No. 174,870 – Improvement In Carpenters’ Planes (Elliot G. Storke) (1876)

UNITED STATES PATENT OFFICE.

_________________

ELLIOT G. STORKE, OF AUBURN, NEW YORK.

IMPROVEMENT IN CARPENTERS’ PLANES.

_________________

Specification forming part of Letters Patent No. 174,870, dated March 14, 1876; application filed February 7, 1876.

_________________

To all whom it may concern:

Be it known that I, ELLIOT G. STORKE, of Auburn, in the State of New York, have invented certain new and useful Improvements in Carpenters’ Planes, of which the following is a specification:

The object of my invention is to provide a simple, easy, and exact method of adjusting the bits or cutters of carpenters’ planes.

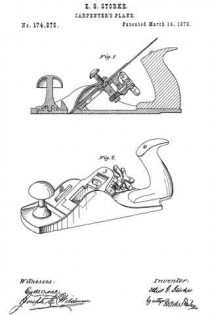

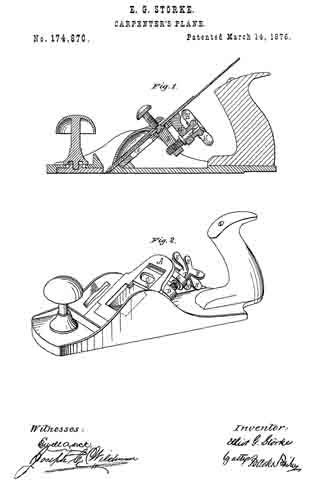

Figure 1 is a longitudinal vertical central section of an ordinary metallic plane embodying my improvements. Fig. 2 is a perspective view of the same with the bit removed.

Similar letters refer to the same parts in the respective figures.

A is the bed-plate for the support of the bit. Near the transverse center thereof is placed the sliding plate B, running in ways cut in the said bed-plate, having in its upper face an oval recess, C, for the reception of the cap screw heads of double plane-irons. From the lower face of the said sliding plate projects the shank-nut D, so far below the bed-plate that when the screw E is passed through its lower end, on a line parallel with the pitch of the plane-iron, a large thumb-wheel, F, can be mounted upon the upper end thereof without colliding with the plane-iron above or the plane-body below. That thumb-wheel is supplied with six arms, H, equally spaced upon its hub, giving as many distinct and conveniently-located levers, by which the workman can easily revolve the said wheel and move the parts with which it is connected. From the lower face of the bed-plate A, and near its upper end, projects the shank-bearing for the adjusting-screw G, of the same length as the shank-nut D, and in line therewith. Through the lower end of the said shank-bearing passes the upper end of the screw E into the hub of the said thumb-wheel, the former being shouldered where it joins the inner face of the latter, and the wheel, being pinned to the screw, carries the latter with it. Now, by revolving the thumb-wheel in the shank-bearing G, the shank-nut D and the sliding plate B are raised or lowered at pleasure, giving to the cutters a corresponding movement, and securing any desired thickness of shaving.

It will be seen from the foregoing description that my invention consists, mainly, in devices by which plane-bits are adjusted by a single direct-acting screw, operating through the medium of the cap-plates of double irons. The two shanks or lugs D and G, the screw E and sliding plate B, and the thumb-wheel F, with its arms H, are the devices employed for this purpose.

By projecting those lugs far below the bed-plate A — that is to say, far enough to carry the axis of the thumb-wheel to the center, or thereabout, of the space between the plane-iron and plane-body — I am enabled to use upon the screw E a large thumb-wheel supplied with the lever-arms H, and I thus gain all the power necessary to move the bits easily by the single screw E. The arms H, lying both to the right and left of the plane-handle, are easily and conveniently operated by the workman, either by the thumb from the left, or the fingers from the right, or both conjointly, without removing the hand — a device possessing decided conveniences over the circular thumb-screw heads heretofore in use for the same purpose.

I am aware that screws have been applied directly to plane-irons for their adjustment, but not in that way to the cap-plates of double irons, nor to their screw-heads. In the latter application the maximum movement of the operating-screw is less than one-half inch, in the former fully two and one-half inches, and a special attachment must be made to the cutter in which to work the screw; but that application, so far as I am informed, has been abandoned for the lack of power to operate the bits, and in its stead various combinations of single levers, or levers and cams operated by screws, have been resorted to, the objection to which is the increased cost of construction, and the greater liability to derangements and backlash.

I am also aware that various devices for adjusting plane-bits have been applied to the cap-plates or cap-screw heads of double plane-irons, but none, it is believed, in which that adjustment has been effected by a single screw without other intermediate devices.

The simplicity, durability, and practical efficiency of the devices herein described will, it is believed, be clearly apparent, as well as their superiority to those hitherto employed for the same purpose.

Having described my invention, I shall state my claim as follows:

The direct-acting or adjusting screw, having a thumb-wheel formed with lever-arms, as described, in combination with the bed-plate, having an elongated shank-bearing, and the sliding socket-plate, having an elongated shank-nut, all substantially as and for the purposes shown and set forth.

In testimony whereof I have hereunto signed my name this 3d day of February, A. D. 1876.

ELLIOT G. STORKE.

Witnesses:

H. L. STORKE,

LEWIS L. SMITH.