No. 794,667 – Plane (Gustav Dechant) (1905)

UNITED STATES PATENT OFFICE.

_________________

GUSTAV DECHANT, OF KIEL, GERMANY.

PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 794,667, dated July 11, 1905.

Application filed May 10, 1904. Serial No. 207,307.

_________________

To all whom it may concern:

Be it known that I, GUSTAV DECHANT, a subject of the German Emperor, and a resident of Gerhardtstrasse 5, Kiel, Germany, have invented certain new and useful Improvements in Planes, of which the following is a specification.

My invention relates to improvements in planes holding several adjustable blades or bits; and its object is to provide a plane which may be used successively for different kinds of work, such as chipping, planing, finishing, rabbeting, &c., thus uniting several tools in one.

I attain my object by the construction illustrated herewith on the accompanying drawings, in which —

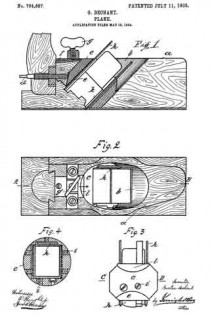

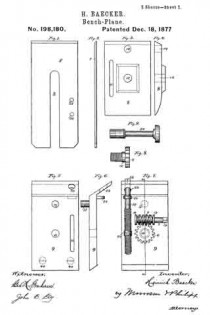

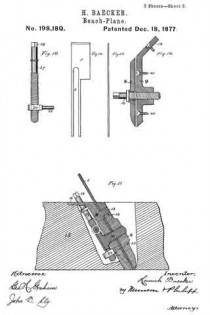

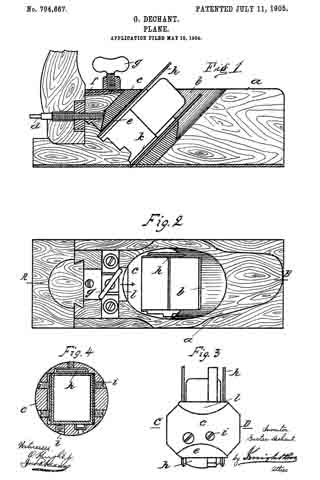

Figure 1 is a section on the line A B of Fig. 2; Fig. 2, a plan view of the same; Fig. 3, a front view of the casing for the blades hereinafter referred to; and Fig. 4, a section on the line C D of the said casing.

To the stock a of the plane there is secured in an oblique cylindrical aperture b a casing c, holding several blades or bits as they are used for several kinds of work, as above mentioned. The casing is adjustable in longitudinal direction by means of a set-screw d, pressing against the beveled surfaces e, and so adjustable that the said casing may be made sliding up or down. A leaf or small metal plate f is provided for securing the said casing in its position and preventing its disarrangement or untimely sliding upward, a small screw g pressing the said leaf against the casing. The blades or bits h, for the several kinds of work are provided within the said casing, which contains also a square tube k, against the surfaces of which the said blades are pressed and held fast by the small screws i.

In putting the plane to use I first give it the ordinary position which is for the coarsest work — the chipping. In order to use the tool for fmer or rabbeting work, I loosen the set-screw and turn the casing far enough to put the next blade or bit in position, and again the third and fourth. Marks l are provided to show how far the casing is to be turned each time to give it the position in which the several plates can be put to work. By turning on the screw each blade is kept fast, as aforesaid.

The above-mentioned square tube k may be substituted by any other suitable form, the number of blades depending on the number of surfaces of the said tube, so that each blade may be supported by a surface.

What I claim as my invention, and desire to protect by Letters Patent, is —

1. In a plane, the combination of the stock provided with an inclined cylindrical opening, a cylindrical casing having a beveled portion surrounding it, a plurality of tools carried by said casing, and a screw acting on the beveled portion of the cylindrical casing.

2. In a plane, the combination of a stock provided with a cylindrical oblique aperture, a casing with beveled surfaces, a square or other angular tube inserted in the said casing, several blades or bits contained in the said casing, each of the said blades or bits resting on a surface of the said angular tube, and screws for adjusting and holding fast the said casing and blades substantially as described.

In testimony whereof I have hereunto signed my name in the presence of two witnesses.

GUSTAV DECHANT.

Witnesses:

JULIUS RõPKE,

CARL FUHLJAHN.