No. 504,562 – Joiner’s Plane (John M. Cole) (1893)

UNITED STATES PATENT OFFICE.

_________________

JOHN M. COLE, OF CLEVELAND, OHIO.

JOINER’S PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 504,562, dated September 5, 1893.

Application filed April 15, 1893. Serial No. 470,429. (No model.)

_________________

To all whom it may concern:

Be it known that I, JOHN M. COLE, a citizen of the United States, residing at Cleveland, inthe county of Cuyahoga and State of Ohio, have invented certain new and useful Irnprovements in Joiners’ Planes; and I do hereby declare that the following is a full, clear, and enact description of the invention, which will enable others skilled in the art to which it appertains to make and use the same.

My invention relates to improvements in joiners’ planes, and the invention consists in the construction of a plane substantially as shown and described and particularly pointed out in the claims.

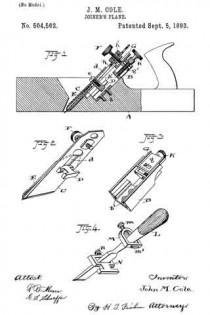

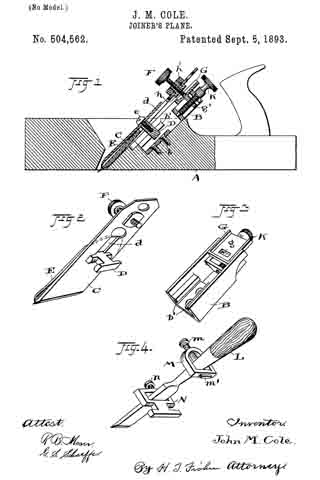

ln the accompanying drawings, Figure 1 is a longitudinal central sectional view of a plane equipped with my improvements. Fig. 2 is a perspective view of the plane irons with the parts which are permanently attached thereto. Fig. 3 is a perspective view of the metal bed which is seated centrally in a recess in the stock, as seen in Fig. 1, and Fig. 4 is a view of a modification of the invention in which an ordinary chisel is shown as being held with mechanisrn corresponding to the holding mechanism for the bit in Fig. 2, and as hereinafter more fully described.

A represents the stock of the plane, and B is a bed which is seated centrally in the body of the stock and fastened thereto by short screws b so as to make a firm and rigid seat for the attachment of the other parts. Connection is made with this bed for the bit or plane iron C by means of the substantially H shaped holder D, secured to the bit C and the cap E through the slot d by means of a screw e, Fig. 1. The bed B has ledges or ribs b’ on its inside along its lower portion which are engaged by the holder D in the relation and rnanner shown more particularly in Fig. 1. This engagement is made by placing the said holder into the recess or opening above the said ledges and then sliding the holder down under the ledges as far as may be necessary, and when thus introduced the said irons C and E and the holder D are firrnly fastened by means of the thumb screw F at the top ot the bit or iron C, which passes through the said bit and bears upon the adjustable bracket G at its inner end. This bracket has a depression or recess g into which the said screw F projects, and by reason of which and the bearing against the ledges b’ through the holder D the bit is prevented from becoming displaced after it has been adjusted and fastened.

For convenience of fastening the screw F in the bit and to give the desired bearing for the screw, I insert a threaded plug h through the hole in said bit and fasten the same by means of a nut h’, the threaded screw h thus adording a long threaded bearing on its inside for the screw F. These two parts h, and h’ of course may be reversed and the screw it may have a head upon the outside and the nut be placed upon the inside of the bit.

The bracket G is adapted to slide between the sides of the bed B, and upon the ledges of the bed immediately beneath the same, and it has a projection g’ with a threaded hole adapted to receive the thumb screw K, which is supported in the webs of the bed B, and is adapted to be rotated within its bearings. Then by turning the screw K the said bracket is carried gradually up or down upon the said bed and with it the parts shown in Fig. 2, when the said parts are sufficiently released to permit of such adjustment. Such release of course is effected through the thumb screw F, which serves to tighten them. This screw may be loosened enough to edect the finest needed adjnstrnent of the bit for cutting deeper or shallower, as may be required, and when this adjustment is accomplished the bit is again fastened by means of the screw F and all the parts are in readiness for use. It will be noticed that by this construction I dispense entirely with the usual clamping plate on the face or the bit, and which is usually arranged to overlap the cap E some distance above. The bed and the parts shown in Fig. 3 are designed to remain fixtures within the stock A while the parts shown in Fig. 2 are bodily removable when connected as there shown, by simply releasing the thumb screw F so as to detach it from the bed.

Having the plane constructed with the parts shown in Fig. 3, and with those shown in Fig. 2 removed, I have a construction remaining which is especially adapted to attach an ordinary ohisel L, shown in Fig. 4. lt is often desirable when a groove of narrow width is to be cut, or a channel plowed, to have a construction which will enable a chisel of greater or less width of edge to be placed on the plane to cut a correspondingly narrow channel. My construction is especially adapted to this conversion of the tool, and by means of the stirrup M having a screw m to engage the shank of the chisel, and a holder N constructed as shown to engage the body of the chisel, I am enabled to use a chisel as effectually as if the plane were originally made for this purpose alone. The holder N takes the place of the holder D in the structure, and has a set screw n to bear down upon the chisel and fix it to the holder, the same as the screw e in Fig. 1. The stirrup M has a slight projection m’ on its bottom adapted to engage in the bracket G where the screw F engages in Fig. 1. The plane may, therefore, be converted from the use of one tool to another with ease and facility, and it is therefore given a range of usefulness which makes it altogether a desirable construction.

The construction and operation of the parts will be clearly understood from the foregoing description and need not be more particularly entered into here.

In lieu of the chisel here shown any equivalent cutter or bit may be used, and a very narrow bit, or one the full width of the bed, or of intermediate size, can be adopted.

When for any reason it is desired to remove the cap E from the bit, as is the case when the bit is to be ground, it is only necessary to loosen the screw e, so that the holder D can be turned in line with the slot in the bit, and then the cap and holder are movable together.

Having thus described my invention, what I claim as new, and desire to secure by Letters Patent, is —

1. A plane provided with a suitable bed having ledges longitudinal on its inside, a separate holder for the bit engaging said ledges, adjusting mechanism at the upper end of the bit to fasten the bit, and an adjustable bracket I or seat on which said mechanism is held, substantially as set forth.

2. The construction herein described consisting of a separate bed hired in the plane stock and having inside ledges, a separate holder for the plane iron orbit locking on said ledges, a longitudinally adjustable bracket at the top of said bed, and a fastening device for the plane iron or bit bearing upon said bracket, substantially as set forth.

3. The plane having a separate bed fixed centrally therein, said bed having longitudinal ribs or ledges upon its inside and a holder and screw to fasten the bit to said ledges, in combination with an adjustable bracket at the upper end of the bit provided with an adjusting screw and fastening and adjusting mechanism for the upper end of the bit resting upon the said bracket, substantially as set forth.

4. The plane stock having a metallic bed fixed therein and a bracket at its upper end adjustable in said bed, in combination with the bit, a substantially H shaped holder and a screw to secure said bit between its ends to the bed, and a screw in the upper end of the bit bearing upon said adjustable bracket, substantially as set forth.

5. The stock and the bed fastened in the stock and provided with ledges on its inside, a holder for the bit constructed to engage and slide on said ledges and to secure the bit, in combination with a bracket in the upper end of the bed, and a screw to adjust the bracket, a threaded bearing in the upper end of the bit and a thumb screw in said bearing engaging said bracket, substantially as set forth.

Witness my hand to the foregoing specifcation this 5th day of April, 1893.

JOHN M. COLE.

Witnesses :

H. T. FISHER,

GEORGIA SCHAEFFER.