No. 334,324 – Plane (John Woods) (1886)

No. 334,324 – Plane (John Woods) (1886)

UNITED STATES PATENT OFFICE.

_________________

JOHN WOODS, OF COLUMBIA, TENNESSEE.

PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 334,324, dated January 12, 1886.

Application filed May 16, 1885. Serial No. 165,739. (No model.)

_________________

To all whom it may concern:

Be it known that I, JOHN WOODS, a citizen of the United States, residing at Columbia, in the county of Maury and State of Tennessee, have invented certain new and useful Improvements in Planes, of which the following is a specification.

This invention relates to improvements in planes; and it consists in certain improved constructions and means for adjusting the knife or cutter-blade, whereby the proper adjustment may be made with facility and precision, all as will be hereinafter described, and particularly pointed out in the claim.

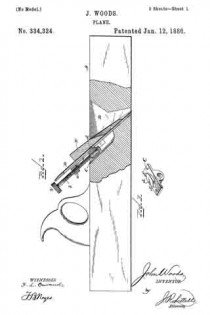

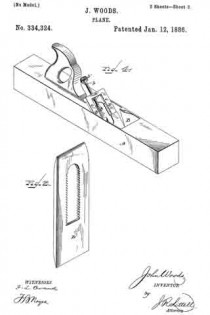

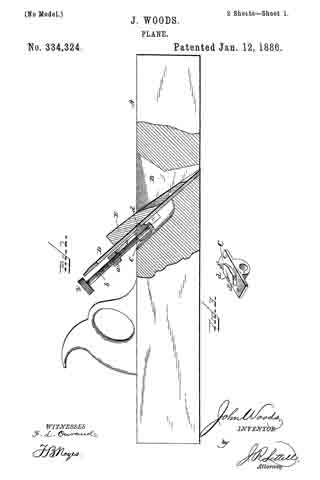

In the accompanying drawings, in the different figures of which corresponding parts are denoted by similar letters of reference, Figure 1 is a vertical longitudinal section of a common plane provided with my improvement; Fig. 2, a detail perspective of the cutter; Fig. 3, a detail perspective of the removable adjusting-block, and Fig. 4 a perspective of the plane with the wedge and knife removed.

The letter A designates the stock; B, the usual box. At the end of the box is secured a frame consisting of bars a and cross-bar a’, into which latter screws a long adjusting-screw, b, having a milled head, b’. To the lower end of this screw b is swiveled in any suitable manner the adjusting-block C, which has wings c extending over and sliding upon the side arms, a, of the frame. This adjusting-block also has a projection, d, formed with angular sides d’, which engage correspondingly-shaped notches or serrations in the sides of the longitudinal slot of the cutter D.

E is the usual wedge for firmly securing the cutter in place.

The operation of my adjusting device is as follows: The adjusting-screw, with its swiveled block C, being in place in the frame, the knife is put into the box so that two opposite serrations or notches will fit over the angular sides d’ of the projections d on said block, after which the wedge should be put in to loosely rest upon the blade. The blade is then elevated or lowered, by means of the screw b, until its cutting edge projects just the right distance beyond the sole of the plane, when the wedge may be driven down to further secure or clamp the blade from any movement in the box.

This construction of adjusting mechanism, it will be seen, is at once easily and quickly operated. As the blade becomes worn, the adjusting-block can be put into the next higher notches.

I do not limit myself to the exact configuration or number of notches and corresponding sides of the projections engaging them, or even to this particular means for securing the adjusting-block to the cutter or blade, as they may be obviously modified or changed and still come within the scope of my invention.

What I claim as my invention, and desire to secure by Letters Patent, is —

The frame mounted in the rear of the box of a plane, a screw passing through a cross-bar therein, and a swiveled block on the end of said screw, having a projection with angular sides to engage the slot in the cutter or knife, combined with a cutter or blade with its longitudinal slot provided with notches or serrations in its sides corresponding in outline to that of the angular sides of the projection, substantially as described.

In testimony whereof I affix my signature in presence of two witnesses.

JOHN VVOODS.

Witnesses:

Z. WATTS,

G. A. LANIER.