No. 23,678 – Bench Plane Stock (Jackson Gorham) (1859)

UNITED STATES PATENT OFFICE.

_________________

JACKSON GORHAM, OF BAIRDSTOWN, GEORGIA.

BENCH-PLANE STOCK.

_________________

Specification of Letters Patent No. 23,678, dated April 19, 1859.

_________________

To all whom it may concern:

Be it known that I, JACKSON GORHAM, of Bairdstown, in the county of Oglethorpe and State of Georgia, have invented a new and useful Improvement in Joiners’ Planes; and I do hereby declare that the following is a full, clear, and exact description of the same, reference being had to the annexed drawings, making a part of this specification, in which —

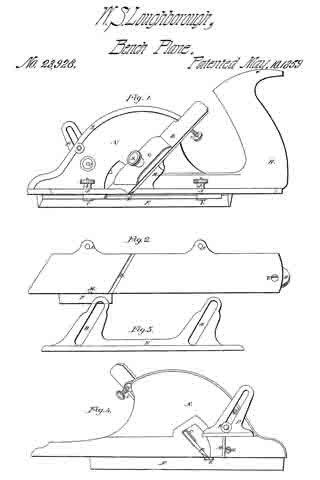

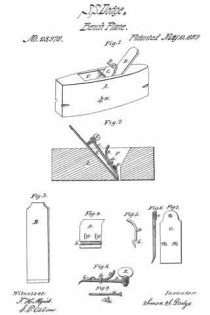

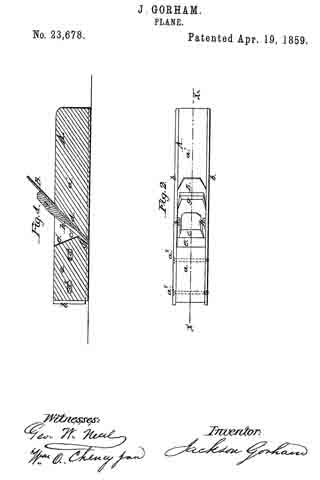

Figure 1, is a longitudinal vertical section of my invention taken in the line x, x, Fig. 2. Fig. 2, is a plan or top view of ditto.

Similar letters of reference indicate corresponding parts in the two figures.

This invention consists in having the stock of the plane formed of wood with metal sides and the front part of the wooden portion made adjustable by means of set screws, so that the “throat” may be enlarged and contracted at pleasure, as the nature of the work may require.

The invention is designed to facilitate the construction of planes and render them more perfect than those of ordinary construction.

To enable those skilled in the art to fully understand and construct my invention I will proceed to describe it.

A, represents the plane stock, which is formed of a wooden center a, a’, with a metal strip or plate b, at each side. The back part a’, of the wooden part of the stock is permanently attached to the metal plates b, b, but the front part a, is adjustable, that is to say, it is allowed to slide longitudinally between the plates b, b, and nearer to or farther from the part a’, of the central wooden portion as may be desired, — the part being secured at any desired point by set screws ax, ax.

The throat c, of the plane is formed between the parts a, a’, of the central wooden portion of the plane, the front end of the part a’, being inclined, as shown at d, and the back end of the part a, having a double inclined surface, as shown at e, f. This form of the adjoining ends of the parts a, a’, constitute the throat, and as the part a, is adjustable the throat it may be seen may be enlarged or contracted as desired.

The lower edges of the metal slides b, b, do not quite extend down to the bottom of the wooden portion a, a’, of the stock, and consequently the bottoms of the wooden portion a, a’, constitute the “sole” of the plane. The iron B, is of usual form and is fitted against the end d, of the part a’, and secured thereto by a wooden key or wedge g, which is driven behind flanches h, h, formed on the inner sides of the plates b, b, — the flanches being cast with the plates b, b.

From the above description it will be seen that the plane may be very readily constructed, much more so, than if made entirely of wood in the ordinary way. The throat c, is formed or made without difficulty and its orifice at the cutting edge of the iron B, may be contracted or enlarged as occasion may require. The plates b, b, may be of cast metal, and the central part a, a, may be of beech or other similar wood.

Having thus described my invention what I claim as new and desire to secure by Letters Patent, is,

Constructing the plane stock of a central wooden portion a, a’, secured between metal side plates b, b, provided with flanches h, h, the part a’, being permanently secured between the plates b, b, and the part a, rendered adjustable between said plates by set screws ax, ax, substantially as and for the purpose set forth.

JACKSON GORHAM.

Witnesses:

GEO.W. NEAL,

WM. O. CHENEY, Jun.