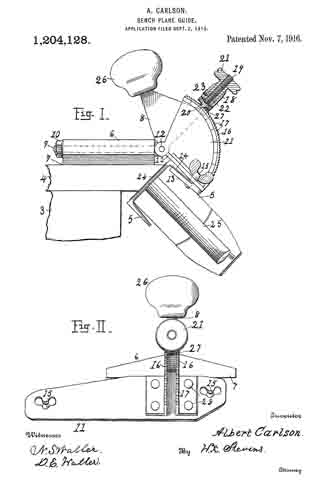

No. 1,204,128 – Bench-Plane Guide (Albert Carlson) (1916)

UNITED STATES PATENT OFFICE.

_________________

ALBERT CARLSON, OF SEATTLE, WASHINGTON.

BENCH-PLANE GUIDE.

_________________

1,204,128. Specification of Letters Patent. Patented Nov. 7, 1916.

Application filed September 2, 1915. Serial No. 48,712.

_________________

To all whom it may concern:

Be it known that I, ALBERT CARLSON, a subject of the Crown of Sweden, residing at Seattle, in the county of King and State of Washington, have invented certain new and useful Improvements in Bench-Plane Guides, of which the following is a specification.

This invention relates to carpenters’ tools, and its object is to produce an attachment for bench-planes designed to guide the plane to cut at some given angle relatively to a plane of the work.

To this end my invention consists in the construction and combination of parts forming a bench-plane guide hereinafter more fully described, and particularly stated in the claims, reference being had to the accompanying drawing, in which;

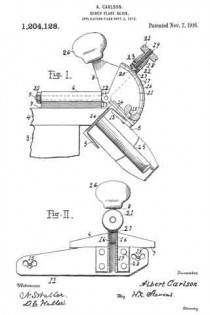

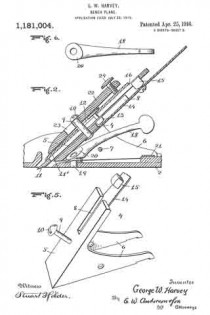

Figure I is an end view, partly in section, of a bench-plane guide according to my invention, carrying a plane in position for work. Fig. II, is a righthand view of the said guide.

Let numeral 3 represent a carpenter’s bench, 4 a board laid thereon to have its edge beveled, and 5 a plane in position for work. I provide a block 6 with a plane face 7 to slide upon the work, a body 8 with a pivotal bolt 9 passing through the block 6, and a screw nut 10 to secure it rigidly to the block when set at the desired angle. A carrier 11 is pivoted at 12 to the body and provided with clips 13 to engage the plane 5 at a side edge 14, and thumb-screws 15 to rigidly secure the clips. This carrier comprises a pair of segments 16, one attached at each side of the body 8, and having arcs of teeth 17 concentric with the pivot 12. A sleeve 18 mounted on a screw-threaded arm 19 of the body, is shaped at 20 as a detent to engage the notches 17, and it is impelled into engagement therewith by a nut 21 that is threaded upon the screw 19. An annular groove 22 in the nut is engaged by a stud 23 which is screwed through the sleeve, whereby the backward turning of the nut withdraws the detent 20. The segment 16 may be stamped with figures indicating in degrees, the angle being formed on the work at that set. Or numerals may indicate the points where the detent is to be set to level boards to match together in forming posts of 6, 8, or 10 sides, or other forms desired.

By using the turnbolt 9 as a pivot the body 8 and carrier 11 may be set at a longitudinal pitch to fix the plane edge 24 either at rightangles with the edge of the work, or obliquely thereto when it is desired to give a peeling cut. The sleeve 18 has a tang 27 entering between the segments 16 to keep it from turning with the nut 21. Rivets 28 are shown as means for attaching portions of the carrier together. The block 6 may be of any suitable material. By seizing the handle 25 with one hand and the knob 26 on body 8, with the other hand this device may be operated with ease, producing accurate work without requiring repeated trials to fit the bevel-square. It is reliable and inexpensive.

I claim:

I. In a bench plane guide, a block having a plane face to slide on; a carrier having means for securing a plane to it; a body member intermediate between the said block and carrier, this body member having pivotal connection with the said block, the line of the pivot being transverse to the line of travel of the plane, and the carrier having pivotal connection with the intermediate body member the line of the pivot being in the direction of the line of travel of the plane.

2. In a bench plane guide, a block to slide; a plane carrier, and an intermediate body pivotally connected with each, the pivots of the two connections being in lines at right angles to each other.

In testimony whereof I affix my signature in presence of two witnesses.

ALBERT CARLSON.

Witnesses.

R. E. CRYDER,

GEO. M. SALMON.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________