No. 917,568 – Scraper (Andrew Ekman) (1909)

UNITED STATES PATENT OFFICE.

_________________

ANDREW EKMAN, OF GRAND RAPIDS, MICHIGAN.

SCRAPER.

_________________

917,568. Specification of Letters Patent. Patented April 6, 1909.

Application filed June 22, 1908. Serial No. 439,883.

_________________

To all whom it may concern:

Be it known that I, ANDREW EKMAN, a citizen of the United States, residing at Grand Rapids, in the county of Kent and State of Michigan, have invented certain new and useful Improvements in Scrapers, of which the following is a specification.

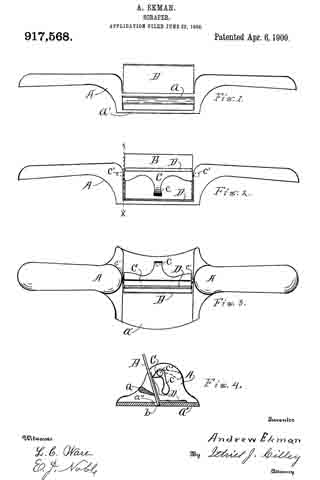

My invention relates to improvements in scrapers for use in scraping and smoothing the surface of lumber, as in the manufacture of furniture, inside finish, &c., and its objects are: first, to provide a means for readily and securely fastening the scraper bit to place in such a manner that there will be no possible chance for it to tremble when being worked upon the surface of lumber, and, second, to provide a means whereby the scraper bit may be readily clamped to place by the use of an eccentric cam without danger of draiving the bit up from the desired position. I attain these objects by the mechanism illustrated in the accompanying drawing, in which —

Figure 1 is a front elevation of the scraper. Fig. 2 is a back elevation of the same. Fig. 3 is a top plan of the same, and Fig. 4 is a transverse section of the same on the line x x of Fig. 2.

Similar letters refer to similar parts throughout the several views.

In the construction of this scraper I make use of a frame A, having handles projecting sidewise from the bit-holding portion of the frame, somewhat after the form of an ordinary spoke shave frame. The bottom, a’ of this frame is thin and broad and has a slot through its center, as at a” in Fig. 4, for the passage of the edge of the bit B, and an integral girth a arranged to bear equally across the entire length of the force of the bit a short distance above the bottom a’ so that with the bit in its proper position, as indicated in Fig. 4, the back of the lower edge of the bit will bear against the bottom a’ with the scraping edge b projecting just far enough below the bottom of the frame to engage the wood being scraped, to the desired depth. To secure the bit to place I provide an eccentric cam C, having a short lever c integral therewith, for actuating the cam to press its edge against the surface of the bit its entire length, thus forcing the upper edge of the bit forward so that its hotly will be forced against the girth a in such a manner that the back surface of the lower edge of the bit will bear heavily against the edge of the bottom a’, in the slot a”, the entire length of the bit, thus readily clamping the bit to place and holding it so securely the whole length that it will be impossible for any portion of the bit to tremble or “chatter” and render the surface being scraped, rough and uneven. This cam may be flattened at the point so that the pressure of the bit against it will hold it to place to retain the bit firmly in position.

I provide for averting the danger of drawing the bit upward with the cam C, by securing a thin metal plate D to the frame in such a manner that one lip thereof will extend upward between the point of the cam and the surface of the bit, so that the movement of the cam when clamping the bit to place will act upon the surface of the plate D, thus having no effect upon the bit to draw it upward. Without this, or some equivalent appliance, this tool would be inoperative, or practically so, for the reason that it would be almost impossible to hold the bit to the desired position while clamping it to place with the cam C. The cam C is pivotally supported in the frame A by means of a rod passing through it and forming short gudgeons projecting from each end, as at c’, into corresponding holes in the frame, as indicated in Figs. 2 and 3, and has a short lever c projecting down from its longitudinal center, with which to actuate it for securing or liberating the bit, as hereinbefore described and as shown in Figs. 2. 3, and 4.

It will be noticed that the bit B, in this tool, inclines to the front, instead of to the back as with planes &c., which position is bit the finished than the cutting designed for use necessary to give to the results of a scraper rather results of a plane, it being after the plane has reduced the surface to as near a finished surface as is possible with a plane, and before the application of sandpaper for a final finish.

I find that the most convenient, and in fact, the only really practical way to pivot the cam C into the frame is to drill a hole through the side of the frame and the length of the cam and pass a rod through of suflicient length to engage the frame at both ends of the cam, in which case the rod must be securely clamped into the cam to avert the danger of its sliding endwise and one end becoming disengaged from the frame. Another object to be carefully provided for is to so place the cam, and so finish its bearing edge, the bearing edge of the girth a and the bearing edge of the bottom plate a’ in the slot a” that the corresponding portions of the bit B will have perfect contact the entire length of the several bearing edges here mentioned. To release the bit B for removing it from the frame, it is only necessary to throw the handle c of the cam C up to the position indicated by the dotted lines in Fig. 4 when the plate D will be released and the bit may be readily removed or inserted.

What I claim as my invention, and desire to secure by Letters Patent, is:

In a furniture scraper, a supporting frame, a thin bottom thereto having a longitudinal slot through it, a girth connecting the sides of the trains above the bottom plate, in position so that a line from the bearing b on the bottom directly across the bearing face of the girth will incline sharply forwad, a bit extending up from the slot to and some distance above the girth, a protecting plate secured to the bottom of the frame and extending up along the surface of the bit, and a cam pivotally secured in the frame in position to bear against the protecting plate and force the bit solidly between the cam and the bearing b in the bottom of the frame on one side, and the girth on on the other side.

Signed at Grand Rapids Michigan June 19th, 1908.

ANDREW EKMAN.

In presence of —

T. M. NESBITT,

GEORGE L. KELNER.