

By means of the semicircular stud x in the bevel protractor A, and the indentures c c c in the metal plate B, the guide C can be moved to any part of the face of the plane, and the inner corner of said guideis held in the exact center of the circle described by the bevel-protractor A, and the guide is kept close to the face of the plane at any angle it maybe turned without any further adjustment, and by turning the lip d parallel with the face of the plane a much thinner guide can be used and thinner lumber planed without coming in contact with the work-bench.

We claim —

The combination of the bevel-protractor A, having stud x and lip d, with the end plate B, provided with the semicircular indentations c c c, the screw-bolt D, and the guide C, all constructed to operate as shown and described, and for the purpose specified.

In testimony that we claim the foregoing as our own invention we affix our signatures in presence of two witnesses.

WM. H. HARRIS.

MILO HARRIS.

Witnesses:

J. E. GOULD,

J. E. HARRIS.