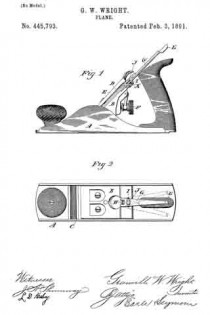

No. 512,084 – Bench-Plane (Granville W. Wright And Albert A. Page) (1894)

UNITED STATES PATENT OFFICE.

_________________

GRANVILLE W. WRIGHT AND ALBERT A. PAGE, OF NEW HAVEN, CONNECTICUT,

ASSIGNORS TO THE SARGENT & COMPANY, OF SAME PLACE.

BENCH-PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 512,084, dated January 2, 1894.

Application filed May 15, 1893. Serial No. 474,270. (No model.)

_________________

To all whom it may concern:

Be it known that we, GRANVILLE W. WRIGHT and ALBERT A. PAGE, of New Haven, in the county of New Haven and State of Connecticut, have invented a new Improvement in Bench-Planes; and we do hereby declare the following, when taken in connection with accompanying drawings and the letters of reference marked thereon, to be a full, clear, and exact description of the same, and which said drawings constitute part of this specification, and represent, in —

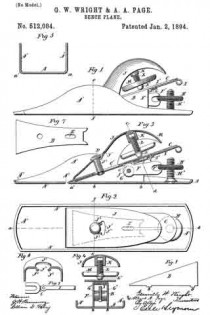

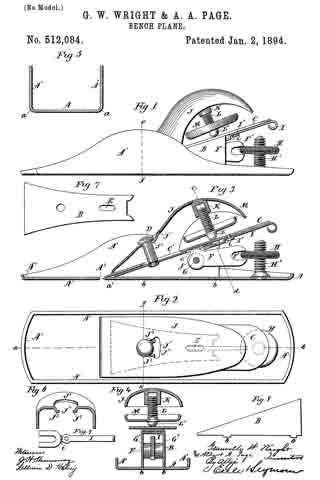

Figure 1, a view in side elevation of one form which a plane constructed in accordance with our invention may assume; Fig. 2, a plan view thereof; Fig. 3, a view thereof in central vertical longitudinal section on the line a–b of Fig. 2; Fig. 4, a view of the plane in transverse section on the line c–d of Fig. 3; Fig. 5, a view in transverse section through the stock of the plane on the line e–f of Fig. 1; Fig. 6, a detached view through the clamp of the plane on the line g–h of Fig. 2; Fig. 7, a detached plan view of the box or housing; Fig. 8, a similar view thereof in side elevation; Fig. 9, a detached reverse plan view of the secondary adjusting lever.

Our invention relates to an improvement in bench-planes, the object being to produce at a low cost for manufacture, a simple, light, durable and convenient article.

With these ends in view, our invention consists in a bench-plane having certain details of construction as will be hereinafter described and pointed out in the claims.

In carrying out our invention we form a stock A, from a single piece of heavy sheet-metal, which is struck into the required shape, the stock having the usual side flanges A’, and in addition thereto upturned end flanges A2 A2, into which the side flanges merge, as clearly shown by Figs. 1, 2 and 3 of the drawings. The stock thus formed will naturally have rounded side and end corners a, as shown in Figs. 4 and 5 of the drawings, that being an advantageous form, as such corners are less liable to mark or mar the article being planed than the sharp corners of planes having their stocks cast. The said stock is constructed with a transverse slot A3, located in the usual place, its rear wall of being beveled, as shown by Fig. 3 of the drawings.

Within the stock we locate a box or housing B, which we preferably strike up from a single piece of sheet-metal. This box may be said to be U-shaped in transverse section, and is arranged with its open side downward, as shown in Fig. 4 of the drawings, its edges being furnished with projecting lugs b b, by means of which it is secured to the stock A, the bottom of which is thereto provided with openings of suitable form to receive the said lugs. The box tapers gradually from its rear to its forward end, so as to form an inclined bed for the bit C, of the plane to rest upon. It also tapers laterally, growing wider from its rear to its forward end, so that it will form a wide bearing for the bit behind the cutting edge thereof. The vertical taper of the box is clearly shown by Fig. 8 of the drawings, while its lateral taper is seen in Fig. 7 of the same.

About midway the length of its inclined upper face or bed, the box is provided with a coupling-stud D, which stands at a right angle to the said bed. At its rear end the box is constructed with an elongated slot E, through which the teeth f of the primary adjusting-lever F, project, the said lever being hung upon a horizontal pin G, the ends of which are mounted in the sides of the box. Two thick washers G’ G’ located upon the said pin G, on opposite sides of the said lever F, prevent the same from lateral displacement on the pin. The outer end of the said lever is provided with an open longitudinal slot F’, which receives the knurled edge of an adjusting-nut H, mounted upon a threaded stud H’, secured in a vertical position to the rear end of the stock A. We do not, however, claim the said lever, nut or stud as new, for corresponding parts have been before employed for the same purpose in bench-planes. We have called the lever in question the primary adjusting lever because its function is to move the bit longitudinally to project its cutting edge from or withdraw it into the slot A3 for securing more or less depth of cut as required. The bit C is constructed upon its under face with a series of transverse grooves c, which are taken into by the teeth of the primary adjusting lever F, and which are located in the rear of its longitudinal slot C’, with which it is provided to adapt it to fit over the coupling-stud D, and be longitudinally adjusted. A secondary adjusting-lever I, projecting at its rear end slightly beyond the rear end of the bit, is pivotally attached to the lower face thereof by means of a screw I’, the forward end of the said lever being offset as at i, and then extended forward, whereby it is adapted to enter the open rear end of the box or housing B, with the side walls of which its forward edges engage to secure a purchase for the lateral adjustment of the bit, which it shifts to keep square with respect to the position of its cutting edge in the transverse slot A3 in the stock. The offsetting of this secondary lever in order to enable it to enter the rear end of the housing, will be proportional to the thickness of the metal from which the housing is formed.

We do not broadly claim a bit having a secondary adjusting lever secured to its lower face as described, except when its forward end is offset downward to adapt it to enter last the housing. We have called the lever described the secondary adjusting lever, because its function of laterally adjusting bit for squaring its edge in the slot in the the body of the stock seems secondary to the longitudinal adjustment of the bit.

The clamp J, of our improved plane, we prefer to strike from a single piece of sheet-metal in substantially the form which clamps of bench-planes ordinarily have, except as will be specified. Toward its forward end the clamp is constructed with an opening J’ , adapted in size to pass the head of the coupling-stud D, and with an open slot J2, leading forward from the said opening, and narrower than the same, the said slot being flanked on each side by horizontal flanges J3 J3, which form bearings for the head of the said stud. Under this construction the clamp is adjusted over the coupling-stud upon the bit, and then drawn rearward for locking it in place, and the more it is pushed rearward after it is in place, the tighter it will clamp the bit. This is an obviously advantageous construction, for when the plane is used, the tendency will be for the bit to be pushed rearward, and thus to only more firmly lock the clamp in place. In planes as ordinarily constructed, the operation of the clamp is just the reverse of this. The clamp is provided in its rear end with an internally threaded socket K, which receives an adjusting-screw L, which is staked, or otherwise secured into a sheet-metal hand-wheel M. The head L’ of the screw projects below the outer face of the wheel in position to be engaged with the upper face of the bit to the rear of the slot C’ therein, in the ordinary manner.

In our improved plane as herein described, the stock, the housing or box located therein to form a bed for the bit, the clamp, and the hand-wheel are struck from sheet-metal. We would have it understood, however, that we do not limit ourselves to using the said parts in combination, but we may use any one of them, or any combination of them. By constructing the said parts of sheet-metal, we secure lightness and rigidity, and an increase of room within a plane of given size. We are also enabled to give the plane pleasing lines, and to produce it at a comparatively low cost for manufacture, and obviously the sheet-metal enables it to be given at a comparatively small expense, a very high finish. Nor do we limit ourselves to the particular construction and arrangement of parts shown and described, for the devices represented for adjusting the bit both longitudinally and laterally, may be replaced by other devices.

We would therefore have it understood that we do not limit ourselves to the construction herein shown, but hold ourselves at liberty to make such variations therefrom as fairly fall within the spirit and scope of our invention. We are aware, however, that we are not the first to utilize sheet-metal in the construction of bench-planes, a plane having a wooden stock reinforced by a wrought metal covering being old.

Having fully described our invention, what we claim as new, and desire to secure by Letters Patent, is —

1. A bench-plane having its clamp struck out from a single piece of sheet-metal, and provided within its rear end with an internally threaded socket, which receives the adjusting screw carrying the hand-wheel, and constructed at its forward end with an opening, and with an open slot leading forward from the said opening and narrower than the same, the said slot being flanked on either side by flanges set inward from the face of the clamp, substantially as described.

2. A bench-plane having its clamp constructed with an opening to receive the coupling-stud of the plane, and with an open slot narrower than the said opening, extending forward therefrom and flanked on each side by horizontal flanges set down below the face of the clamp, substantially as described.

3. A bench-plane having a sheet-metal stock, having up-turned side and end flanges, a sheet-metal box or housing secured thereto with its open side downward, by means of lugs formed upon its lower edges, inclining and widening fromits rear to its forward end and forming an inclined bed for the bit, a bit and a wide bearing just back of the cutting edge thereof, a sheet-metal clamp, a clamping-screw carried thereby, and means for adjusting the bit longitudinally and laterally, substantially as described.

In testimony whereof we have signed this specification in the presence of two subscribing witnesses.

GRANVILLE W. WRIGHT.

ALBERT A. PAGE.

Witnesses:

ROBERT MACARTHUR, Jr.,

JOHN B. FREYSINGER, Jr.