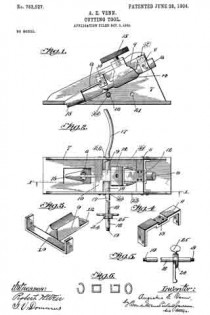

No. 763,527 – Cutting-Tool (Augustus E. Venn) (1904)

UNITED STATES PATENT OFFICE.

_________________

AUGUSTUS E. VENN, OF CHICAGO, ILLINOIS.

CUTTING-TOOL.

_________________

SPECIFICATION forming part of Letters Patent No. 763,527, dated June 28, 1904.

Application filed October 5, 1903. Serial No. 175,902. (No model.)

_________________

To all whom it may concern:

Be it known that I, AUGUSTUS E. VENN, a citizen of the United States, residing at Chicago, in the county of Cook and State of Illinois,have invented certain new and useful Improvements in Cutting-Tools, of which the following is a specification, reference being had to the accompanying drawings.

My invention relates to cutting-tools, and particularly to tools adapted to cut grooves in wood or other material to be operated upon; and its object is to provide a new and improved means by which, by the rotation of the cutter in the tool, grooves of different shapes may be cut in the work.

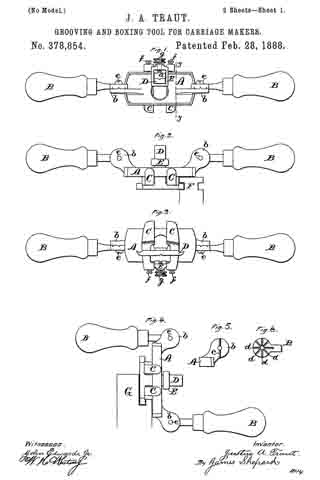

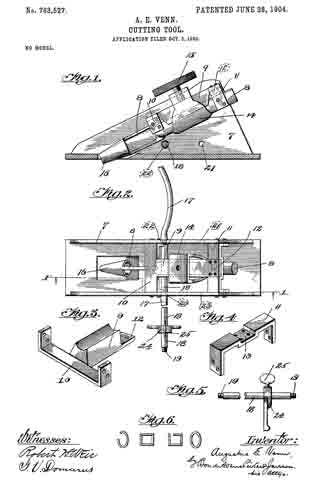

In the drawings, Figure 1 is a longitudinal vertical section on line 1 1 of Fig. 2. Fig. 2 is a top or plan view with one of the handles broken away. Fig. 3 is an enlarged detail, being an isometric view of a part of the support by means of which the cutter is secured to the stock. Fig. 4 is an enlarged detail, being an isometric view of a cross-bar by which one end of the support shown in Fig. 3 is secured to the stock. Fig. 5 is a detail, being a view of the gage, partly broken away; and Fig. 6 is a diagrammatic view showing several shapes which may be given to the cutting edge of the cutter.

As shown in the drawings and as preferably constructed, my invention is embodied in the form of a grooving-plane.

7 indicates the stock, and 8 the bit or cutter.

9 indicates a support which is provided with a cross-piece 10, preferably integral therewith, having its two ends bent up at right angles, as is best shown in Fig. 3, and of such length as to fit closely between the sides of the stock 7. The under side of the support 9 is rounded out, as is best shown in Fig. 3, to conform to the shape of the handle of the bit or cutter 8.

11 indicates a cross-piece which is bent at right angles at its ends and is of such length that the bent-up ends may fit snugly between the sides of the stock 7.

The support 9 is provided at the opposite end from the cross-piece 10 with a projection 12, and the cross-piece 11 is provided with a recessed portion 13 on its upper side, into which the projection 12 will snugly fit.

14 indicates a stirrup which is adapted to surround the rounded portion of the bit or cutter 8 and to pass around the support 9. It is provided on its upper surface with a screw-threaded opening into which a thumb-screw 15 may be screwed.

The bent ends of the cross-piece 10 and of the cross-piece 11 are provided with suitable screw-threaded openings by means of which they may be secured between the sides of the stock. The projection 12 of the support 9 is provided with screw-threaded openings and the recessed portion of the cross-piece 11 with corresponding openings, through which screws may pass to engage the screw-threaded openings in the projection 12 for the purpose of fastening the parts together.

The support 9 is placed between the sides of the stock with its hollowed rounded surface facing downward and is secured to the stock by suitable screws passing through the sides of the stock and into the screw-threaded openings in the bent ends of the cross-piece 10. The stirrup 14 is then placed in position around the support 9, the cross-piece 11 placed in position and fastened by screws to the sides of the stock, and the projection 12 is secured in place in the recess 13 by means of suitable screws.

The bit 8 is cylindrical at its upper end and is provided at its lower end with a cutting portion 16. The bit is provided with a proper clearance above the cutting portion, through which the shavings may pass, as is best shown in Fig. 2.

The cutting edge of the tool may be of various shapes, of which several are illustrated in Fig. 6. The cutter, being placed in position between the support 9 and the stirrup 14, may be adjusted longitudinally of itself, so that a proper amount of the cutting edge may project below the sole of the stock 7 through the usual opening therein, and is locked in position by turning the thumb-screw 15, which will cause the stirrup 14 to move up toward the support 9, firmly binding the cylindrical portion of the cutter between the stirrup and the support. It will be obvious that by rotating the cutter 8 upon its longitudinal axis, which it is obvious can be accomplished by loosening the set-screw 15 and then screwing it home when the desired amount of rotation is made, a different-shaped cutting edge will project below the sole of the stock 7 and a different-shaped groove thereby cut in the work.

17 (see Fig. 2) indicates handles, of which one is cut away upon one side to show the gage hereinafter described. The handles are secured to the stock in any appropriate way.

18 indicates a pin which is cylindrical in shape and has upon its ends screw-threaded portions 19. The sides of the stock 7 are provided with cylindrical openings 20 21, through which the cylindrical pin 18 may pass, and opposite the openings 20 21 are screw-threaded openings 22 23, which are adapted to engage with the screw-threaded ends of the pin.

24 indicates a gage which is provided with a suitable opening through which the pin 18 passes and which is secured in any desired position upon the pin 18 by means of a set-screw 25. It will be obvious that by this construction the gage can be used upon either side of the tool.

That which I claim as my invention, and desire to secure by Letters Patent, is —

1. The combination with a support, of a bit-iron mounted in said support adjustable longitudinally of itself therein and adapted to be rotated on its longitudinal axis and by its rotation to present a different-shaped cutting edge to the work, and means for locking said bit-iron in any desired position, substantially as described.

2. The combination with a plane-stock, of a bit-iron mounted in said stock adjustable longitudinally of itself therein and adapted to project its cutting edge below the sole of said stock, said bit-iron being rotatable on its longitudinal axis and having a cutting edge of such shape that by said rotation of said bit-iron grooves of different shape may be cut, and means for locking said bit-iron in any desired position, substantially as described.

3. The combination with a support of a cutting-tool adjustably mounted in said support adapted to be rotated on its longitudinal axis and having a tubular end provided with a cutting edge adapted by the rotation of said cutting-tool to present a different-shaped cutting edge tothe work, and means for locking said cutting-tool in any desired position, substantially as described.

4. The combination with a stock, a support secured to said stock, a stirrup surrounding said support, a set-screw carried by said stirrup adapted to bear upon one side of said support, a cutter having a shank adapted to be engaged between said support and said stirrup, said cutter being adapted to be rotated upon its longitudinal axis and having a cutting edge of such shape that by the rotation of said cutter grooves of different shape may be cut, substantially as described.

AUGUSTUS E. VENN.

Witnesses:

MINNIE A. HUNTER,

HELEN M. COLLIN.