No. 485,923 – Truing Device For Bench-Planes (John Porcius Gage) (1892)

UNITED STATES PATENT OFFICE.

_________________

JOHN PORCIUS GAGE, OF VINELAND, NEW JERSEY.

TRUING DEVICE FOR BENCH-PLANES.

_________________

SPECIFICATION forming part of Letters Patent No. 485,923, dated November 8, 1892.

Application filed March 31, 1892. Serial No. 427,209. (No model.)

_________________

To all whom it may concern:

Be it known that I, JOHN PORCIUS GAGE, a citizen of the United States, and a resident of Vineland, in the county of Cumberland and State of New Jersey, have invented certain new and useful Improvements in Truing Devices for Bench-Planes; and I do declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it appertains to make and use the same, reference being had to the accompanying drawings, and to letters of reference marked thereon, which form a part of this specification.

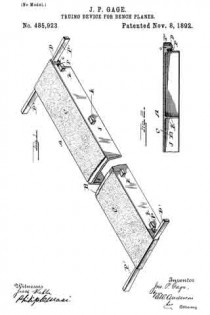

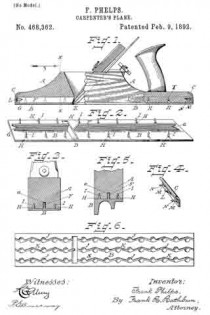

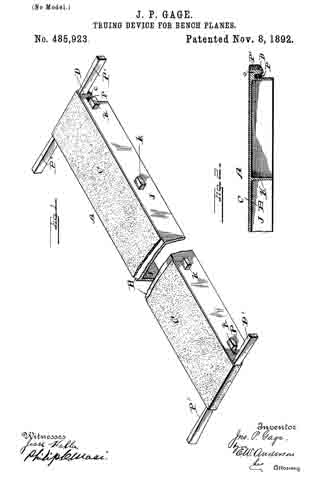

Figure 1 of the drawings is a representation of the device and is a perspective view. Fig. 2 is a longitudinal section of same.

This invention relates to certain novel devices for truing up or facing off the working or face side of carpenters’ bench-planes; and it consists in the novel construction and combination of parts, as hereinafter specified.

The invention more particularly consists in providing an abrasive surface held upon a suitable support in such a manner that all parts thereof will in so far as possible lie in the same plane, so that by rubbing the working face of the plane over such surface said face will be left perfectly true and smooth, which is a necessary qualification for a tool of this character. For truing up wooden planes this abrasive surface consists in a strip of ordinary sandpaper arranged in the manner above specified, while with metal planes emery-paper is employed.

In the accompanying drawings I have illustrated a convenient and effective manner of arranging the abrasive material, which consists in providing an elongated frame or table A, formed from a heavy metal casting having the horizontal portion B, the surface of which is in so far as possible a true plane, and is supported by the integral vertical depending flanges J, reinforced at intervals by the transverse portions K. Along the lateral outer faces of the flanges J are projecting lugs k, located at intervals, by means of which the table may be rigidly held in a stationary position in a suitable block or support. Over the upper surface of the horizontal portion B is tightly stretched a strip of sand or emery paper C, which is made secure at its ends in such a manner as to insure against an endwise or lateral displacement. In the drawings I have shown this as effected by bringing the ends of the paper over the ends of the frame or table and under depending flanges c, between which flanges and the ends D of the table are driven wedges P. Tapered wedges P are also driven under the paper from opposite sides against the flanges c. Should the paper become slack, these wedges may be driven in a greater distance. The heavy casting forming the table or support forms an effective means for the purpose, in that it is free from any vibration and renders the operation of the device very satisfactory. It will be understood, however, that I do not desire to limit myself to any especial devices for holding the paper in place, as such devices may be varied without departing from the spirit and scope of this invention.

Having described this invention, what I claim, and desire to secure by Letters Patent, is —

The herein-described device for truing up the working faces of bench-planes and other articles, said device comprising a heavy oblong rectangular metal casting having a true upper horizontal surface and formed at its ends with the under transverse lugs and a strip or piece of material provided with an abrasive surface stretched tightly over the true surface of said casting, the ends of said strip or piece being extended over the ends of the casting and clamped in said under transverse lugs, substantially as specified.

In testimony whereof I affix my signature in presence of two witnesses.

JOHN PORCIUS GAGE.

Witnesses:

JOHN S. GAGE,

W. W. BENTHALL.