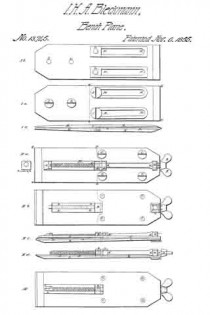

No. 13,745 – Bench Plane Iron (J. Henry A. Bleckmann) (1855)

UNITED STATES PATENT OFFICE.

_________________

J. H. A. BLECKMANN, OF RONSDORF, NEAR ELBERFELD, PRUSSIA.

BENCH-PLANE IRON.

_________________

Specification of Letters Patent No. 13,745, dated November 6, 1855.

_________________

To all whom it may concern:

Be it known that I, J. HENRY A. BLECKMANN, of Ronsdorf, near Elberfeld, in the Kingdom of Prussia, have invented a new and Improved Plane-Iron; and I do hereby declare that the following is a full and exact description thereof.

The nature of my invention consists in forming a plane-iron by placing between iron plates in the shape of the common double plane-irons a steel plate which may be advanced or drawn back by means of screws or a set screw.

The advantages arising from this my invention are, first, that I can employ well tempered steel plates which have not been injured by the process of welding it to another plate as it is done in the manufacture of common single or double plane iron; second, that I can easily change the cutting iron when necessary for another plate of the same temper and cutting quality; third, that it is cheaper than common plane iron now in use.

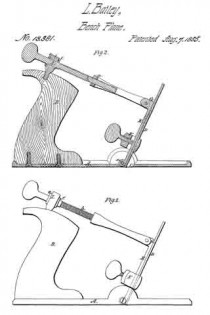

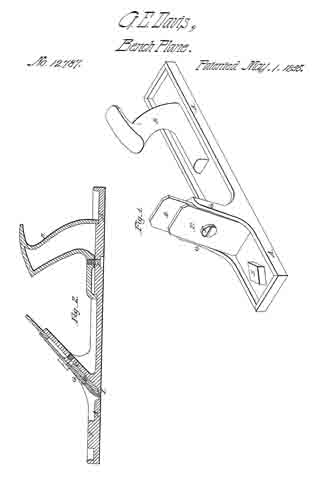

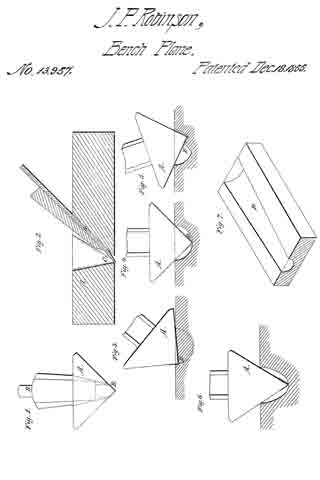

In the annexed drawings, Figure Ia represents a front view of my plane-iron. Fig.

Ib represents a back view of the same. Fig.

Ic represents a side view of the same; Figs.

IIa, IIb, IIc, front, back and side view of a modification; Fig. Id, side view of the same modihcation, taken without the top plate A;

Fig. III another modification.

My improved plane iron consists of two iron plates, A and B, between which a cutting iron, E F G H is placed. In order to keep the cutting iron firm between the front and back plates, I provide them with mortises M M (as seen in Figs. Ia, Ib, Ic) in which I insert screws J J, having nuts L L, by means of which I regulate the cutting iron E F G H. To keep the front and back plates A and B more firm together I provide them with another set of screws C C. When it is required to advance the cutting iron, I unscrew the nuts L L on the back-plate B, and push them and the cutting iron forward as far as necessary, and when the cutting iron has been placed in the desired position, I tighten the screws J J.

Here is another modification of my improved plane iron, (Figs. IIa,IIb, IIc). Instead of regulating the cutting iron by means of mortises and screws as described, I provide the cutting iron with a set screw K, by means of which the cutting iron may be advanced or drawn back at pleasure. For that purpose I construct differently the front and back plates A and B. The front plate A has a mortise M; in this mortise fits a set or regulating screw K, the lower portion of which is provided with a screw thread J J J J ; this regulating screw is kept in place by two pieces L and V, both fastened in the back plate, it works also in a nut R, which fits into the mortise of the cutting iron. The foot of this screw turns and is held in a socket S. When the screw K is turned, the nut R is either carried up or down and consequently the plane iron with it. To give the nut R more steadiness I make it so as to project beyond the mortise of the back-plate B. The back and front plates are kept together by means of four screws C C C C.

To prevent the shavings and dust from entering between the cutting iron E F G H and the top plate A, it is best to make said top plate somewhat curved at the point where it touches the cutting iron.

It is evident that a great many other modifications can be employed to arrive at the same object as I have shown in Fig. III, without departing from the principle of my invention.

What I claim as my invention and desire to secure by Letters Patent is —

The placing of a piece or a plate of steel between plates of iron, forming a plane iron for the purpose and in the manner above described.

J. H. A. BLECKMANN.

Witnesses:

FR. AUG. BUSCHE,

FRIEDR. WILH. ORTMANÜL