No. 865,491 – Bench-Plane (Burton M. Graves And Frank N. Loson) (1907)

UNITED STATES PATENT OFFICE.

_________________

BURTON M. GRAVES AND FRANK N. LOSON, OF LOWVILLE, NEW YORK.

BENCH-PLANE.

_________________

865,491. Specification of Letters Patent. Patented Sept. 10, 1907.

Application filed May 7, 1906. Serial No. 315,549.

_________________

To all whom it may concern:

Be it known that we, BURTON M. GRAVES and FRANK N. LOSON, citizens ol the United States, residing at Lowville, in the county of Lewis and State of New York, have invented certain new and useful Improvements in Bench-Planes, of which the following is a specification, reference being had therein to the accompanying drawing.

Our invention relates to an improved bench plane, and we declare that the following is a lull, clear, concise and exact description thereof sufficient to enable one skilled in the art to make and use the same, reference being had to the accoinpanying drawings in which like letters and numerals refer to like parts throughout.

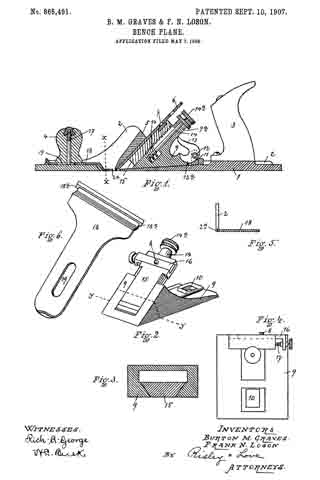

The invention comprises the several utilities shown in the drawings and herein fully pointed out with references to the accompanying drawings, in which Figure 1 is a longitudinal sectional view ot the plane; Fig. 2 is a perspective view of a sliding block which carries the blade; Fig, 3 is a cross section view on the line y–y Fig. 2; Fig. 4 is a view of the block and its adjusting parts taken from the rear; Fig. 5 is a partial section view on the line x–x of Fig. 1 & Fig. 6 is a view of a part.

ln the drawings 1 represents the stock of the plane having the side rails 2, handle 3 and grip 4. The stock is of ordinary construction and as are also the side rails 2 extending from the front to the rear and integral with the stock and being raised torward of the middle to support between them the chipping block 5 which may be made integral or fixed suitably. The blade is represented by 6 and has openings centrally disposed and numbered 7 through one of which pin 8 passes to support the blade.

The parts which support the blade include a sliding member 9 which may be moved to and fro on the upper face of the stock between the side rails. At its rear it has cutout 10 to receive stud 11 which is integral with the stock or fixed thereto and which is pierced at its upper end to receive pin 12 on which cam 13 is pivotally mounted so that its lower portion, indicated by 13a, bears on the front and rear faces of the cutout 10 to move the block 9 to and fro as the cam is turned to crowd the blade into position or to withdraw it. The block 9 has an extension 9a which, together with the block, is suitably grooved and recessed to receive the worm 14 which is operated by the thuinbscrew 14a to be mounted on the stem of the worm after the parts are assembled. On the front and beveled face of the block 9 and dovetailed into it is a slidably mounted adjusting block 15 having its under edge transversely cut to receive the threads of the worm 14 so that by the turning of the worm the block 15 may be raised or lowered. Near the upper end of the sliding block 15 is a dovetail to receive transverse sliding block 16 on which is mounted pin 8 to support the blade 6. The sliding block 16 is upset at the end to carry the screw 17 which engages the sliding block 15 and by the operation oi which the block 16 is moved laterally to give proper side tilt or adjustment to the blade. By the cooperation ol these two adjusting means the blade can be positioned as needed to bring the blade 6 against the chipping block 5.

Ordinarily the adjustment of the blade is made to control the thickness of the shaving, but we have devised a further improvement readily adjustable to conditions without necessitating the troublesome readjustment of the blade after it has once been put in proper alinement and feed. The hand-grip 4 is screw mounted on the pin 17, and between the hand-grip and the stock of the plane we provide plate 18 slotted longitudinally as at 19 lor the pin 17. The inner end of the plate is substantially the width of the space between the side rails 2 and at the end toward the blade is bent downwardly and parallel with the face of the stock. The side rails are slightly notched, as indicated at 2a, and the edges 18a of the plate 18 are extended to fit into said grooves, the grooves being slightly extended to permit to and fro movement of the plate so that the front edge of the plate 18 is slightly wider than the blade 6. By slightly unscrewing the grip 4 the plate can be moved to and fro to widen or narrow the space between its edge and the tip of the blade so as to control the amount of work to be done or material to be removed by the operation of the plane.

Having described our invention, what we claim as new and desire to secure by Letters Patent, is:

1. A plane having a throat-opening enlarged forwardly of the blade and bounded on the side by the side rails of the plane, the said rails having their lower edges notched on the inner face thereof from about the blade-tip to the forward end of the throat, and a plate slidably mounted on the fore-stock and between the rails and extended to and into the throat and thence bent to provide a bottom face level with the bottom face of the stock, the plate at said end having an edge extended to fit into the said notch in the side rails, substantially as described.

2. A plane having a forwardly extended throat and an adjusting plate adjustably mounted on the forestock and extending into the throat and of a width equal to the distance between the side rails at the top of the throat-opening but widening at the bottom of said opening to extend laterally beyond the inner faces of the side rails, the bottom edges of the side rails being cut out and partly therethrough to receive the said widened portion of the plate, substantially as shown.

In testimony whereof we affix our signatures in presence of two witnesses.

BURTON M. GRAVES.

FRANK N. LOSON.

Witnesses:

SAMUEL P. GURNSEY,

EMERSON GRAVES.