No. 1,048,455 – Plane (James M. Burdick) (1912)

UNITED STATES PATENT OFFICE.

_________________

JAMES M. BURDICK, OF NEW BRITAIN, CONNECTICUT, ASSIGNOR TO THE STANLEY RULE &

LEVEL COMPANY, OF NEW BRITAIN, CONNECTICUT, A CORPORATION OF CONNECTICUT.

PLANE.

_________________

1,048,455. Specification of Letters Patent. Patented Dec. 24, 1912.

Application filed July 11, 1912. Serial No. 708,840.

_________________

To all whom it may concern:

Be it known that I, JAMES M. BURDICK, a citizen of the United States, residing at New Britain, Hartford county, State of Connecticut, have invented certain new and useful Irnprovements in Planes, of winch the following is a full, clear, and exact description.

This invention relates to an improvement in the construction of planes, and is more particularly concerned with the construction of a detachable cap piece for the cutter or “plane iron”. In such cap pieces, it has hitherto been the practice to provide a detachable cap piece provided with means for engaging with the cutter and clamping it in position upon its seat upon the plane body.

My present invention contemplates employing such a cap piece in the form of a main body portion provided with a palm rest and carrying a relatively movable clamping member adapted to be positioned to engage and clamp the cutter on its seat and to lock said cap piece against movement relative to the plane body.

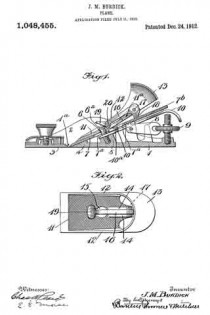

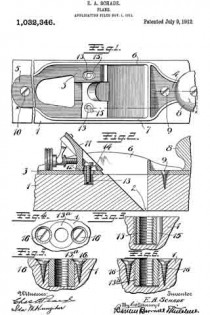

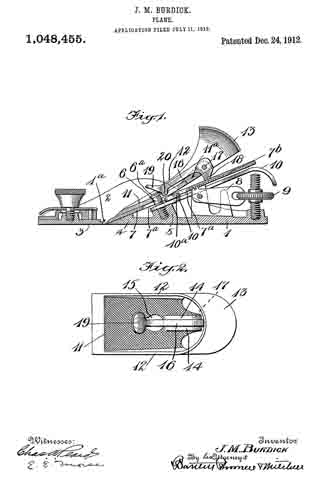

In the drawings illustrating a preferable embodiment of the invention: Figure 1 is a longitudinal section through a standard type of plane equipped with a detachable cap constructed in accordance with the present invention. Fig. 2 is a top plan view of said cap removed from the plane body.

Referring to the drawing by numerals: 1 designates the body of a plane provided with side walls or fianges 2 and a detachable shoe 3 at the forward end thereof, a throat 1a being formed at the forward end of the plane and in the rear of the detachable shoe portion thereof. 4 designates a frog or seat for the forward end of the “plane iron” or cutter, and 5 an interiorly threaded boss projecting upwardly from the plane body and carrying what is commonly termed a “cap screw” 6 provided with the usual headed end 6a. An adjusting lever 10 has its forward end seated over the boss 5 and is provided with an adjusting head 10a. To the rear of said head is a second adjusting device comprising a lever member 8 pivotally mounted at its forward end in the plane body and engaged at its rear end by an adjusting nut 9. A “plane iron” or cutter 7 is seated on the body of the plane with its forward end resting upon the frog or seat 4 and its cutting edge projecting into the throat 1a, the intermediate portions of the cutter resting respectively over the forward ends of the adjusting lever 10 and of the second adjusting lever 8. This cutter is provided with the usual longitudinal slot through which the cap screw 6 projects and through and within which the adjusting head 10a extends, and with a plurality of corrugations 7b formed in its under face which are engaged by the forward end of the adjusting lever 8 to effect vertical adjustment of the cutting edge of the cutter. The lever 10, through its adjusting head 10a, effects lateral or angular adjustment of said cutting edge.

The parts so far described are merely those of a standard type of plane which has been selected for the illustrative application of the detachable cap embodying the invention. This cap is formed as a main body portion comprising a base portion 11 adapted to be seated over the cutter and having side walls or flanges 12 extending longitudinally thereof and beyond the end of the base portion 11, said flanges being widened and joined to form the rounded hollow palm rest 13. The base portion 11, at its rear end, is formed with a slot 11a and with spaced ears 14 extending upwardly from said base portion at the rear end thereof and positioned on either side of said slot. Intermediate its ends, and forward of the ears 14, the base portion 11 is provided with a key-hole slot 15. A clamping lever 16 is pivotally mounted adjacent its rear end between the ears 14, said end extending downwardly between the ears 14 and through the slotted portion 11a and being formed at its extremity as a cam 18. This lever 16 extends forwardly to a point adjacent the key-hole slot 15 and is provided at its forward end with an upwardly extending handle or finger piece 19 and adjacent said handle, with a locking shoulder 20 extending downwardly therefrom. This shoulder is posi-

tioned to lie in substantial alinement with the rear end of the narrowed portion of the key-hole slot 15. The main body portion, with its ears 14, side walls 12 and rearward extension 13 forming the palm rest, may be, and preferably is, formed as an integral structure.

With the foregoing construction of the parts in mind, the application and operation of the cap is as follows: Assuming that the cutter 7 is seated on the plane body as shown in Fig. 1 with the cap screw 6 extending up through its slotted portion 7a, the detachable cap is seated over the cutter by bringing the enlarged end of the key-hole slot 15 in its base over the head of the cap screw 6 and then moving the body portion upwardly to bring the narrowed portion of the slot under the head 6a of the cap-screw. When this has been done, the operator grasps the handle 19 of the clamping lever and moves it downwardly to bring the cam 18 into frictional clamping engagement with the upper face of the cutter 7 (or, when a clamping plate is employed in conjunction with the cutter, with the upper face of said clamping plate). When the cam has been thus moved to clamping engagement with the cutter, the locking shoulder 20 will have been moved over the head 6a of the cap screw and will abut and be locked thereagainst by reason of the frictional engagement of the cam 18 with the cutter 7. From this, it will be evident that the cutter is firmly held on its seat and that the cap cannot be accidentally moved longitudinally of the plane body to break the clamping engagement of the cam 18 therewith. The frictional clamping engagement of the cam with the cutter is such that it is sufficient to retain the cutter fixed on the seat under ordinary conditions of service, but permits adjustment of the cutter by suitable means without disturbing or loosening the cap.

While I have shown and described a specific embodiment of a detachable cap, various modifications and changes in structure thereof are possible within the spirit of the invention and the scope of the appended claims.

What I claim, therefore, and desire to secure by Letters Patent, is:

1. In a plane, in combination, a plane body provided with a cutter seat, a cutter positioned thereon, an abutment carried by said plane body, and a detachable cap for said cutter comprising a main body portion adapted to be seated over said cutter and a palm rest connected to said main body portion and a relatively movable member carried by said body portion and adapted to be positioned to engage and clamp said cutter on its seat and to engage said abutment and lock said body portion against movement relative thereto and to said plane body.

2. In a plane, in combination, a plane body provided with a cutter seat, a cutter positioned thereon, an abutment carried by said body portion, and a detachable cap for said cutter comprising a base adapted to be seated over said cutter to engage said abutment and a paim rest extending rearwardly of said base, and a clamping lever pivotally carried by said cap and formed for simultaneous engagement with said abutment and said cutter whereby said lever may be actuated to engage and clamp said cutter on its seat and also to simultaneously engage said abutment and lock said body portion against movement relative to said plane body.

3. In combination with a plane body provided with a cutter seat and with an upwardly projecting abutment, a detachable cutter cap comprising an integral body portion embodying a base adapted to be seated over the plane cutter and to engage said abutment, and a portion extended rearwardly of said base to form a palm rest, and a lever pivoted adjacent one end to said rearwardly extending portion and having said pivoted end provided with a cutter-clamping cam and having its outer end formed with a locking shoulder adapted to engage said plane abutment when said lever is moved to cutter clamping position, thereby locking said body portion against movement relative to said abutment and to said plane body.

JAMES M. BURDICK.

Witnesses:

I. W. CHAPMAN,

W. J. WORAM.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________

It is hereby certified that in Letters Patent No. 1,0143,455, granted December 24, 1912, upon the application of James M. Burdick, of New Britain, Connecticut, for an improvement in “Planes,” an error appears in the printed specification requiring correction as follows: Page 2, line 50, after the word “cutter” insert the words to engage said abutment; and that the said Letters Patent should be read with this correction therein that the same may conform to the record of the case in the Patent Office.

Signed and sealed this 28th day of January, A. D., 1913.

[SEAL]

C. C. BILLINGS,

Acting Commissioner of Patents.