No. 445,792 – Plane (Granville W. Wright) (1891)

UNITED STATES PATENT OFFICE.

_________________

GRANVILLE W. WRIGHT, OF NEW HAVEN, CONNECTICUT,

ASSIGNOR TO SARGENT & COMPANY, OF SAME PLACE.

PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 445,792, dated February 3, 1891.

Application filed October 6, 1890. Serial No. 367,225. (No model.)

_________________

To all whom it may concern:

Be it known that I, GRANVILLE W. WRIGHT, of New Haven, in the county of New Haven and State of Connecticut, have invented new Improvements in Planes; and I do hereby declare the following, when taken in connection with accompanying drawings and the letters of reference marked thereon, to be a full, clear, and exact description ot the same, and which said drawings constitute part of this specincation, and represent, in —

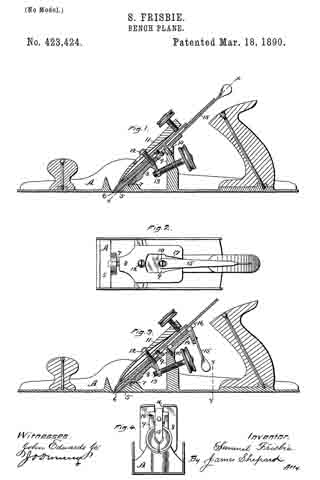

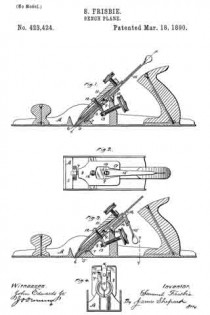

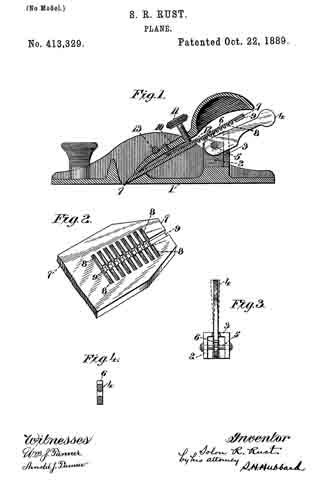

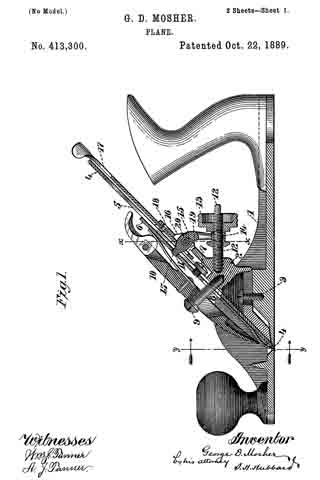

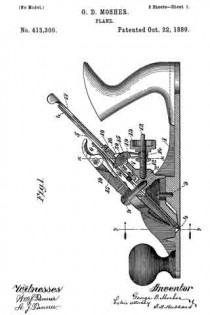

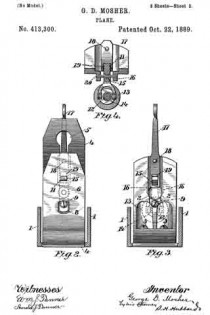

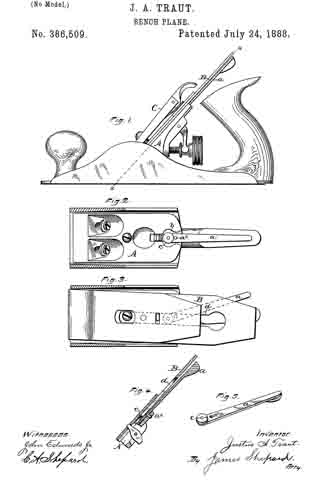

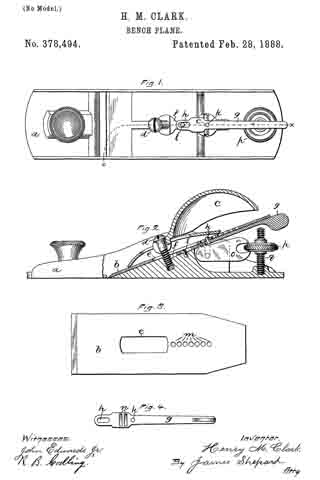

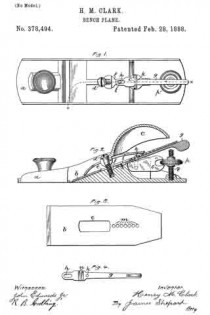

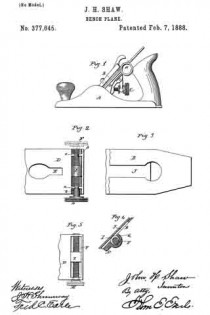

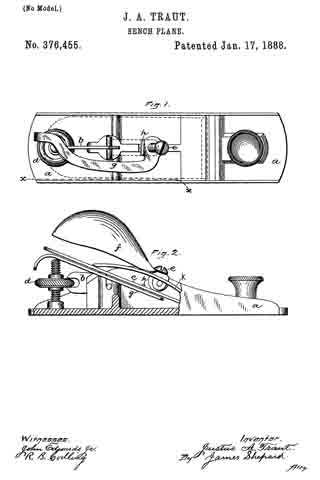

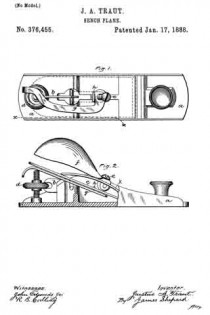

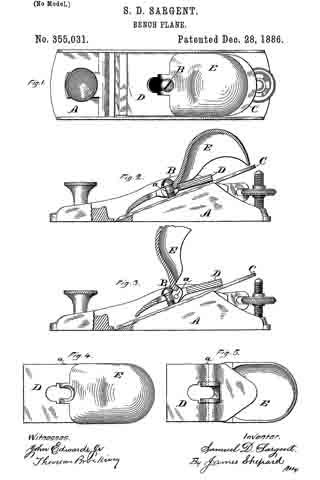

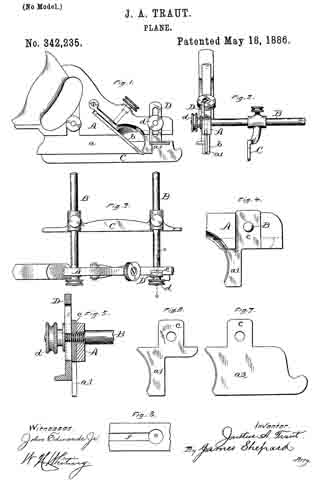

Figure 1, a side view with a portion of the plane-iron broken away to illustrate its connection with the adjusting-lever; Fig. 2, a top view with the plane-iron removed; Fig. 3, a face view of the plane-iron seat with the lever removed to show the transverse slot J and the slide therein.

This invention relates to an improvement in that class of planes in which the stock is made from metal, and in which provision is made for adjusting the upper end of the iron laterally, so as to change the angle of the iron with relation to the working-face of the stock, the invention relating particularly to the mechanism for producing such lateral adjustment; and it consists in the construction as hereinafter described, and particularly recited in the claim.

A represents the stock, which is made from cast-iron, and in which an inclined seat B is formed as a bed for the iron C, D representing the throat of the stock.

E represents the clamp by which the iron is held to its seat, all substantially as in the usual construction, and as here represented it is provided with an adjusting-screw F, by means of which the plane-iron may be raised or lowered to make the out less or more, as the case may be, also in the usual manner.

The particular mechanism as thus far described is too well known to require description.

The upper end of the seat B is recessed, and in the recess a lever G is hung upon a pivot H, and so as to swing in the plane of the seat B, on which the iron rests, this lever G lying directly back of the iron when in place, as seen in Fig. 1. Through the hub or body of this lever a segment-shaped slot I is formed eccentric to the pivot H, and as seen in Fig. Transversely across that portion of the bed in which the lever is hung is a slot J, (see Fig. 3,) in which a slide K is arranged, the said slide presenting a head L on the face adapted to stand in the vertical slot of the plane-iron, the width of the head being substantially the same as the width of the slot.

The said slide extends through the slot I of the lever G, and so that by turning the said lever G to the right or left the slide K will be moved transversely, according to the eccentricity of the slot I, and as indicated in broken lines, Fig. 2, and because the head L of the slide K stands in the slot of the plane-iron it necessarily follows that the upper end of the plane-iron is moved accordingly to the right or left, and such movement of the upper end of the plane-iron correspondingly turns the said iron to change its relation to the face of the plane, and so that the plane-iron may be adjusted to bring the line of its edge parallel with the face of the plane, or inclined thereto, as may be desired. The lever G preferably extends slightly above the upper edge of the plane-iron, so as to form a handle or thumb-piece, as M, by which it may be readily adjusted. When the plane-iron is secured to its seat and it is found necessary to change the line of the cutting-edge of the plane-iron with relation to the face of the plane, it is only necessary to turn the lever G to the right or left, as the adjustment may require, the clamp which secures the plane-iron to its seat being sufficient to hold it in place and yet permit such adjustment to be made, so that the adjustment may be made after the plane-iron has been firmly secured and without change of such securing devices.

From the foregoing it will be understood that I do not claim, broadly, a lever arranged in the stock back of the plane-iron as a means for adjusting the plane-iron transversely; but

What I do claim as my invention is —

In a plane substantially such as described, and in which the plane-iron is secured upon the seat in the stock, the stock constructed with a transverse slot above said seat and in rear of the plane-iron, a lever hung upon the stock in rear of the plane-iron and so as to swing in a plane parallel with the plane-iron and across said transverse slot, the lever constructed with a slot eccentric to the pivot on which it swings, and a, slide working in said transverse slot and extending through the said segmental slot of the lever into engagement with the plane-iron, substantially as and for the purpose described.

In testimony whereof I have signed this specification in the presence of two subscribing witnesses.

GRANVILLE W. WRIGHT.

Witnesses:

E. H. EGGLESTON,

W. S. COOKE.