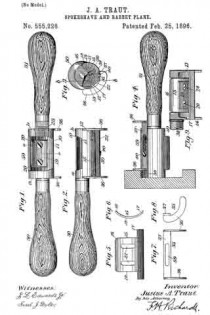

No. 555,228 – Spokeshave And Rabbet-Plane (Justus A. Traut) (1896)

UNITED STATES PATENT OFFICE.

_________________

JUSTUS A. TRAUT, OF NEW BRITAIN, CONNECTICUT.

SPOKESHAVE AND RABBET-PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 555,228, dated February 25, 1896.

Application filed May 31, 1895. Serial No. 551,085. (No model.)

_________________

To all whom it may concern:

Be it known that I, JUSTUS A. TRAUT, a citizen of the United States, residing at New Britain, in the county of Hartford and State of Connecticut, have invented certain new and useful Improvements in Spokeshaves and Rabbet-Planes, of which the following is a specification.

This invention relates to planes, but more particularly to interchangeable spokeshaves and rabbet-planes, and the object of the invention is to provide in one device a tool commonly known as a “spokeshave” adapted to work upon forms of curved or irregular shape, and a plane commonly known as a “rabbet-plane” adapted to shave or plane rabbets in work of irregular or curved shape, and especially for working within a curved rim upon the side of a disk or plate.

A further object of the invention is to provide an improved device in connection with the interchangeable spokeshave and rabbet-plane for regulating or gaging the depth of the cut or shave to be made when the device is used as a rabbet-plane.

A further object of the invention is to also provide an implement or tool, simple and durable in construction, and which will not get out of order in the use thereof, and which is adapted, by means of its particular construction, to work with great accuracy upon many classes of material other than spokes, although the tool is ordinarily termed a “spokeshave.”

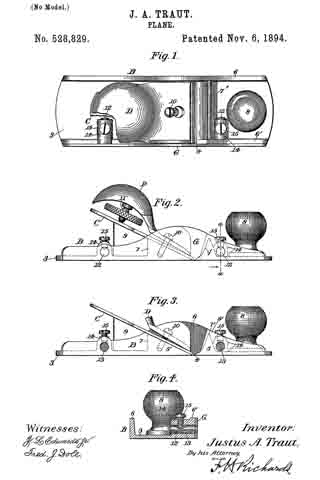

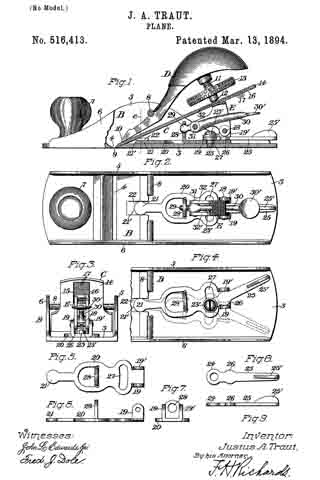

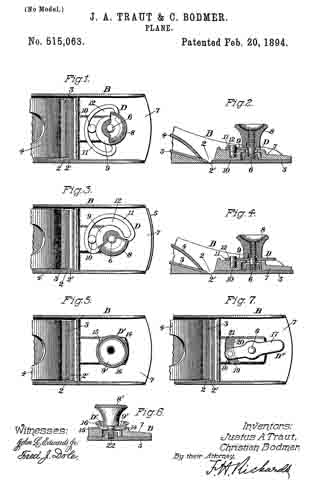

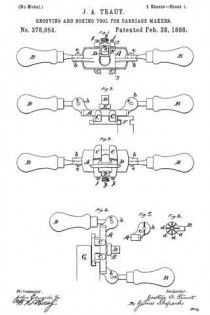

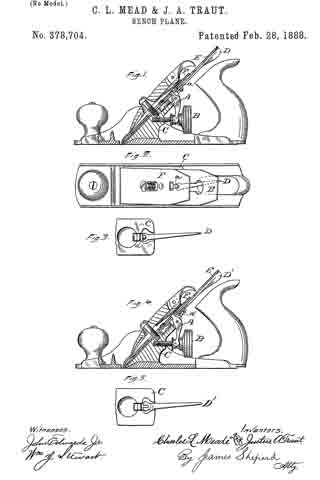

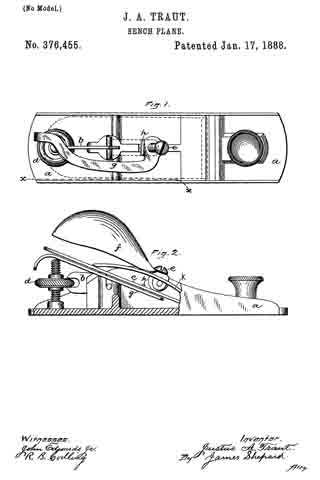

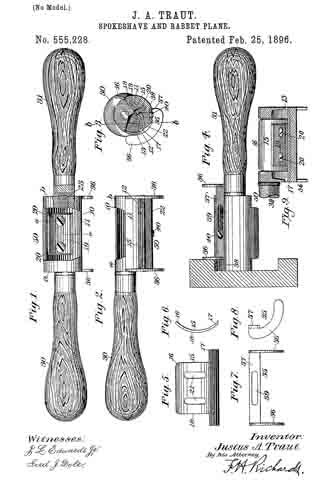

In the accompanying drawings, forming a part of this specification, Figure 1 is a view of the interchangeable tool when used as a spokeshave, showing the open side or chamber of the stock and also showing a part thereof in section. Fig. 2 is a view of the device at right angles to the view shown in Fig. 1 and having one of the handles thereof removed. Fig. 3 is a transverse section of the stock in line a a, Fig. 1, looking toward the left-hand end thereof. Fig. 4 is a view of the interchangeable tool when used as a rabbet-plane and showing it in working position on the rim of a piece of work and also showing the gage in adjusted position to regulate the depth of the shave or cut. Fig. 5 is a detached view of the cutting-knife or bit. Fig. 6 is an end view thereof. Fig, 7 is a view of the gaging device detached from the tool. Fig. 8 is an end view thereof; and Fig. 9 is a partly-sectional view taken in line b b, Fig. 3, for more clearly illustrating the recess 13.

Similar characters of reference indicate corresponding parts in the different figures.

In the preferred form thereof herein shown and described the tool or implement consists of a stock, (designated in a general way by 50,) and is preferably made of metal and of approximately cylindrical shape, whereby it is more especially adapted for work on curved or irregular surfaces.

The stock 50 is cut out or recessed to form a suitable chamber 10 and a concaved seat 11, adapted to contain and support the bit hereinafter described. Extending from end to end of the stock is a suitable slot 12, forming the mouth thereof, and which slot communicates with the interior chambered part of the stock, the lower wall of said slot forming an extension of the concaved seat 11. The interior end walls a and b of the stock are likewise recessed or cut out, as at 13, adjacent to the lower portion of the concaved seat and the mouth of the stock (see Fig. 3) to prevent the clogging of the chips between the knife and the stock.

Seated within the chamber of the stock is a bit (designated generally as 15) of any desired shape and construction suitable for the purpose for which it is to be used, and, as shown in the preferred form thereof, the bit consists of a concave-convex plate, having a shank 16 adapted to fit between the interior end walls a and b of the stock, and a blade 17 projecting beyond the sides of said shank (see Fig. 5) and adapted to work in the slotted ends of the walls and in the mouth of the stock, and extends from end to end or slightly beyond the outer end walls of the stock. (See Fig. 2.)

The convex portion 18 of the shank of the bit is seated in the concaved seat of the chamber, and is adjustably clamped therein by means of a suitable clamping or holding concavo-convex plate 19 and locking devices, preferably binding-screws 20, which project through the elongated slots 21 in the bit and extend into the screw-threaded recesses in the concaved wall of the stock. (See Fig. 1.) By tightening or loosening the binding-screws 20, extending through the elongated slots of the bit, the cutting-edge of the bit can be adjusted in the mouth of the stock to any desired position to adapt it for the work to be done. The outer wall of the approximately cylindrical stock adjacent to the mouth thereof is beveled or flattened to form the sole 22 of the stock.

The stock is provided with suitable handles 30 and 31, removably secured to the stock in any suitable way, and, as shown, the end walls of the stock are provided with suitable screw-threaded apertures into which threaded studs 23, attached to the ends of the handles, are adapted to be screwed, so that when it is desired to use the tool as a rabbet-plane or on work that requires only the use of one of the handles the opposite handle to the one to be used can be quickly and easily removed and the device used either as a spoheshave with one handle or as a rabbet-plane. (See Figs. 2 and 4.)

The particular construction of the stock and the bit, as hereinbefore set forth, in which the ends of the bit project to or slightly beyond the outer end walls of the stock, which end walls form plane bearing-faces, adapts the tool to be used as a rabbet-plane on the removal of one of the handles.

In order to regulate the depth of shave or cut of the bit when the tool is used as a rabbet-plane, a suitable gage or gaging device (designated generally as 35) of a construction adapted for the purpose to which it is to be used is provided and adjustably secured to the stock of the plane.

The gaging device, in the preferred form thereof herein shown, comprises two segmental arms 38, adapted to partially encircle the cylindrical stock and the cutting-edge of the bit, and preferably extends beyond the sole of the stock, (see Fig. 2,) each segmental arm 36, together with suitable means for adjustably securing the same to the stock — such, for instance, substantially as hereinafter set forth-constituting an independent gage for use adjacent to each end of the stock. These segmental arms 36 are preferably integrally united at their inner ends to a sliding bar or member 37, adapted to work in a groove or recess 38 in the outer wall of the cylindrical stock, by means of an elongated slot 39, through which a binding-screw 40 projects into a screw-threaded aperture in the stock. This elongated slot 39 may be of any desired length to permit the gage to be adjusted to any desired position on the stock. For instance, the slot may be extended the entire length of the sliding bar 37, if desired, to permit the tool to shave a recess in a piece of work. of a depth practically the length of the stock.

This improved device for regulating the depth of cut or shave, when the tool is used as a rabbet-plane, not only constitutes a gage but also constitutes a means for protecting the corners of the cutter when the device is used as a spokeshave; but it is obvious that, although the tool is ordinarily designated in the art as a “spokeshave,” the spoke class of work forms but a small percentage of the work upon which the tool may be used. Hence, While the gage acts to regulate the depth of cut, as above stated, when the tool, with one of its handles removed, is used as a rabbet-plane, it is also useful and necessary in connection with the device when used for other purposes than as a rabbet-plane. For instance, if desired to use both handles with the tool, and a groove or recess is to be formed in the straight edge of a board or other material, the gage might be set, as indicated at Fig. 4; or when a certain width of shave is necessary the gage can be adjusted to regulate that width, while at the same time using both handles; or when that portion of the cutter between the ends thereof is used on fine work the gaging device can be adjusted to permit one of its arms to run along the side of the board or other material and thereby act as a guide to prevent the slipping off of the tool.

From the above it will be obvious that the tool can be used as a spokeshave, as a rabbet-plane, or as a tool for many other classes of work, and when the tool is used as an ordinary spokeshave for use on spokes the gage is usually set by means of its elongated slot 39 and binding-screw 40 into the position shown in Fig. 2, and, if desired, both handles attached to the stock. When the tool is to be used for other classes of work, where it is preferably desired to use both handles, the gage is adjusted to the desired position to act as a gage or guide in accordance with the work to be done, whether that portion of the cutter adjacent to one of the outer ends or that portion of the cutter intermediate of its ends is to be used. When, however, the tool is to be used as a rabbet-plane to shave or cut a rabbet of a depth — as, for instance, shown in the work in Fig.4 — one or the other of the handles, 30 or 31, of the tool is removed according to the position of the work to be operated upon, the gage set to the position desired, and the tool is then ready for use.

By having the bit seated in the interior of the stock not only a better appearance is presented but a more rigid and firm seat is formed for the bit, and the same can be more evenly adjusted with relation to the work to be operated upon, while the chamber also forms a means for conducting the chips or shavings of the work that get between the knife edge and the mouth of the stock away from the knife edge and thereby prevents clogging thereof.

Having thus described my invention, I claim —

1. A tool of the class specified, consisting of an appronimately-cylindrical stock, whereby it is adapted to work on curved or irregular surfaces, having its end wall forming a plane bearing-face; a bit joined thereto, and having part of its cutting-blade extending to the plane of such face, whereby it is adapted to cut at the end of said stock.

2. A tool of the class specified, consisting of a chambered stock having its end wall forming a plane bearing-face, and having a mouth; a bit secured in said chamber, and having a part of its cutting-blade extending to the plane of such face, whereby it is adapted to out at the end of said stock.

3. A tool of the class specified, consisting of a chambered, approximately-cylindrical stock having its end walls forming plane bearing-faces, and having a mouth; a bit clamped in the chamber of said stock, and having its cutting-edge adjacent to said month, and having a part of its cutting-blade extending to the planes of such faces, whereby it is adapted to cut at the ends of said stock.

4. ln a tool of the class described, the combination with a chambered, approximately-cylindrical stock, the end walls thereof forming plane bearing-faces, and having a mouth extending from end to end of said stock and substantially adjacent to the plane bearing-faces thereof; of a bit adjustably clamped in the chamber of said stock, and having its cutting-blade of substantially the same length as the mouth of said stock.

5. In a tool of the class described, the combination with a chambered, approximately-cylindrical stock, the end walls thereof forming plane bearing-faces, and having a mouth extending from end to end thereof and substantially adjacent to such plane faces; of a bit adjustably clamped in the chamber of said stock, and having its cutting-blade of substantially the same length as the mouth of said stock; and a gage adjustably secured to said stock.

6. A tool of the class specified, consisting of an approximately-cylindrical stock, whereby it is adapted to work on curved or irregular surfaces, and having its end wall forming a plane bearing-face; a bit joined to the stock, and having a part of its cutting-blade extending to the plane of such face, whereby it is adapted to cut at the end of said stock; and a gage joined to said stock.

7. A tool of the class specified, consisting of a stock having both of its end walls forming plane bearing-faces; a bit joined to the stock, and having a part of its cutting-blade adjacent to each end thereof extending to the planes of such faces, whereby it is adapted to cut at either end of said stock.

8. In a tool of the class specified, the combination of an approximately-cylindrical stock, whereby it is adapted for work on curved or irregular surfaces, the end walls thereof forming plane bearing-faces; a bit adjustably clamped to the stock, and having its cutting-blade extending to the planes of such faces, whereby it is adapted to cut the ends of said stock; and handles removably secured to the ends of said stock, whereby the tool can be used as a spokeshave or as a rabbet-plane.

9. In a tool of the class specified, the combination of an approximately-cylindrical stock, whereby it is adapted for work on curved or irregular surfaces, the end walls of said stock forming plane bearing-faces; a bit adjustably clamped to the stock, and having its cutting-blade extending to the planes of such faces, whereby it is adapted to cut at the ends of said stock; a gage adjustably secured to said stock; and handles removably secured to the ends of said stock, whereby the tool can be used as a spokeshave or as a rabbet-plane.

10. In a tool of the class specified, the combination with a chambered, approximately-cylindrical stock, the end walls of which form plane bearing-faces, and having a mouth extending from end to end thereof; of a bit adjustably clamped in the chamber of said stock, and having its cutting-blade extending substantially adjacent to the planes of such faces;

and removable handles provided with screw-threaded studs adapted to enter screw-threaded apertures in the ends of the stock, whereby the tool can be used as a spokeshave or as a rabbet-plane.

11. In a tool of the class specified, the combination with a chambered, approximately-cylindrical stock, the end walls of which form plane bearing-faces, and having a mouth extending from end to end thereof, and also having a longitudinal recess in its exterior face; of a bit adjustably clamped in the chamber of said stock, and having its blade extending substantially adjacent to the planes of such faces; handles removably secured to the ends of said stock, whereby the tool can be used as a spoke-shave or as a rabbet-plane; and a gage adjustably secured to said stock, and adapted to slide in said longitudinal recess, and regulate the depth of the shave of the tool.

12. In a tool of the class specified, the combination with a chambered, approximately-cylindrical stock, the end walls thereof forming plane bearing-faces, and having a mouth extending from end to end thereof; of a bit adjustably clamped in the chamber of said stock, and having its blade extending substantially adjacent to the planes of such faces; handles removably secured to the ends of said stock, whereby the tool can be used as a spokeshave or as a rabbet-plane; and a gaging device consisting of projecting arms and a sliding bar secured thereto, and adjustably secured to and adapted to slide on said stock to regulate the depth of the shave of the tool.

13. ln a tool of the class specified, the combination with a chambered, approximately-cylindrical stock, the end walls thereof forming plane bearing-faces, and having a mouth extending from end to end thereof; of a bit adjustably clamped in the chamber of the stock, and having its blade extending substantially adjacent to the planes of such faces; handles removably secured to the ends of said stock, whereby the tool can be used as a spoke-shave or as a rabbet-plane; and a gaging device comprising segmental arms, and a sliding bar secured thereto having an elongated slot therein; and means for adjustably securing said gaging device by means of its elongated slot to the stock to permit the same to be adjusted to regulate the depth of the shave of the tool.

14. In a tool of the class specified, the combination with a chambered, approximately-cylindrical stock, the end walls of which form plane bearing-faces, and having a concaved seat therein, and a mouth extending from end to end of said stock, and also having a longitudinal recess on its exterior face; of a concavo-convex bit adapted to be adjustably clamped onto the concaved seat in the chamber of said stock, the blade of said bit extending substantially adjacent to the planes of such faces; handles removably secured to the ends of said stock, whereby the tool can be used as a spokeshave or as a rabbet-plane; a sliding bar adapted to slide in said exterior recess of the stock, and having an elongated slot therein; means for adjustably securing said bar in said recess, and segmental arms secured to said bar, and adapted to partially encircle said cylindrical stock, and adapted to regulate the depth of the shave of the tool.

15. In a tool of the class specified, the combination with a chambered, approximately-cylindrical stock, the end walls thereof forming plane bearing-faces, and having a mouth extending from end to end thereof, of a bit adjustably clamped in the chamber of said stock, and having its blade extending substantially adjacent to the planes of such faces; handles removably secured to the ends of said stock, whereby the tool can be used as a spoke-shave or as a rabbet-plane; and means adjustably secured to said stock for regulating the depth of the shave of the tool.

16. In a tool of the class specified, the combination with a chambered, approximately-cylindrical stock, the end walls of which form plane bearing-faces, and having a mouth extending from end to end thereof, and also having a flattened sole adjacent to said mouth; of a bit adjustably clamped in the chamber of said stock, the shank thereof engaging the interior end walls of the stock, and the blade thereof extending substantially adjacent to the planes of such faces, and handles removably secured to the ends of said stock, whereby the tool can be used as a spokeshave or as a rabbet-plane.

17. In a tool of the class specified, the combination of a stock; the end wall thereof forming a plane bearing-face; a bit joined to the stock, and having a part of its cutting-blade extending to the plane of such face, whereby it is adapted to cut at the end of said stock; a gage secured in position to regulate the depth of the cut of the tool; and a handle removably secured to the end of said stock, whereby the tool can be used as a spokeshave or as a rabbet-plane.

18. In a tool of the class specified, the combination of an approximately-cylindrical stock, whereby it is adapted for work on curved or irregular surfaces, the end walls thereof forming plane bearing-faces; a bit clamped to the stock, and having a part of its cutting-blade extending to the planes of such faces, whereby it is adapted to cut at the ends of said stock; and a gage consisting of a segmental arm having a bar secured thereto having an elongated slot; and means for securing said gage by means of its elongated slot to the stock, whereby it can be adjusted relatively to said stock.

19. In a tool of the class described, the combination with a chambered , approximately-cylindrical stock, the end walls thereof forming plane bearing-faces; and having a concaved seat therein and a mouth extending from end to end of said stock, and substantially adjacent to the plane bearing-faces thereof; of a concave-convex bit adjustably clamped in the chamber of said stock and onto said concaved seat, and having its cutting-blade of substantially the same length as the mouth of said stock ; and a clamping device for adjustably clamping said bit onto the concaved seat of the chamber of the stock.

20. In a tool of the class specified, the combination of a stock, the end wall thereof forming a plane bearing-face; a bit joined to the stock, and having a part of its cutting-blade extending to the plane of such face, whereby it is adapted to cut at the end of such stock; and a handle removably secured to the end of said stock, whereby the tool can be used as a spokeshave or as a rabbet-plane.

JUSTUS A. TRAUT.

Witnesses:

H. S. WALTER,

ROBT. N. PECK.