No. 978,471 – Rabbeting-Plane (Judd W. Montague) (1910)

UNITED STATES PATENT OFFICE.

_________________

JUDD W. MONTAGUE, OF COLUMBUS, OHIO, ASSIGNOR OF

ONE-HALF TO CHARLES H. NOBLE, OF COLUMBUS, OHIO.

RABBETING-PLANE.

_________________

978,471. Specification of Letters Patent. Patented Dec. 13, 1910.

Application filed June 7, 1910. Serial No. 569,035.

_________________

To all whom it may concern:

Be it known that I, JUDD W. MONTAGUE, a citizen of the United States, residing at Columbus, in the county of Franklin and State of Ohio, have invented a certain new and useful Improvement in Rabbeting-Planes, of which the following is a specification.

This invention relates more especially to planes intended for cutting rabbets in straight or curved corners of wood and for beveling or rounding such corners but the invention can be used for planing flat surfaces.

The object of the invention is to provide a tool of this kind that shall be of simple and economical construction and of easy manipulation.

The invention is embodied in the construction and combination of parts herein shown and described and then pointed out in the claims.

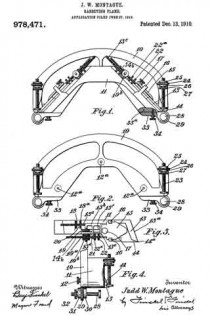

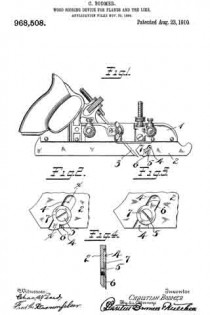

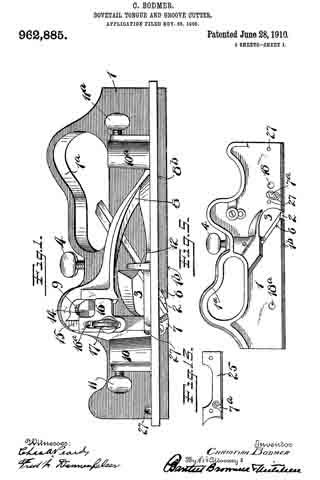

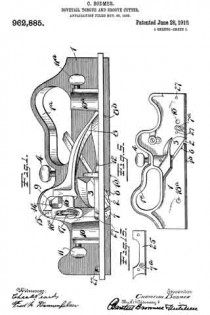

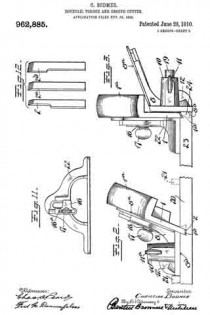

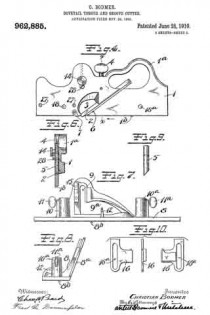

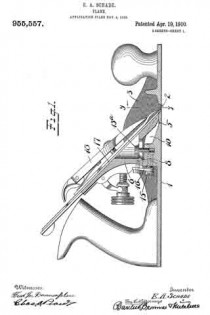

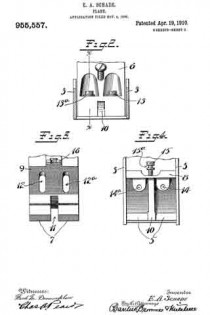

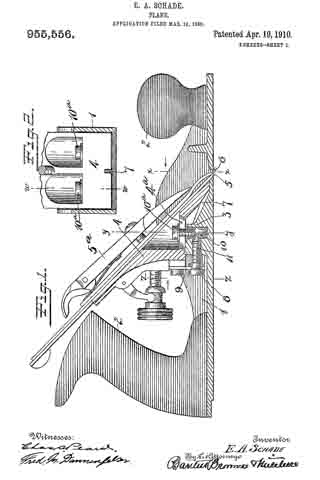

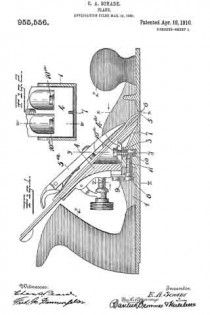

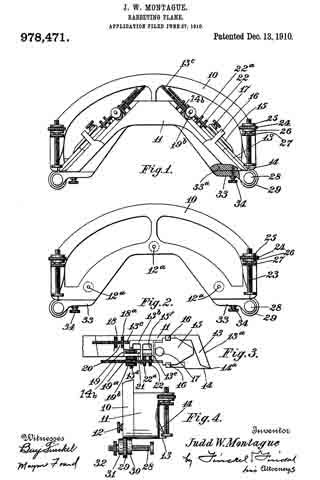

In the accompanying drawing Figure 1 is a view of that side of the device containing the chisels or bits and adjusting devices therefor a small portion being broken out to show a detail. Fig. 2 is a side view of the mainframe with the bit receiving frame removed. Fig. 3 is a top plan view of the bit and knife with the devices for holding and adjusting them. Fig. 4 is a view of the left hand end of the tool as shown in Fig. 1, to illustrate the guides.

In the views 10 designates the main frame and 11 the stock or bit carrying frame. These two frames are of arch form and the stock is secured to the side of the main frame by means of suitable screws such as seen at 12 passed through the three holes at 12a, 12a 12a (see Fig. 2) into holes tapped in the stock so that when the two are secured together they appear as in Fig. 1.

The stock or bit carrying frame is equipped with a bit and knife at each end so that the implement can be used for either right hand or left hand work or by forward or rearward operation. As the equipment at each end is symmetrically like that at the other in construction and arrangement a description of one equipment will suffice for both.

Referring more particularly to Fig. 3 which best illustrates the cutting equipment and the adjusting devices therefor, the character 13 designates the chisel or bit and 14 the knife the former having an ordinary slanting edge 13a and the latter a short cutting edge 14a standing at right angles to the forward portion of the slanting edge of the bit so that the two together cooperates at the forward portion of said slanting edge to cut out a corner. The shank portion of the knife is superimposed on that of the bit and is held thereon by a clamping piece or cap 15 placed under lips 16 extending upward and inward from the carrying frame or stock 11 said piece 15 being provided with a set screw 17 pinching the upper side of the knife.

The shank 13b of the bit is provided with a longitudinally extending screw 13c, a laterally extending screw 13d, and a lateral recess providing walls 13e and 13f. The screw 13e is provided with two nuts 18 and 18a and the screw 13d is provided with nuts 19 and 19a and 19b, The nuts 18 and 18a project at their lower portions into a recess 20 in the bit stock and can be turned on the screw against the walls of said recess to lock the bit shank and bit from movement longitudinally on the stock and the lower portion of the nut 19 projects into a groove 21 in the stock to prevent lateral movement of the bit shank. The shank of the knife 14 is provided with a screw 14b having thereon two nuts 22 and 22a that project into the lateral recess of the bit shank and can be turned against the walls 13e and 13f of the recess forming them to prevent longitudinal movement of the knife blade on the bit; and the screw of the knife shank lies between the nuts 19a and 19b and is prevented from movement laterally with reference to the bit by said nuts, when these are turned to lie against said screw. From this construction it will be observed that the bit can be given its proper position on the stock and the knife can be given its proper position on the bit, and further that when the knife is placed in proper position with reference to the bit both together can be adjusted to proper position.

Each end of the bit-carrying frame is provided with a guide to contact with the upper side of the wood to be rabbeted, beveled or rounded, said guide consisting of a vertically arranged headed screw 23 having on it a nut 24 said nut being located between fixed lateral projections or bars 25 and 26 on the side of the bit carrying frame and a nut 27 to pinch the under side of the projection 26 after the screw or guide has been properly adjusted. Each end of the main frame is provided with a guide to contact with the vertical or upright side of the wood to be rabbeted, beveled or rounded, said guide consisting of a horizontally arranged headed screw 28 having on it a nut 29, said nut being located between fixed projections or ears 30 and 31 on the main frame and a nut 32 to pinch the outer ear 31 after the screw or guide has been properly adjusted. The ears or projections 30 and 31 are formed on a block 33 detachable from the foot of the frame, said block being provided with a pin 33a to enter a socket in said foot and a set screw 34 screwed into a suitable hole in the foot. This block 33 and its contained guide can be removed and the plane used for planing fiat or other surfaces.

The arched form of the main frame and the bit carrying frame when combined permit the gripping of the device with the hand at either end according to the direction in which it is desired to push the device. The planing operation can be performed by either pushing or drawing the device and with the tool grasped either in left hand or right hand manner. In other words the manipulation of the plane can be accommodated to the grain of the wood and so as to avoid as far as practical planing against grain. The knife insures a smooth clean surface at the upright or vertical side of the rabbet. With this construction, and particularly because the cutting corner is free from obstructing parts in front of it two rabbets can be made with great facility in circular, oval or other curved pieces such for example as picture frames and other like structures.

What I claim is:

1. In a plane, the combination with a stock, of a bit with means in connection therewith for longitudinally and laterally adjusting the same with reference to the stock, a knife to angularly cooperate with the cutting edge of said bit, and means connected with the bit and knife for operating the knife to adjust the same with reference to the bit, the knife being movable by moving the bit.

2. In a plane, the combination with a guiding and holding stock, of a removable bit and a removable angularly cooperating knife on the bit, means on the bit for operating the knife to adjust the same with reference to the bit, and means for fixing both the bit and knife to the stock with their cutting edges wholly forward of the material of the stock.

3. In a plane, the combination with a stock, a bit and a knife, means for securing the knife to stand at one end of the edge of the bit and at an angle to the edge of the bit to form a cutting corner, combined with an arched handling frame 10 and means for securing the stock thereto at the side of the latter opposite that containing said cutting corner.

4. In a plane the combination with the stock having a recess 20 and a groove 21 of a bit provided with a longitudinally extending screw 13c and a laterally extending screw 13d and a lateral recess providing walls 13e and 13f, nuts 18 and 18a on the screw 13c extending into said recess 20 and nuts 19 and 19a and 19b on said screw 13d, the nut 19 projecting into said groove 21, a knife having its cutting edge standing at an angle to the cutting edge of the bit and cooperating therewith, said knife provided with a longitudinally extending screw 1 having nuts 22 and 22a thereon projecting between the walls 13e and 13f and said screw lying between the nuts 19a and 19 whereby the bit can be adjusted independently of the knife and the knife independently of the bit, substantially as described.

5. In a plane the combination with the stock having a recess 20 and a groove 21, of a bit provided with a longitudinally extending screw 13c and a laterally extending screw 13d and a lateral recess providing walls 13e and 13f, means on the screw 13c extending into said recess 20 to adjust and fix the same with reference to the stock, and nuts 19 and 19a and 19b on said screw 13d, the nut 19 projecting into said groove 21, a knife on the bit having its cutting edge standing at an angle to the cutting edge of the bit and cooperating therewith, said knife provided with a longitudinally extending screw 14b having means thereon to engage the aforesaid walls 13e and 13f to longitudinally adjust and fix the same and said screw lying between the nuts 19 and 19a, whereby the knife can be adjusted independently of the bit and the bit independently of the knife, substantially as described.

JUDD W. MONTAGUE.

Witnesses:

CHAS. H. NOBLE,

BENJ. FINCKEL.