No. 305,603 – Cabinet-Scraper (John A. Keiser) (1884)

UNITED STATES PATENT OFFICE.

_________________

JOHN A. KEISER, OF CINCINNATI, OHIO.

CABINET-SCRAPER.

_________________

SPECIFICATION forming part of Letters Patent No. 305,603, dated September 23, 1884.

Application filed June 30, 1884. (No model.)

_________________

To all whom it may concern:

Be it known that I, JOHN A. KEISER, a citizen of the United States,and resident of Cincinnati, in the county of Hamilton and State of Ohio, have invented certain new and useful Improvements in Cabinet-Scrapers, of which the following is a specification, reference being had to the accompanying drawings forming a part hereof.

My invention relates to an improved cabinet-scraper.

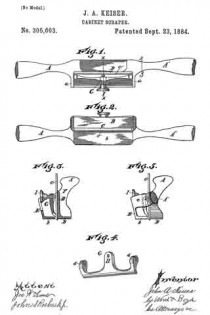

Figure 1 is a top plan view of my improvement. Fig. 2 is a bottom plan view of the same; Fig. 3, a section on line x x, Fig. 1; Fig. 4, a perspective view of the pivoted clamp; Fig. 5, a section on line z z, Fig. 1.

A A’ represent the handle of the scraper. The stock of the tool is composed of the following parts.

B b represent the face of the scraper; C, a slot separating the faces in which the cutter is set.

D represents a ledge, against which the cutter c is clamped. This ledge is rigidly attached to the face B, the parts forming an L, as shown in Fig. 3. F represents the ends of the stock, from which the handles A A’ spring, as shown in Figs. 1 and 2.

E e represent arms forming a part of the end plates of the stock F, for firmly holding face b rigidly in a plane parallel with face B.

G represents a pivotal clamp for clamping the knife c against the ledge D. This clamp is suspended on pivots a to the end plates ofthe stock F, passing through ears d of the clamp G.

H represents a lever-arm extending upward a considerable distance above the pivots of ears d.

I represents a set-screw tapping through the arms H, the point of which bears against the ledge D and forces the lower edge of clamp G against the cutter c at its lower end, and firnily clamps it against D.

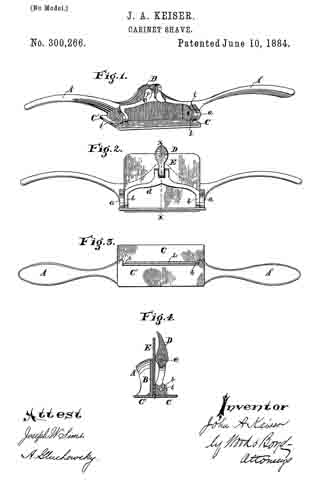

This tool is very cheap, strong, and efficient. The cutter c works clear to the ends of face B b, and is a decided improvement over the tool shown in Letters Patent granted Samuel C. Tatum & Co., my assignees, June 10, 1884, No. 300,266, and other tools for the same purpose hitherto used.

Instead of screw I, a cam may be used to operate the clamp, and would be the equivalent therefor.

I do not broadly claim a stock having rigid faces separated by a slot, and the front face strengthened by arms forming part of the ends of the stock; nor do I claim, broadly, a cutting-bit attached to an oscillating plate adjustable by a thumb-screw and spring; nor a spokeshave having a bearing-surface in front of the cutter applied by a lever having an adjusting-screw for regulating the width of the month, the thickness of its cut, or the shaving; and I do not broadly claim the bearing-surface of a stock provided with a ledge or flange serving as a bearing for the cutting-bit.

I claim —

1. A cabinet-shave consisting of the stock F, rigid faces B b, separated by slot C, the part b being braced by arms E e, forming part of the end plates of the stock, ledge D, and cutter c, clamped against the ledge, substantially as described.

2. A cabinet-shave consisting of the stock F, rigid faces B b, separated by slot C, ledge D, and clamp G, pivoted to stock F, and adapted to clamp a cutter, c, against the ledge D, substantially as and for the purpose described.

In testimony whereof I have hereunto set my hand.

JNO. A. KEISER.

Witnesses:

MILTON DASHIELL,

SAML. E. HILLES.