No. 1,249,674 – Plane-Spur (Edmund A. Schade) (1917)

UNITED STATES PATENT OFFICE.

_________________

EDMUND A. SCHADE, OF NEW BRITAIN, CONNECTICUT, ASSIGNOR TO THE STANLEY RULE & LEVEL CO.,

OF NEW BRITAIN, CONNECTICUT, A CORPORATION OF CONNECTICUT.

PLANE-SPUR.

_________________

1,249,674. Specification of Letters Patent. Patented Dec. 11. 1917.

Application filed June 18, 1917. Serial No. 175,271.

_________________

To all whom it may concern:

Be it known that l, EDMUND A. SCHADE, a citizen of the United States of America, residing at New Britain, Connecticut, have invented a new and nuseful Plane-Spur, or which the following is a specification.

My present invention relates to planes and the general objects of the invention are to provide an improved and more efficient spur construction for rabbet, dado and other planes or similar type.

A special object is to rnaintain the setting or adjustment or the spar with respect to the cutting blade.

ln accomplishing the foregoing, I construct the plane stock with teeth projecting into the spur receiving channel and the spur is constructed with teeth to engage and mesh with the teeth on the stock, these teeth being disposed so as to resist the strain exerted on the spur and to thereby rnaintain the spur in its adjusted position. Usually the teeth on the steel are provided hy a hard metal insert seated in the body out the stock.

The accompanying drawing illustrates the invention embodied in a practical and preferred form, but it will be understood that changes and modifications may be made without departing from the true spirit and scope of the invention.

ln the drawing:

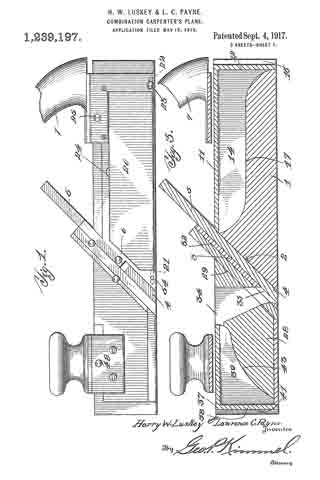

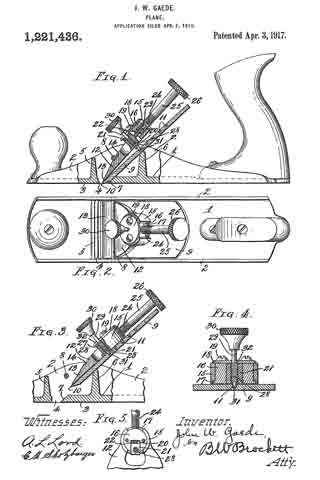

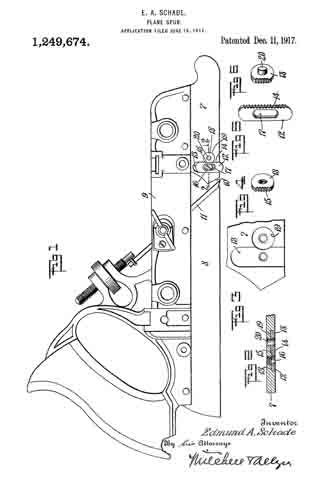

Figure 1 is a view in side elevation of a “Stanley Universal” plane having rny invention incorporated therein.

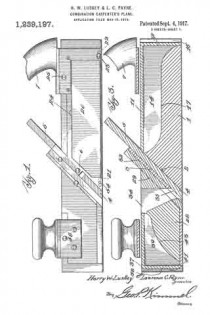

Fig. 2 is a horizontal sectional view taken through the spar construction substantially on the plane of the line 2–2 of Fig. 1.

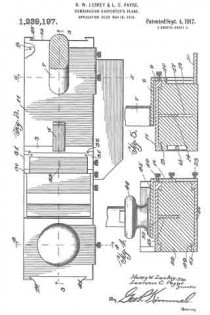

Fig 3 is a fragmentary view of that portion of the plane stock in which the spur receiving channel and the recess for the anchoring element are formed.

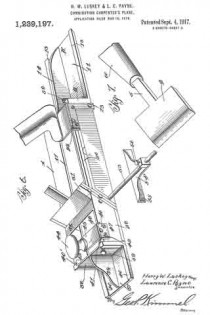

Fig. 4 is a detail perspective view or the so-called anchoring element.

Fig, 5 is a detail perspective view of the spur.

Fig. 6 is a similar view of a modfied form of anchoring element.

The stock or the plane in the case illustrated is formed in front and rear sections 7 and 8 respectively, attached to a back or body member 9, said sections being separated by an angular opening or throat 10 through which the cutter blade 11 projects.

12 designates the spur, located in advance of the cutter and disposed in a channel or seat 13 formed in the side of the front stock section 7. This channel preferably extends substantially at right angles to the cutting plane of the tool, permitting of an up and down adjustment or the spur in the channel for the purpose of setting the spur with respect to the cutter blade, it being understood that the lower cuttiing edge of the spur is usually set slightly below the cutting edge or the blade so as to score the material in advance of the blade.

The spur is locked in its adjusted position in my invention, by providing it on the forward edge thereof with teeth or serrations 14 for engagement with corresponding teeth or serrations 15 on the stock, the spur being held seated in its channel and engaged with the teeth aforesaid by rneans such as a screw 16 extending through a slot 17 in the spur into engagement with a screw seat in the stock at the back or the channel. These interlocking teeth on the stock and spur are disposed in planes substantially parallel to the cutting plane and transversely with respect to the longitudinal adjustment of the spur so as to resist the strain on the spur when the plane is in use.

The teeth on the stock are provicled in the case illustrated by a hard metal disk or washer 18 in the nature of an “insert”, seated in a recess 19 at one side of and opening into the edge portion of the spur receiving channel, this disk having a flattened toothed edge portion projection into the edge part of the channel. The locking or anchor disk 18 may be secured in planes in various ways as by welding or riveting, it being shown in the present instance as held in its seat by a rivet 20. ln Fig. 6 the rivet is shown formed integral with the disk rnember.

This invention rnakes it possible to set the spur to the proper depth with respect to the cutter and to maintain that relation during the subsequent use of the tool and at the same time, it is possible as the cutting edge of the spur wears down, to easily set the spur to at new adjustment or when desirable, to change the position of the spur for cutting in softer or harder woods.

l claim :

1. ln a plane, a stock having a spur receiving channel in one side thereof, a recess in said stock at one side of said channel and opening into the edge of said channel, a hard metal locking device fixed in said recess and having a toothed edge at one side projecting into the side edge of the channel aforesaid, a spur having one edge toothed to coact with the teeth on said locking portion, the width of said spur corresponding to the width of said channel, said spur being adjustably engaged with said locking device by a lateral movement of said spur whereby the degree of projection of said spur below said stock may be controlled, and means for holding said spur against lateral disengagement from said locking device when the latter is in its adjusted operative position.

2. In a plane, a stock having a spur receiving channel in one side thereof, a recess in said stock at one side of said channel and opening into the edge of said channel, a hard metal locking device fixed in said recess and having a toothed edge at one side projecting into the side edge of the channel aforesaid, a spur having one edge toothed to coact with the teeth on said locking portion, the width of said spur corresponding to the width of said channel, said spur being adjustably engaged with said locking device by a lateral movement of said spur whereby the degree of projection of said spur below said stock may be controlled, and means for holding said spur against lateral disengagement from said locking device when the latter is in its adjusted operative position, said holding means comprising a screw passing through a longitudinal slot in said spur and screwing into said stock.

EDMUND A. SCHADE.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________