No. 151,188 – Improvement In Crozes (John W. Young) (1874)

UNITED STATES PATENT OFFICE.

_________________

JOHN W. YOUNG, OF WHEELING, WEST VIRGINIA, ASSIGNOR OF ONE-HALF HIS RIGHT TO ANDREW H. BAGGS, OF KIRKWOOD, OHIO.

IMPROVEMENT IN CROZES.

_________________

Specification forming part of Letters Patent No. 151,188, dated May 19, 1874; application filed April 30, 1874.

_________________

To all whom it may concern:

Be it known that I, JOHN W. YOUNG, of Wheeling, in the county of Ohio and State of West Virginia, have invented a new and Improved Croze; and I do hereby declare the following to be a full, clear, and exact description of the same, reference being had to the accompanying drawings forming part of this specification, in which —

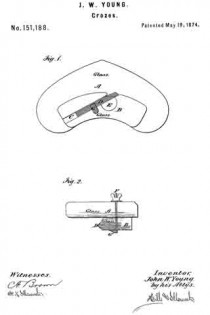

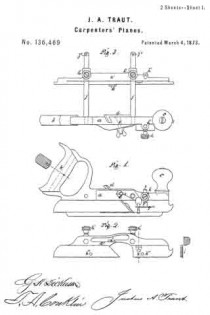

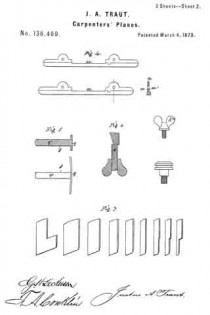

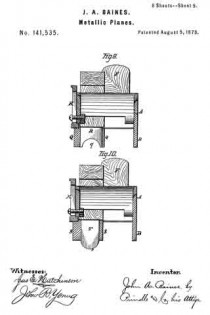

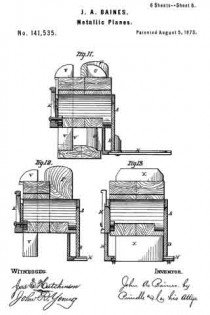

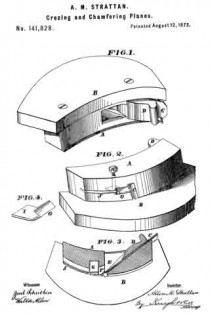

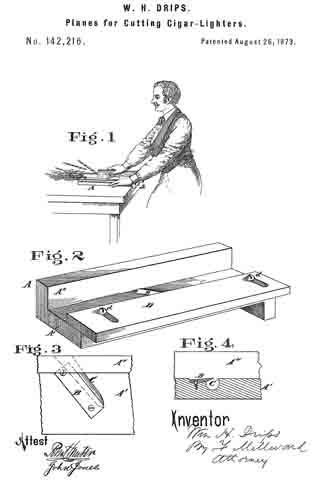

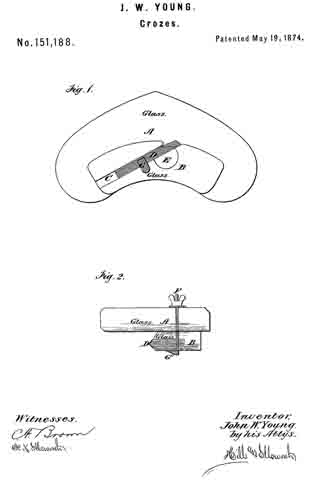

Figure 1 is a bottom-plan view of a cooper’s croze, and Fig. 2 is a side elevation of the same.

Similar letters of reference in the accompanying drawings denote the same parts.

In cooper’s crozes, as ordinarily constructed, the board and guard are made of wood, and in practice it is found that the friction of the edges of the staves upon the board of the croze rapidly wears a groove or gutter in its lower face, which causes the groove made in the staves by such a tool to be situated too low in the barrel, besides causing greater friction in the operation of the croze. The guard also becomes quickly worn in use when made of wood, and it has frequently to be removed from the board and filed or trimmed to restore it to its proper form. The friction of the wooden croze in use is not, also, uniform, thereby causing it to wear more in some places than in others, thereby rendering the tool in a great degree inoperative by cutting a groove in the staves of varying width and thickness.

To remedy these defects, the boards and guards of crozes have heretofore been made of very hard wood, as lignum vitae; but crozes made of that wood are expensive, and have been found to chip, and in time the groove or gutter is formed in the board, and the guard becomes worn, and the objectionable features of the ordinary wooden guard and board are not removed by this change of material.

By constructing the guard and board entirely of glass the objectionable features above described are entirely removed, as no gutter is formed in the board by the staves, and there is no wear of the guard, while the extreme hardness of the glass almost entirely obviates the friction between the croze and barrel, and allows the former to be more easily operated.

By my construction, also, the groove is always made at the proper depth in the barrel, and will be of uniform size throughout.

In the accompanying drawings, A is the board, and B the guard of the croze, made, preferably, in one piece, and constructed in the ordinary manner, with a recess, C, in the guard for the bit D, and an opening, E, in the lower face of the guard for the discharge of chips. F is a bolt passing through an orifice inthe board and guard, and screw-threaded at its end for the reception of a nut, and provided with a projecting lug, G, which bears upon the bottom face of the bit, by means of which construction the bit is securely held in place, and can readily be adjusted in its seat.

The board and guard are preferably made in one piece, the glass forming them being molded and pressed.

By constructing the board and guard of glass, the croze is much more easily operated, and crozes thus constructed can be made with little expense, and obviously they are much more durable than wooden crozes.

Having thus described my invention, what I claim is —

As a new article of manufacture, a cooper’s croze, the board and guard of which are made entirely of glass.

JOHN W. YOUNG.

Witnesses:

NATHAN K. ELLSWORTH,

WM. READ.