No. 738,501 – Plane (Alix W. Stanley And Edmund A. Schade) (1903)

UNITED STATES PATENT OFFICE.

_________________

ALIX W. STANLEY AND EDMUND A. SCHADE, OF NEW BRITAIN, CONNECTICUT,

ASSIGNORS TO STANLEY RULE & LEVEL COMPANY, OF NEW BRITAIN,

CONNECTICUT, A CORPORATION OF CONNECTICUT.

PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 738,501, dated September 8, 1903.

Application filed February 11, 1903. Serial No. 142,845. (No model.)

_________________

To all whom it may concern:

Be it known that We, ALIX W. STANLEY and EDMUND A. SCHADE, citizens of the United States, residing at New Britain, in the county of Hartford, State of Connecticut, have invented certain new and useful Improvements in Planes, of which the following is a full, clear, and exact description.

This invention relates to planes, and particularly to improvements in the construction of that class of planes adapted to be used on curved surfaces, sometimes called “circular planes.” In planes of this character the base or sole is made flexible, so that it may be bent to any desired curve to cause the plane to fit onto a curved surface, either concave or convex. The sole portion of the plane is usually made of sheet metal, such as spring-steel. It is highly desirable in planes of this character that means be provided whereby the adjustment of the sole to the desired curve may be effected accurately and quickly. To that end, therefore, the main object of this invention is to provide simple and effective mechanism for attaining these results.

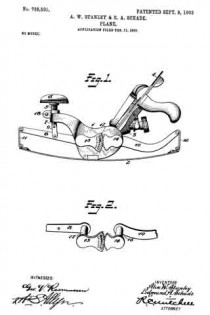

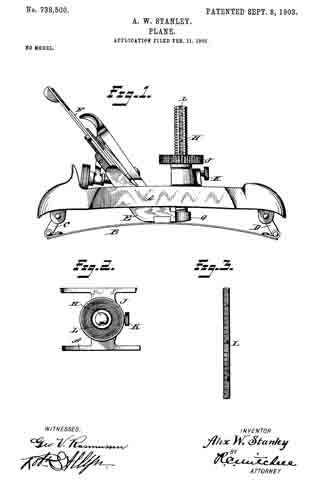

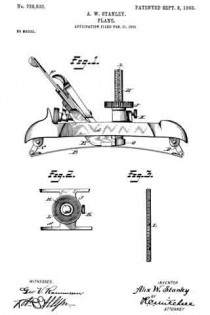

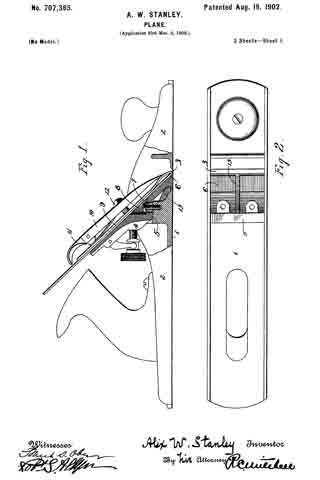

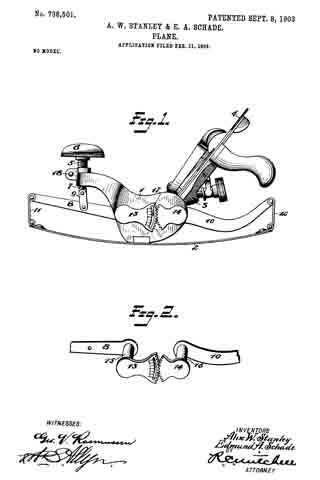

In the accompanying drawings, Figure 1 is a side elevation illustrative of a specific embodiment of my invention, the sole of the plane being curved to fit to a concave surface. Fig. 2 is a fragmentary perspective view of detached details of construction.

1 is the main body portion.

2 is the base or sole portion. The sole portion 2 is capable of being curved relatively to the main body portion 1. In the form shown the portion 1 is connected to the middle portion of the sole 2.

3 is the frog, carried by the frame 1 and in turn supporting the plane-iron 4. and the adjustments therefor. It is not necessary to explain in detail the adjustments for the plane-iron, because they are well known and constitute no part of this invention.

5 is a screw-threaded post mounted in a suitable screw-threaded bearing on the forward part of the body 1.

6 is a knob or handle carried by the post 5. When said post is rotated it will move up and down relatively to the body 1.

7 is a telescopic extension of the post 5. The connection between the post 5 and its extension 7 is screw-threaded. The screw-threads on the post which take into the frame 1 are right-hand threads, while the screw-threads on the extension 7 which take into the post are left-hand threads, or vice versa. The post extension 7 is connected to a lever 8 by means of a link 9. The lever 8 is pivotally mounted in the body 1. The link 9 prevents the extension 7 from rotating. The particular screw-threaded adjustment of the post 5 relatively to the frame 1 and the extension 7 relatively to the post 5 produces double the movement of the lower end of the extension 7 that would be produced were the link 7 merely projected into the post 5 without being oppositely screw-threaded. The lever 8 is connected with one end of the sole 2 by means of the link 11. 10 is another lever pivotally mounted in the body 1 and connected to the opposite end of the sole 2 by the link. 12.

15 is a pivot for the lever 8.

16 is a pivot for the lever 10. 13 14 are segmental gears fixed on the pivots 15 16, respectively, so that the movement of one of said levers will be transmitted to the other — for example, the movement of the lever 8 by the aforesaid means will produce a corresponding movement in the lever 10. Hence as the lever 8 is moved upwardly the sole 2 will be curved upwardly. If the lever 8 is moved downwardly, the sole 2 will be curved downwardly, and the position of the levers 8 and 10 and the degree and direction of curvature of the sole 2 are deterininable solely by the handle 6. By means of a suitable indicating device it may be ascertained whether the sole is flat or curved and if curved what degree of curvature exists in the sole. In the particular form shown the indicating device comprises a pointer 17, carried by one of the parts — for example, the body 1 — in such a position as to project into the path of movement of certain graduations carried by another part — for example, the segmental gear 13. Referring to Fig. 1, it will be seen that the pointer 17 projects into a curved slot in the segmental gear 13, adjacent to which curved slot there are certain graduations from zero upward and downward. These graduations indicate degrees of curvature in the sole. When the zero-mark on the graduated scale lies opposite the pointer or line of reading, it indicates that there is no curve in the sole. If any one of the graduations above the zero-mark is brought into line with the pointer, it indicates to the user that the sole is curved upwardly to a certain definite degree. The reverse is true of the graduations below the zero-mark. It might be said that the segmental gear 13 constitutes a movable pointer, which enables the user to accurately set the plane so that the sole will be curved to any desired degree to fit to any particular curved surface, and this adjustment may be accurately and quickly effected without any preliminary trials, such as fitting the plane to the particular curved surface upon which it is desired to operate. When the plane has been set as desired, a set-screw 18 may be operated to clamp the adjusting screw or post 5 and prevent accidental displacement. The set-screw 18 may operate to clamp a split collar on the frame 1, through which the adjusting-post 5 passes.

The subject-matter disclosed and claimed herein is a specific embodiment of the invention broadly claimed in Alix W. Stanley’s application for United States Letters Patent, Serial No. 142,844, filed February 14, 1903.

What is claimed is —

1. A plane for cutting curved surfaces comprising a body portion, a sole portion secured thereto, adjusting-arms pivotally secured to the body portion and connected to the sole portion, segments of gears carried by the pivotal supports, an index or scale carried by one of said segments, and a stationary indicator or pointer carried by the body portion of the plane coacting with the scale or index whereby the degree of curvature of the sole portion may be indicated.

2. A plane comprising a body portion, a flexible sole portion secured thereto, a pair of arms pivoted in said body portion and connected to the ends of the sole portion, an index or scale carried by one of said arms, and a relatively stationary indicating member carried by the body portion of the plane and coacting with the scale or index for indicating the degree of curvature.

3. A plane for cutting curved surfaces comprising a body portion, a sole portion secured thereto, a pair of arms pivoted to the body portion and connected to the sole portion, gear-segments mounted to operate with said arms, one of said segments being slotted and having a scale or index adjacent the slotted portion, and an indicating member carried by the body portion of the plane cooperating with the scale or index for the purpose specified.

Signed at New Britain, Connecticut, this 7th day of February, 1903.

ALIX W. STANLEY.

EDMUND A. SCHADE.

Witnesses:

ROBERT N. PECK,

WILLIAM J. WORAM.