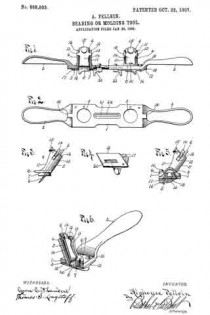

No. 868,803 – Beading Or Molding Tool (Alphonse Pellrin) (1907)

UNITED STATES PATENT OFFICE.

_________________

ALPHONSE PELLRIN, OF DETROIT, MICHIGAN.

BEADING OR MOLDING TOOL.

_________________

868,803. Specification of Letters Patent. Patented Oct. 22, 1907.

Application filed January 28, 1905. Serial No. 243,162.

_________________

To all whom it may concern:

Be it known that I, ALPHONSE PELLRIN, a citizen of the United States of America, residing at Detroit, in the county of Wayne and State of Michigan, have invented certain new and useful Improvements in Beading or Molding Tools, of which the following is a specification, reference being had therein to the accompanying drawings.

This invention relates to improvements in beading or molding tools, and its object is to provide a simple, cheap and efficient device so constructed that the cutting bit or blade may be rotated or turned to advance one end of the lower or cutting edge ot the bit along the line of its travel to give the same a shearing cut, and also to provide simple means for adjustably holding the bit which may be readily attached or detached.

A further object of the invention is to provide the same with a detachable sole plate and with certain other new and useful features, all as hereinafter more fully described, reference being had to the accompanying drawings, in which

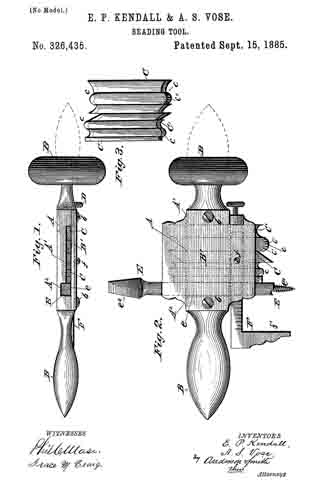

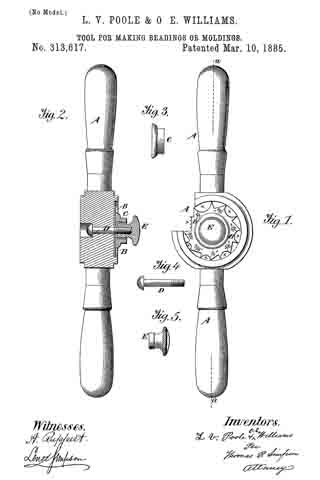

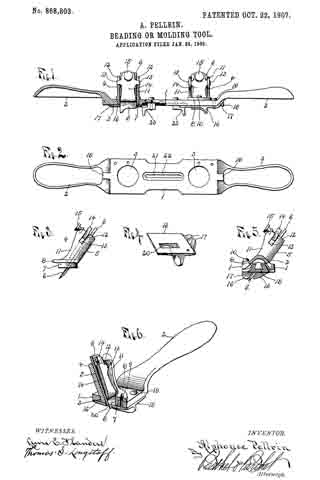

Figure 1, is a front edge elevation of a device embodying the invention and showing the same partly in longitudinal section; Fig. 2, is an inverted plan view ot the stock with all detachable parts removed; Fig. 3, is a side elevation of one of the knife or bit holders, detached; Fig. 4, is a perspective view of one of the sole plates, detached; Fig. 5, is an end view of the device with the handle broken away; and Fig. 6, is an enlarged perspective view of one end of the device showing the same in transverse section through the center of one ol the bit holders.

As shown in the drawing 1 is the stock of the tool consisting of a flat bar which is formed with a handle 2 at each end and with two circular openings 3, one near each end of the flat bar or stock, to receive the bit holders 4, each consisting of a casting formed with an upwardly extending inclined bed 5 for the knife or bit 6, and with a downwardly extending ring-shaped flange 7 to fit the circular opening 3 in the stock. The ring 7 is provided with an outwardly extending circular flange 8 to engage the upper surface of the stock and the holder is adjustably secured in the opening by providing an elongated slot 9 in said flange 8 to receive a screw 10 extending throughout and engaging a screw-threaded opening in the stock. Extending forward from the bed 5 at each side of the bit is the side flange 11, each of which is provided with a notch 12 extending downward from its upper end to receive laterally extending arms 13 on the clamping plate 14 which is provided with a screw-threaded opening near its upper end to receive a clamping thumb screw 15 adapted to extend through said opening and engage the bit, thus rocking said plate on its arms and causing the lower end thereof to press upon the bit and clamp the same firmly to its bed.

The lower end or cutting edge ot the bit 6 is shaped to give the article worked upon the desired form and a sole or wear plate 16 formed on its lower face to conform to the configuration of said cutting edge, is secured to the under surface of the stock over each opening 3 by providing said plate 16 with upwardly extending lugs 17 at one end, forming a dovetail opening between them to receive a dovetail rib 18 on the adjacent end of the stock, beneath the handle, and to further secure each sole plate in place, a screw 19 is provided. An opening 20 in said sole plate is provided for the end of the bit, through which it extends and which is of a size to permit the shavings to pass.

A longitudinal slot 21 is formed in the stock between the openings 3 and the lower face of the stock is cut away adjacent to said slot to term a longitudinal groove 22 to receive the stops 23 adapted to be adjusted along said groove and held therein by screws extending through the slot. These stops are provided to engage the edge of the board or other article being grooved or formed and cause the groove to be formed at the desired distance from the edge thereof.

For convenience the tool is provided with two bits or cutters but it is obvious that only one may be employed and by the particular construction of clamping plate but one screw is necessary and the plate and bit may be quickly removed by simply loosening the thumb screw.

By loosening the screws 10, the holders 4 may be turned within the openings 3 to set the blades or bits at an angle to the longitudinal axis of the stock or bar 1, so that one end of the cutting edge of each will cut in advance of the other end thereof and thus have a shearing action and so that the ends of said cutting edges may be moved nearer or farther from each other, thereby permitting line adjustment of the distance between the outer lines of the cut to be made.

Having thus fully described the invention what I claim is:

1. A routing tool comprising a stock adapted to be moved laterally across the work, a pair of bit holders each secured near one end of the stock, rotatable on an axis vertical to the plane of the stock, and each provided with a bit throat, a bit bed, a bit clamping plate and a bit having a cutting edge whose outer end projects beyond the body of the edge, so disposed that limited relative adjustment of the stock is obtained by the rotation of the bit holders, a guide slot between the bit holders in their axial plane, a gage plate for each bit holder adjustably secured in the slot, and a sole platefor each bit detachably interlocked with the stock outside of each bit holder, extending over and in register with the throat of the holder.

2. A routing tool comprising a narrow, substantially rectangular stock, adapted to be laterally moved across the work, handles on each end of the stock, integral therewith, a pair of bit holders, each consisting of a cylindrical base rotatably secured near one end of the stock vertically to the face of the stock, with its lower face flush with the stock face, means for clamping the holders in any desired angular relation to the stock, comprising a peripheral flange on the base, bearing on the upper side of the stock, a segmental slot in the flange, and a stud screw clamping the flange to the stock, passing through said slot, oblique means for securing a bit in each holder consisting of a bit bed extending obliquely up from the base, marginal, longitudinal flanges on the bed, longitudinally disposed grooves in the upper end portions of the flanges, a bit clamping plate provided with integral, alined lateral lugs between its ends, rocking and sliding in said grooves, and a thumb screw in the upper part of the clamping plate above the lugs, substantially perpendicular to the bed, means for centering the bit holders in relation to a neutral zone, consisting of a longitudinal slot in the stock between the bit holders in axial alinement therewith, whose margins in the stock bed are rabbeted to form a guide, gage plates for the bit holders, each provided with a longitudinal rib engaging the guide, adapted to center the bits in relation to a neutral surface between them, means for shielding bits in the holder comprising soles for each bit holder, each comprising a plate having an opening whose margins register substantially with the working edge of a bit, detachably held in alinement with a bit holder by a rib integrally fortned on the underside of the adjacent handle shank, adapted to dovetail with a lug integral with the plate, and a screw clamping the plate to the stock face over the bit holder.

3. A routing tool comprising a stock having a rectangular plane bed, handles integrally formed at each end thereof, a pair of bit holders in parallel spaced relation, each comprising a cylinder whose axis is perpendicular to the stock bed, each rotatably secured in an aperture in the bed near one end thereof, with their lower end faces flush with the bed, an annular flange on the upper end of each cylinder bearing on the upper side of the stock, a segmental slot in each flange, a screw passing through the slot, secured in the bed, a diametrically disposed throat opening in each cylinder, a lug extending obliquely from each cylinder, whose upper face is longitudinally grooved for a bit bed, a bit clamping plate, tiltably secured over each bed by integral, lateral lugs between the ends of the plate, sliding and rocking in parallel, longitudinal grooves in the side faces of the bed groove, a clamping thumb screw for each plate engaging a screw-threaded aperture in the upper end beyond the lugs, longitudinal, alined, undercut ribs on the under sides of the handle shanks, a shoe for each bit holder, provided with a lug adapted to detachably engage the adjacent undercut rib, and a countersunk screw engaging the stock, a longitudinal, rabbeted slot between the holders in their axial plane, an angle gage plate for each bit holder engaging said rabbeted slot, and a screw clamping each gage plate.

4. A routing tool comprising a stock, draw handles integrally formed at each end thereof, a bit holder rotatably secured at its lower end in the stock, axially perpendicular thereto, whose lower face is flush with the face of the stock, and is diametrically slotted to form a throat, a bit bed extending obliquely upward from the throat, parallel, longitudinal flanges on the sides of the bed integral with the holder, parallel slots in the upper parts of the flanges, a bit clamping plate provided with lateral alined lugs between its ends adapted to slide and rock in said grooves, a thumb-screw in the upper end of the plate transverse to the bed, a sole plate adapted to shield the projecting portion of the bit below the stock, a lug integral with the sole, detachably dovetailed to a rib integral with one of the handle-shanks beyond the end of the bed, a longitudinal guide slot in the bed between the bit holder and the other handle, and an adjustable gage for the bit longitudinally movable in said guide slot.

In testimony whereof I aflix my signature in presence of two witnesses.

ALPHONSE PELLRIN.

Witnesses:

OTTO F. BARTHEL,

THOMAS G. LONGSTAFF.