No. 584,002 – Plane-Guide (Erick Lindfors) (1897)

UNITED STATES PATENT OFFICE.

_________________

ERICK LINDFORS, OF MINNEAPOLIS, MINNESOTA.

PLANE-GUIDE.

_________________

SPECIFICATION forming part of Letters Patent No. 584,002, dated June 8, 1897.

Application filed May 7, 1895. Serial No. 548,413. (No model.)

_________________

To all whom it may concern:

Be it known that 1, ERICK LINDFORS, a citizen of the United States, residing in the city of Minneapolis, county of Hennepin and State of Minnesota, have invented a certain new and useful Improvement in Plane-Guides, of which the following is a specification.

My invention relates to means for guiding jointer-planes and in any other kinds of planes, and its object is to provide an adjustably-connected wing or guide whereby the plane may be used for squaring or beveling at different angles the surface operated upon.

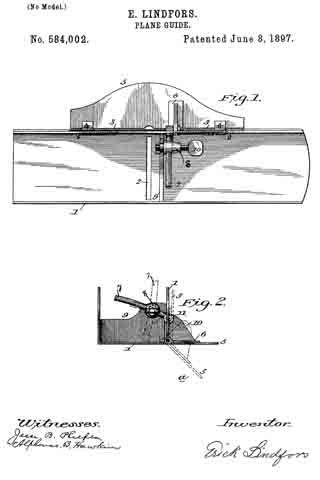

In the accompanying drawings, illustrative of my improvements, there is shown in Figure 1 a plan view of the skeleton of a device embodying my improvements; and in Fig. 2 a transverse section of the same, showing by full and dotted lines different positions of the guiding member relative to the tool while being used for different purposes.

In such drawings a metallic or other suitable frame or stock for carrying a plane-iron is shown by the reference Fig. 1, and the slot in the sole through such iron or bit may be introduced, secured, and adjusted in the ordinary way is shown at 2. The stock shown is a skeleton metal one, but it may be of wood, and a handle (not shown) should of course be provided for operating the tool. These features may be of any usual or suitable construction, for they form no part of the present improvement and are referred to only for the purpose of showing the relationship of the improvement to a form of tool that is well known.

At the side of the tool is suitably hinged, as by means of a wire 3 or pintles, in sockets 4, a wing 5, which serves as the guide in the operation of the tool. This wing has formed on or attached to it an arm 6, on which is formed or to which is attached a suitably-curved extension 7, which may be round or of any suitable shape. These latter members 6 and 7 are arranged to pass through a suitable opening in the side of the stock and the arm 7 to pass through a guiding member 8, supported within the stock by a partition 9 or other suitable support within the body 1, and a set-screw 10 (or other regulating device) is provided for engaging the part 7 to hold it in place in the guide, so as to hold the guide-wing 5 in desired positions of adjustment. As illustrated, the arm 6 and its entension 7 are connected by a pivot 11, and the guide 8 for the part 7 is swiveled in the partition 9. By these means the wing can be turned from an upward to a downward position through an are of about a half-circle, and it may be held in adjustment at any intermediate point by the set-screw 10. The tool may be used in the ordinary way and for the usual purpose of dressing lumber when the wing 5 is in position shown by the full lines in the drawings or is turned upward from such position, and when turned downward, as indicated at a in Fig. 2, it will serve to guide the tool and direct its cutting, so as to form a bevel on the board that is being cut. It will be understood that the wing 5 may be placed either on the upper or side surface of the board to be dressed, depending upon the work desired to be done, so that the blade of the tool as it is advanced will out in a course determined by the angle of inclination of the adjustable member 5, and so by the desired adjustment of this member 5 the tool can be utilized to cut or smooth surfaces within a range of ninety degrees, and by suitable graduations supplied on the arm 7 the degrees of adjustment can be accurately determined and fixed.

Having described my invention, what I claim is —

In a plane, the combination with a stock having a slot in its side and a cavity in its interior, of a guide-wing hinged to the stock adjacent to the slot therein, the curved extension 7 pivotally secured at one of its ends on the guide-wing and entering the slot in the stock, the guide 8 swiveled on the interior of the stock, and having a transverse opening for the reception of the extension 7, and a set-screw to fixedly secure said extension, substantially as described.

ERICK LINDFORS.

Wlitnesses:

ANDREW LIDEN,

J. W. PETERSON.