No. 108,946 – Improvement In Caps For Plane-Irons (Charles N. Tuttle) (1870)

United States Patent Office.

CHARLES N. TUTTLE, OF AUBURN, NEW YORK.

Letters Patent No. 108,946, dated November 1. 1870.

_________________

IMPROVEMENT IN CAPS FOR PLANE-IRONS.

_________________

The Schedule referred to in these Letters Patent and making part of the same.

_________________

I, CHARLES N. TUTTLE, of Auburn, Cayuga county, New York, have invented certain new and useful Improvements in Caps for Plane-Irons, of which the following is a specification.

Heretofore, in the manufacture of steel caps for plane-irons, it has been usual to forrn the raised hub that enters the elongated-slot of the cutter-iron, and that receives the confining and adjusting-screw, from the body of the cap itself, by swaging up such hub; but this is quite an expensive process, and necessitates the heating to a greater degree, and for a longer time, of the cap.

My object is to cheapen the construction of the cap and manufacture it by a simpler process; and

My invention consists in a cap having a metallic hub secured thereto by brazing, and which is afterward provided with a screw-thread, and thus forms an improved cap.

In the accompanying drawing —

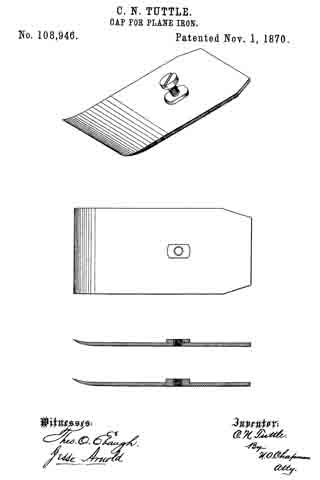

Figure 1 represents, in perspective, my improved cap;

Figure 2, a. top view;

Figure 3, longitudinal central section; and

Figure 4, a longitudinal central section of a modified form.

A represents the cap of a double plane-iron, which is to be formed of steel; but, instead of swaging up a hub on the surface of the cap, I am enabled to do entirely away with such action by simply cutting off from a strip of smooth iron of proper width and thickness a length suitable for a hub, B, and this I secure to the surtitce of the cap, which I am enabled to make irom the regular rolled steel or iron, by means of brazing.

It will be evident to those skilled in the manufacture of these articles that it is a great desideratum to be able to use the regular rolled steel or iron, and have simply to cut it off the proper length, turn the corners, and round up and sharpen the Iower edge, thus obviating the heating and working of but one end.

The cap and hub are provided with a hole either after or before brazing the hub to the cap, which is provided with a thread to receive a confining and adjusting-nut, C’, which I prefer to make of malleable iron on account of cheapness and durability.

Instead of brazing the hub directly to the surface of the cap, I may punch a hole of suitable size through the cap, and in this hole place a hub of at thickness necessary to fill up such opening, and also project the proper distance above the cap to form a hub, as in fig. 4, and this hub I brazed in or to the opening in the cap.

In all cases where a hub is formed or secured to the cap by swaging, the hub has afterward to be dressed square on the sides; but with a hub previously squared in its manufacture, and then brazed, this tedious and rather expensive portion of the manufacture is avoided.

Having described my invention, I claim —

The plane-iron cap, provided with a nut when each is formed in separate pieces, and brazed together, as and for the purpose herein specified.

C. N. TUTTLE.

Witnesses:

C. W. UPHAM,

C. N. TUTTLE, Jr.