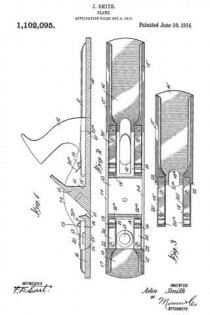

No. 1,102,095 – Plane (John Smith) (1914)

UNITED STATES PATENT OFFICE.

_________________

JOHN SMITH, OF POOLER, GEORGIA.

PLANE.

_________________

1,102,095. Specification of Letters Patent. Patented June 30, 1914.

Application filed October 9, 1913. Serial No. 794,225.

_________________

To all whom it may concern:

Be it known that I, JOHN SMITH, a citizen of the United States, and a resident of Pooler, in the county Of Chatham and State of Georgia, have invented a new and Improved Plane, of which the following is a full, clear, and exact description.

This invention relates to woodworking tools and has particular reference to the construction of carpenters’ planes whereby a tool of this character may be adjusted or modified in size and thereby made to serve as a substitute for several different sizes of planes commonly required by a carpenter.

The primary object of the invention, therefore, is to provide a tool of the class indicated which is adapted by the provision of one or more extensions to take the place of a set of planes including a smoothing or block plane, a jack plane, a fore-plane and a jointer.

The foregoing and other objects of the invention will hereinafter be more fully described and claimed and illustrated in the drawings forming a part of this specification in which like characters of reference indicate corresponding parts in all the views, and in which —

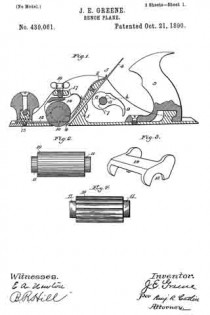

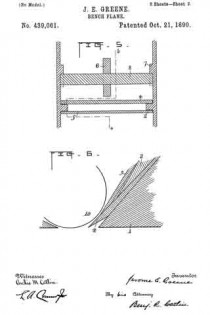

Figure 1 is a longitudinal section invention arranged as a jointer; Fig. 2 is a plan view of the same; and Fig. 3 is view of the rear extension detached.

The several parts of the device may be made of any suitable materials, and the relative sizes and proportions, as well as the general design of the mechanism, may be varied to a considerable extent without departing from the spirit of the invention hereinafter more fully set forth and specifically claimed.

A device made in accordance with this invention comprises a head or body 10 having a throat or mouth 11 for the accommodation of the usual bit and frog (not shown), and nsually provided also with a handle 12 and a knob 13, especially when made of metal. As is usual in the construction of metal planes there are provided vertical side flanges 14 extending from one end to the other of the body 10 and between which the supporting means 15 for the bit are arranged.

The body 10 to which the handle and knob are connected permanently constitutes what is commonly termed a block or smoothing plane, and in order to constitute such of the a plan implement into a jack plane an extension 16 is added to the front end thereof. Said extension 16 comprises a flat portion constituting an extension of the base of the body 10 and is provided on its lateral edges with reinforcement ribs 17 each having an arm 18 extending rearwardly in close engagement with the inner surface of the adjacent flange 14. Said arms span the joint between the main base and the extension and adjacent their rear ends I provide means to temporarily lock the extension to the front end of the body 10. As shown herein said locking means comprises a pair of studs 19 extending inwardly from the inner surfaces of the flanges 14 just above the rear ends of the arms 18. Preferably said arms are adapted to slip directly beneath and in close contact with said studs, as shown in Fig. 1. I also provide spring catches 20 which engage over the studs 19 and serve to prevent longitudinal displacement of the extension 16. The studs serve, therefore, directly to prevent the rear ends of the arms from tilting up and through the catchers 20 they prevent longitudinal movement, as above set forth. The principal strain, however, upon the extension would tend to be upward or in a direction to cause the front end of the extension to be elevated above the plane of the bottom of the implement. This tendency, however, is resisted effectively by means of a lip 21 extending into a rabbet 21′ formed across the end of the lower surface of the body 10. Said lip and rabbet are provided preferably with right angles and hence will not interfere with the aforesaid slidable movement of the extension when putting it in place. Lateral distortion or twisting of the parts is prevented by the fact that the arms have close engagement with the inner surfaces of the flanges 14 and also by the fact of the shoulders 22 cooperating with the ends of said flanges.

In order to constitute the implement into a jointer I provide a rearward extension 16′ preferably longer than the extension 16 but of the same general character, the same including a pair of arms 18′ each having a spring catch 20′ cooperating with a stud 19 in a manner similar to that above described. The ribs 17′ of this form of the invention reinforce and stiffen this member. This rearward extension 16′ also is provided with a lip or lips 21a extending forwardly on opposite sides of the base of the handle 12 into cooperation with the rabbet 21′, as shown in Fig. 1. The base of this extension is provided with a socket or notch 16a into which the base of the handle is snugly seated when the extension is shoved forwardly into place. Either of these extensions may be almost instantly attached or detached. The manner of detachment may consist in the holding of the body 10 in one hand and with the other hand spanning the handle or knob and causing two of the fingers of such hand to lift upon the free ends 20a of the catches. Such handle or knob constitutes therefore a fulcrum to assist in such lifting movement, and the pressure between the hand and the ends of the fingers causes sufficient outward or rearward movement of the extension to unlock the catches from the studs. The two parts, then, may be pulled apart directly without resistance. The assembling movement will be readily understood from what has been said above, and requires but a simple shove of the extension directly into its place, the ends 20a of the catches causing the catches to ride automatically over and into engagement with the studs.

Having thus described my invention, I claim as new and desire to secure by Letters Patent:–

1. In an implement of the class set forth the combination of a main plane body having a base and upwardly extending side flanges, an extension for said body comprising a base adapted to aline with the body base, said extension also including a pair of arms extending along the body base adjacent the inner surfaces of said flanges, a pair of studs secured to said iianges and extending toward each other in contact with the upper surfaces of said arms to prevent downward tilting of the extension, and means engaging over said studs to prevent longitudinal displacement of the extension.

2. In a plane, the combination with a main body including a base and a pair of upwardly extending lateral flanges, of an extension for either end of said base, said extension comprising a base adapted to aline with the aforesaid base and also including a pair of arms extending along the top of the main base just within the flanges thereof, a pair of studs cooperating directly with the upper surfaces of said arms, a pair of spring catches secured to the arms and adapted to snap automatically over said studs when the extension is shoved into place, and means cooperating with said arms to prevent the upward tilting of the extension.

3. In a plane, the combination of a main body including a base, vertical side flanges extending upwardly from the base, and a pair of studs extending inwardly from the inner faces of said side flanges in alinement with each other and spaced above the upper surface of said base, an extension for the main body including a base adapted to abut against the aforesaid body base, a pair of rigid arms extending from the extension and lying snugly between said studs and the main body base, and means on the arms cooperating with said arms and studs serving to prevent accidental removal of the extension from the base.

In testimony whereof I have signed my name to this specification in the presence of two subscribing witnesses.

JOHN SMITH.

Witnesses:

JOHN B. SMITH,

E. CARMEL MURPHY.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________