No. 309,400 – Joiner’s Plane (George D. Mosher) (1884)

UNITED STATES PATENT OFFICE.

_________________

GEORGE D. MOSHER, OF BIRMINGHAM, CONNECTICUT.

JOINER’S PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 309,400, dated December 16, 1884.

Application filed November 3, 1884. (No model.)

_________________

To all whom it may concern:

Be it known that l, GEORGE D. MOSHER, of Birmingham, in the county ot’ New Haven and State of Connecticut, have invented a new lmprovement in Joiners’ Planes; and l do hereby declare the following, when taken in connection with accompanying drawings and the letters of reference marked thereon, to be a full, clear, and exact description of the same, and which said drawings constitute part of this specification, and represent, in —

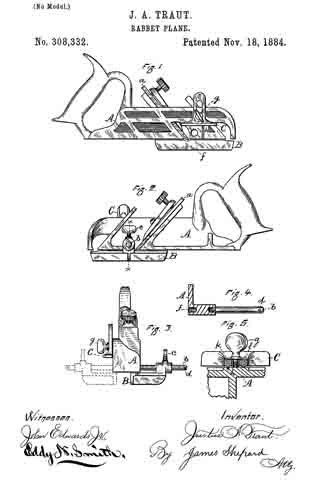

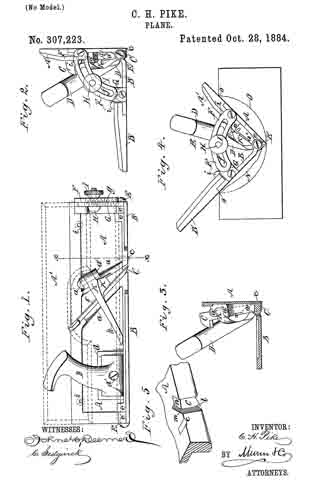

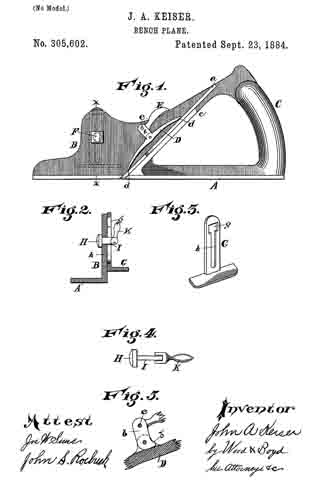

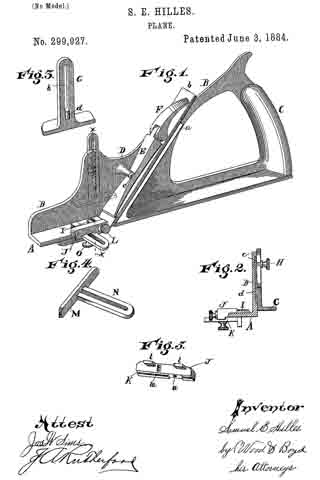

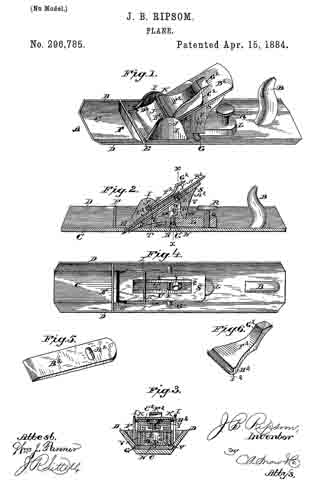

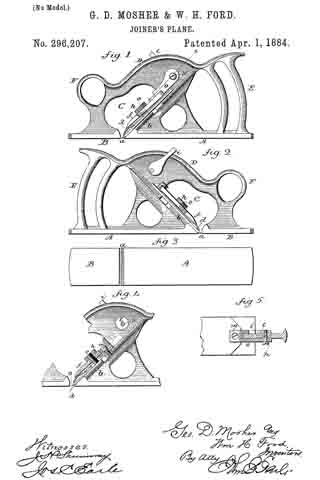

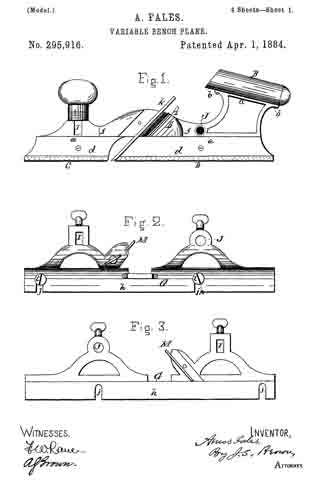

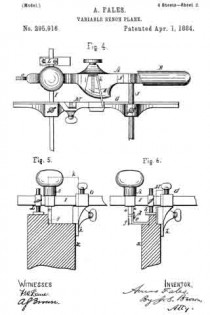

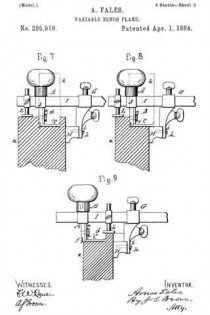

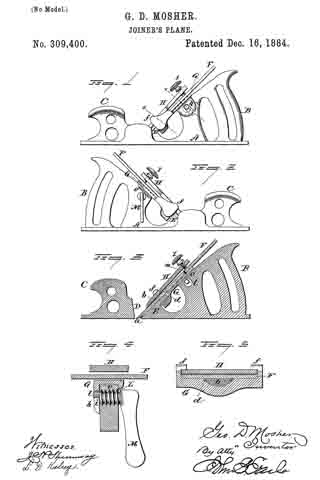

Figure 1, a left-hand side view; Fig. 2, a right-hand side view; Fig. 3, a longitudinal central section; Fig. 4, a transverse section on line x x of Fig. 1; Fig. 5, a transverse section on line z z of Fig. 1.

This invention relates to an improvement in that class of joiners’ planes which consist of a cast-metal stock fitted with a clamping device to hold the cutter, and mechanism for adjusting the cutter with relation to the mouth, the object of the invention being to simplify the construction, so that the plane may be produced with very little mechanical labor, and thereby greatly reduce the cost; and the invention consists in the construction, as hereinafter described, and more particularly recited in the claims.

A represents the base or plate of the stock, fitted at one end with a handle, B, and may be at the other with a handle, C, and with the usual transverse mouth, a, opening into the throat D. Imrnediately in rear of the throat is a bearing, E, inclined to the position required for the cutter, and upon which the lower end of the cutter F may lie. Centrally from this bearing E a lug, b, extends upward, inclined corresponding to the incline of the bearing-surface E.

G is the bed for the cutter. At its lower end it is constructed with a recess, d, upon its face side, corresponding, substantially, to the lug b, as seen in Figs. 3 and 5. The face of the cutter-bed G forms, substantially, a continuation of the inclined bearing E, as seen in Fig. 3. The upper end of the bed G is constructed with a groove upon its under side, to ride upon a guide, c, formed on the handle portion above the bearing-surface E. The groove is best formed by a rib or flange near each edge of the upper part of the bed, to embrace the bearing e, as seen in Fig. 4. The bed is constructed with a hook, f, upon each side near its lower end, these hooks formed by extending or turning the edge upward and inward, as seen in Fig. 5.

H is the cap for the cutter, provided at its upper end with a set-screw, I. The hooks are of such extent that the cutter F may be set down between them and the bed, and then the cap H introduced between the cutter and the hooks, as seen in Figs. 3 and 5, the cap extending down toward the edge of the cutter, the screw taking its bearing upon the cutter above the hooks. Thus introduced, the screw is turned to a bearing upon the cutter, forcing the cutter firmly against the bed G, and causing the lower end of the cap to turn inward against the cutter and clamp the cutter upon the bearing E, as seen in Fig. 3, so as to firmly secure the cutter in its place. The cap may be adjusted to any desired relation to the edge of the cutter, so that it may serve as the cap for the cutter to govern the depth of the cut, if desired.

To adjust the cutter the bed G is constructed with a flange, h, upon one side of the handie portion, as seen in Figs.1 and 4. This flange is constructed with a notch or opening, i. Through the handle portion a coarse-threaded screw, L, is introduced, the handle portion being correspondingly screw-threaded, as seen in Fig. 4. This screw is provided with an eccentric stud, Z, which stands in the slot ffl of the bed, and so that if the screw be turned to iinpart a cranlrdilre nrovenient to the stud l, it will correspondingly move the bed G up or down, according to the rotation of the screw E. Upon the reverse side the screw is provided with a handle, M, by which it may be conveniently turned. The screw-thread on this adjusting device imparts a longitudinal movement to the stud l as the screw is turned, hence produces a transverse friction between it and the surface of the notch i in which it works, in addition to the friction which naturally arises from the rotative bearing of the stud. Such transverse friction adds materially to the hold which the stud takes upon the bed, so that accidental displacement is not liable to occur, as would be the case were the screw E constructed with simply a cylindrical surface in the stock, and so that rotative movement only would be imparted to the adjusting-stud l. By this construction the stock is readily molded and cast complete, the cleaning and preparation of the casting to receive the cutter and bed being an inconsiderable operation. The bed G is also cast complete, ready for application to the stock without any material mechanical labor, and thus I produce a plane at a minimum cost, yet complete and perfect in its working and adjustment.

To prevent the possibility of the cutter being thrown out of adjustment by contact with knots, or other extraordinary hard attacks in operation, I construct the face of the bed with a series of notches on its face, and provide the cutter with a corresponding stud, in, (see Fig. 3,) and so that when the cutter is set in place the stud may enter one of the notches in the bed and there hold firmly, so that any adjustment of the bed must be necessarily irnparted to the cutter, and the notch and stud serve to resist any tendency of the work to throw the cutter out of adjustment.

I claim —

1. The metal stock, constructed with the inclined bearing E in rear of its mouth, and with the lug b extending upward and backward therefrom, the bed G, constructed with a recess, d, upon its face, corresponding to the said lug D, said bed also constructed with hooks f f, and arranged to take a bearing on the stock above the said lug, combined with the cutter F, cap H, and the set-screw I in said cap, substantially as described.

2. The metal stock, constructed with an inclined bearing, E, in rear of its mouth, and with a lug, b, extending upward and backward therefrom, the bed G, constructed with a recess, d, corresponding to said lug, and arranged to take a bearing on the stock above, and also constructed with hooks f f, and with a downwardly-projecting flange having a notch, i, therein, the cutter F, cap H, and set-screw I, with the screw E transversely through the stock, said screw provided with an eccentric stud, l, at one end to work in said notch i, the opposite end provided with a handle, M, substantially as and for the purpose described.

3. The stock constructed with the inclined bearing E in rear of its mouth, and with the lug b extending upward and backward therefrom, the bed G, constructed with a recess, d, corresponding to said lug, and also with hooks f f, the said bed arranged to take a bearing upon the stock above the said lug b, the face of the said bed constructed with a series of notches, the cutter constructed with a stud, m, upon its under side to engage either of said notches, the cap H, and set-screw I, substantially as described.

GEORGE D. MOSHER.

Witnesses:

THOS. L. I. BULLUSS,

WM. H. WILLIAMS.