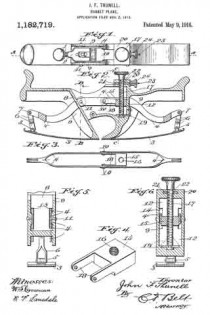

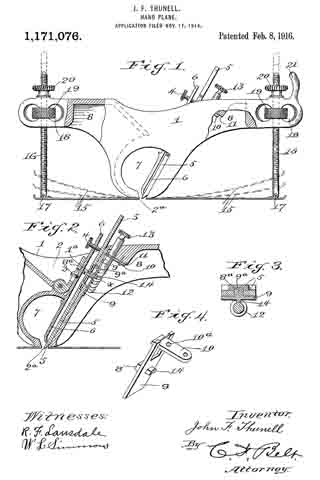

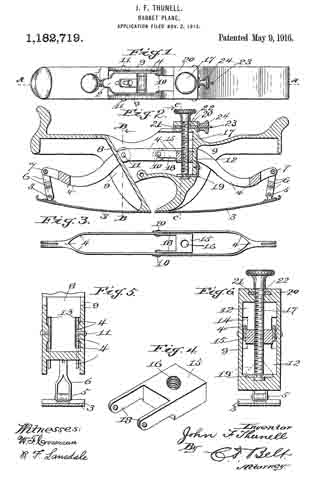

No. 1,182,719 – Rabbet-Plane (John F. Thunell) (1916)

UNITED STATES PATENT OFFICE.

_________________

JOHN F. THUNELL, OF SALT LAKE CITY, UTAH.

RABBET-PLANE.

_________________

1,182,719. Specification of Letters Patent. Patented May. 9, 1916.

Application filed November 2, 1915. Serial No. 59,178.

_________________

To all whom it may concern:

Be it known that I, JOHN F. THUNELL, a citizen of the United States, residing at Salt Lake City, in the county of Salt Lake and State of Utah, have invented certain new and useful Improvements in Rabbet-Planes, of which the following is a specification.

This invention relates to hand planes, and pertains especially to planes for cutting curved or circular rabbets of various forms and curvature, and having adjustable runners.

The object of the invention is to provide novel and peculiar means for adjusting a pair of plane runners equally and without variation between the runners in perfecting their uniform adjustment.

A further object of the invention is to provide mechanism connecting the free end of the runners of a rabbet plane and fulcrumed within the plane body whereby the runners may be given uniform adjustment, and to furnish novel and peculiar means for operating said mechanism to give the runners such uniform curvature as desired or as occasion may demand, without separate adjustment of the runners.

Various other objects, advantages and improved results are attainable in the practical application of the invention as hereinafter fully described.

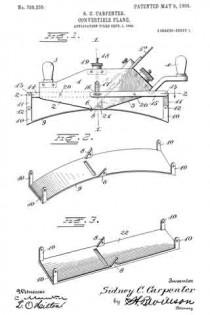

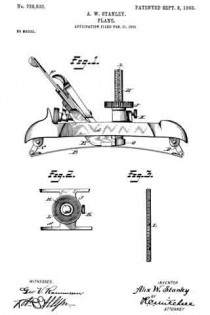

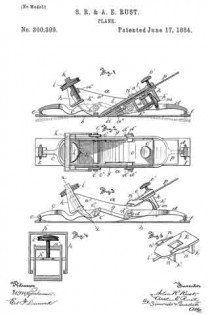

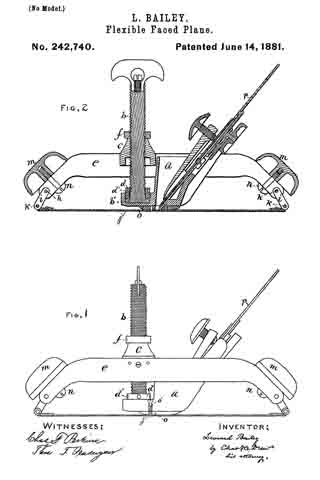

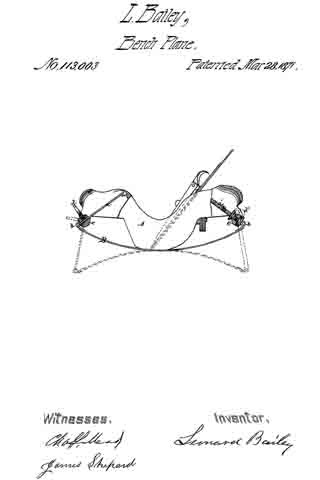

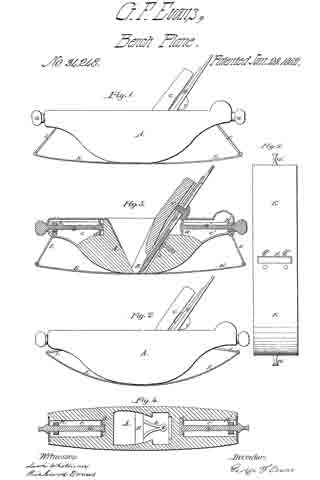

In the accompanying drawings forming part of this application :– Figure 1 is a top view of a rabbet plane embodying my invention. Fig. 2 is a sectional view taken on the plane indicated by the dotted line A–A Fig. 1, with the bit adjusting device removed. Fig. 3 is a detail plan view of the runner operating levers and follower block. Fig. 4 is a detail perspective view of the screw-locking device. Fig. 5 is an enlarged sectional view taken on the dotted line B–B Fig. 2. Fig. 6 is a similar view taken on the dotted line C–C Fig. 2.

The same reference characters denote the same parts throughout the several views of the drawings.

The means operated by the screw 1, for adjusting the bit 2, is covered by my application Ser. No. 872,608, allowed July 12, 1915, and therefore the same is not claimed in this application, and while the runners of this application are the same as those shown in said allowed application, the mechanism for operating the flexible runners 3, and the device for locking said mechanism to fix the runners in various positions constitute the subject of this application.

The runner operating mechanism comprises a pair of duplicate levers 4, pivotally connected at 5 with the movable end of the runners 3, by a forked hanger 6, pivoted at 7, to the outer end of the levers 4 where they are united in pairs. The levers 4 are branched laterally in pairs from their outer end and extend through the inclined throat wall 3 and adjacent to the side walls 9 of the throat. The pair of levers for one runner are pivoted to the pair of levers for the other runner by pivot pins 10, and the levers of one pair are pivoted at 11, to the throat walls 9, while the levers of the other pair are fulcrumed to and between the walls 9 and a vertical wall 12. One pair of the levers are operated through slots 13, in the wall 8, and the other pair of levers are operated through slots 14, in the wall 12. The device for operating the levers comprises a follower block 15 having a screw threaded aperture 16, for a screw 17, and a pair of arms 13 fulcrumed to the lever 4 by means of the lever pins 10. The screw 17 is anchored by means of a bracket 19 secured to and projecting inwardly from the wall 12, and said screw projects through a top wall 20 of the plane and is provided with a milled head for turning the screw in the anchor bracket, whereby the follower block 15 is moved vertically, and by such movement operates the levers 4 which carry the runners 3 to various curved positions as desired or as occasion may demand. The device for locking the screw and thereby fixing the levers and the runners in desired position for operating the plane, comprises a plate 21 slidably contained within the wall 20, and having an aperture 22 for the screw 17, and a screw stem 23 provided with a thumb nut 24 working against the outer face of the wall 20 for sliding the plate into and out of engagement with the screw. Obviously when the screw is locked the levers 4 and the runners are fixed in position for operating the plane.

It will be seen that the movement of the levers and runners is not only accomplished by operating the screw 17, but the screw and its locking device controls the levers and the runners so that the set position of the runners may be maintained during a planing operation. It will be further observed that the runner adjusting mechanism affords means for giving the runners minute curvatures, and that such curvature must be the same in both runners, under one and the same movement of the screw.

I do not wish to limit myself to any particular number of levers for operating the runners, to the size, material or shape of any of the parts of my invention, nor to the particular location of the pivot and fulcrum points of the runner operating levers, but reserve the right to make such changes and variations in the practical application of the invention as may come within the scope of the appended claims.

Having thus described my invention what I claim as new and desire to secure by Letters Patent is:–

1. In a plane, a pair of flexible runners having one end secured opposite the bit slot of the plane, a pair of fulcrumed levers pivotally connected with each runner, the levers of one runner being pivoted to the levers of the other runner, a vertically movable screw block having arms pivoted on the pivot of said levers, a vertical screw extending through the block for operating the levers, an anchor bracket attached to the outer side of the stock and holding the lower end of the screw, and a plate slidable at right angles to the screw for locking the screw.

2. The combination with flexible plane runners, runner levers pivoted together and to the walls of the plane stock, a follower screw block movable vertically between the levers of one pair and having arms pivoted to the connecting pivot of said levers, a vertically anchored screw working through the block for operating the levers, and a plate contained within the top of the stock and slidable in the path of movement of the screw for locking the screw.

3. In a device for operating flexible plane runners, two pairs of pivoted runner levers, pivots connecting the inner end of the levers, a follow screw block between the levers of one pair and having a pairof arms pivoted on said pivots, a vertically anchored screw working through the block for operating the levers, and a locking plate having a screw stem for sliding the plate into the path of movement of the screw.

In witness whereof I hereunto set my hand in the presence of two witnesses.

JOHN F. THUNELL.

Witnesses:

ISAAC P. THUNELL,

NEPHIN GLEDHILL.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________