No. 151,682 – Improvement In Planes (Burkner F. Burlington) (1874)

UNITED STATES PATENT OFFICE.

_________________

BURKNER F. BURLINGTON , OF WAKEFIELD, MASSACHUSETTS, ASSIGNOR TO HIMSELF AND JOSEPH CARTWRIGHT, OF SAME PLACE.

IMPROVEMENT IN PLANES.

_________________

Specification forming part of Letters Patent No. 151,682, dated June 9, 1874; application filed January 28, 1874.

_________________

To all whom it may concern:

Be it known that I, BURKNER F. BURLINGTON, of Wakeneld, in the county of Middlesex and State of Massachusetts, have invented certain Improvements in Combination Plane, Square, and Marker, for Clapboarding, &c., of which the following is a specication:

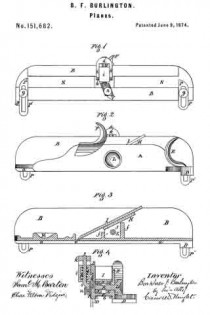

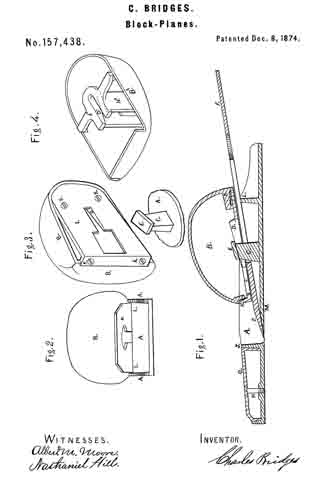

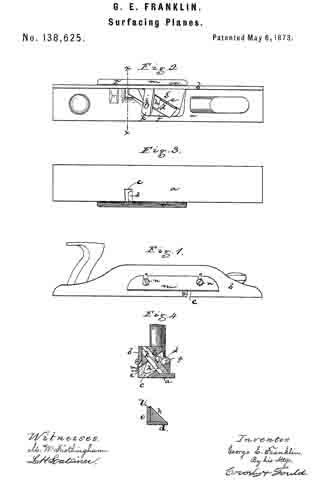

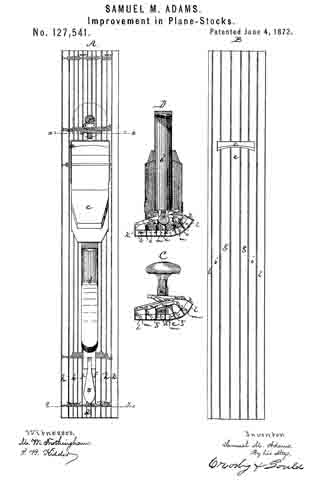

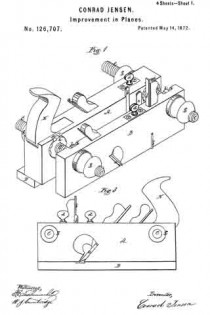

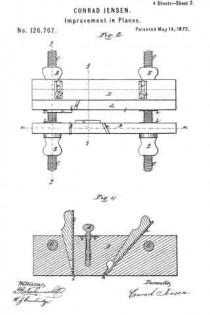

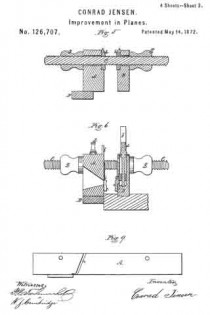

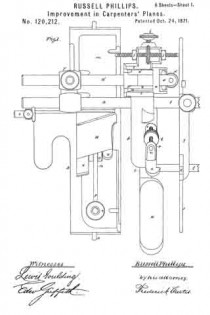

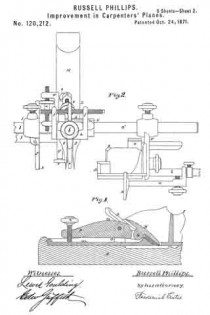

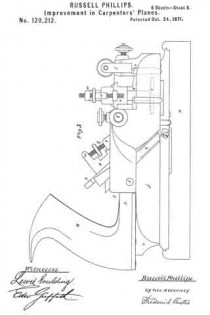

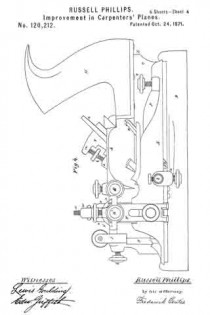

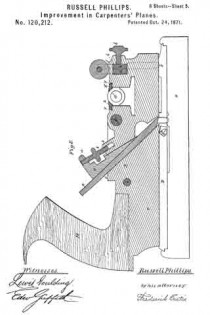

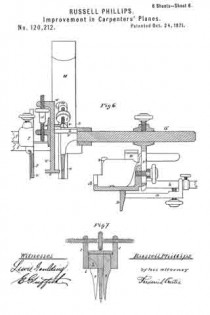

Figures 1 and 2 of the accompanying drawings are side views. Fig 3 is a central vertical longitudinal section; and Fig. 4 is a central transverse vertical section of my improved combination block-plane, square and marker.

The object of the present invention is to provide a compound tool for clapboarding, &c., by the use of which the inconvenience and loss of time heretofore occasioned by the employment of separate tools, is obviated. My invention consists in a simple, economical, and effective compound tool, arranged, as will be hereinafter more fully explained, to be conveniently used as a block-plane for finishing, as well as for clapboarding; as a marker for properly lining the work for cutting; and as a square for squaring the ends of clapboards, finishing, &c. Also, in providing a simple and effective method of holding and allowing the ready adjustment of the plane-iron; in an adjustable traveling marker-head or holder, arranged to hold or release and allow an up-and-down movement of a suitable blade or marker; in forming the bottom of the plane so as to guide it on the work; and in providing the tool with adjustable plates, arranged to admit of its adjustment to the finish at an angle properly to receive the clapboard to be marked for squaring; all of which I will now proceed to describe.

In the drawings, A represents the front side, B the back side, and C the bottom, of a metallic plane. The sides A and B extend below the bottom C, and form flanges or rabbets a a’, between which the work is guided when planed, the groove b, formed between the flanges a a’, being about an inch wide, or of sufficient width to admit seven-eighths finish, or may be of different width, if desired, for other work. The bottom C at the rear extends laterally from the side A in a curved or other desired shape, and is formed at the end with a transverse downward-extending flange or lip, D, that serves as a square with the bottom of the plane, which latter is formed with a transverse mouth, e, beveled at the required angle on its rear edge. The side A is curved downward on the front, and rounded on the bottom at the forward end, or may be otherwise shaped as desired, and is curved downward at the rear end, and formed with a curved or other suitably-shaped thumb-piece, E, and on the top at a proper distance from the thumb-piece E is formed with a curved or other suitably-shaped finger-piece, F. The side A is formed on the inside at or near its center with a lateral projecting plate, G, inclined on the top toward the front, and rabbeted to receive one side of a plate, H, formed on or attached to the under side of a plane-iron, I, the other side of the plate being held by a rabbet formed in an inclined top of a movable plate, J, held between side lugs f f, or otherwise supported, on the interior of the side B. The adjustable plate J is formed with a central transverse screw-aperture that receives one end of a transverse screw, K, whose other end turns in an aperture formed through the inclined plate G and side A, and on the outside is provided with a suitable head, L, concaved on its face to serve as a thumb-rest when the tool is used for planing. By merely turning the screw k, the plate J is adjusted nearer to or farther from the plate G, thus holding or releasing the plate H of the plane-iron I, which is placed upon the top of the plates G and J, so that the plate H is received between the rabbets of the said plates which are inclined at the angle required to bring the bottom of the iron I in the mouth e of the plane. The bottom C is formed on its top near the front with a finger-rest, M, which is ridged up, and depressed in an elliptical form on its upper face. The side B is higher than the side A, and straight on the top, with rounded corners, or may be curved or formed as desired, so as to allow the exterior to be formed with a longitudinal central groove or slot, N, beveled on its edges, or otherwise arranged to receive and admit the longitudinal travel of an adjustable marker-holder or head. Near each end of the side B is formed on the exterior a vertical slot or groove beveled on the edges, or otherwise formed, to receive and allow the up or down adjustment of a slotted plate, P P’, held or released by a screw, g, that engages in the side B, and bears on, so as to hold the plate in the desired position. These plates P P’ are (when it is desired to mark a clapboard the required length) extended so that their ends abut against the finish, the lower plate P’ being extended a distance beyond the upper plate P equal to the difference between the upper and lower widths of the clapboard, thus allowing the tool to be held at the proper angle to receive the clapboard for marking and squaring. Any desired marker may be arranged as preferred to be adjusted and travel on the side B, but in the present example I prefer to use either one of those represented in the drawings. The marker, shown in Figs. 1 and 4 of the drawings. consists of a vertical plate, h, beveled on the top and bottom edge, or otherwise formed, to be held by and travel in the slot or groove N. From about the center of the plate hprojects upward and outward an open box or frame, i, over the open sides of which extend vertical plates, curved or otherwise connected at the top, and forming a movable head, k, to which is attached the top end of a stem, s, that extends vertically through the box i, wherein is a spiral spring, p, surrounding the stem s, for the purpose of restoring the blade of the marker to its original position after its function has been performed. The lower portion of the stem s is curved inwardly and extended laterally, or otherwise shaped, and formed at the back with a flat surface, having a vertical slot or groove beveled or otherwise formed on the edges to receive a pointed or other properly formed blade or marker, r, which is held or adjusted by means of a screw, n, operating through the face of the lower portion of the stem against the blade.

When desired to use the marker represented in Figs. 1 and 4, the head k is pressed down so as to extend the blade r below the bottom of the tool, and the marker is, by means of the plate h traveling in the slot or groove N, carried down so as to draw the blade across the face of the clapboard or finish against which the tool is held, thus marking the work in the desired manner, the blade after performing its function returning, by means of the spring p, to its former position above the bottom of the tool, which is thus left unobstructed by it for further use.

Having thus fully described my improvements, what I claim as my invention, and desire to have secured to me by Letters Patent, is —

1. A block-plane having the plate G, in combination with the transverse screw K, movable plate J, and plane-iron having rib or plate, as described.

2. The plane, substantially as described, having the adjustable plates and traveling marker, adjusting set-screw, and finger-rests, as described.

3. A marker having a vertical plate, h, arranged to travel in the side of a plane and connected or formed with an upward and outward projecting box or frame, i, having a movable head, k, connected with a stem, s, extending vertically through the box, and supplied with a spiral spring, p, the lower portion of said stem projecting inwardly, and formed with a flat rear face, vertically slotted or grooved to receive an adjustable blade, substantially as specified, and for the purpose described.

In testimony whereof I have signed my name to this specification in the presence of two subscribing witnesses.

BURKNER F. BURLINGTON.

Witnesses:

CARROLL D. WRIGHT,

SAML. M. BARTON.