No. 680,056 – Plane (Edward S. Marks) (1901)

UNITED STATES PATENT OFFICE.

_________________

EDWARD S. MARKS, OF AUBURN, NEW YORK,

ASSIGNOR TO OHIO TOOL COMPANY, OF NEW YORK.

PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 680,056, dated August 6, 1901.

Application filed December 10, 1900. Serial No. 39,447. (No model.)

_________________

To all whom it may concern:

Be it known that I, EDWARD S. MARKS, a citizen of the United States, and a resident of the city of Auburn, in the State of New York, have invented certain new and useful Improvements in Planes, of which the following is a specification.

This invention relates to the devices by which the chisel is adjusted in relation to the plane-stock; and it consists in certain new constructions and arrangements of the parts by which this adjustment is effected.

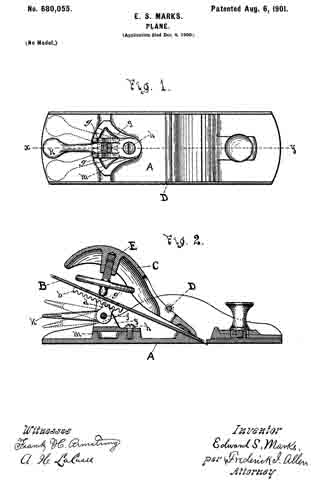

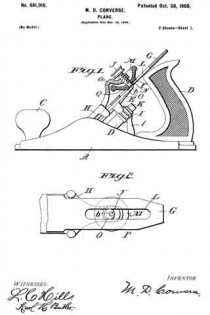

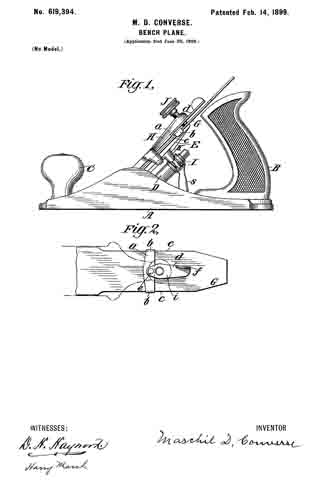

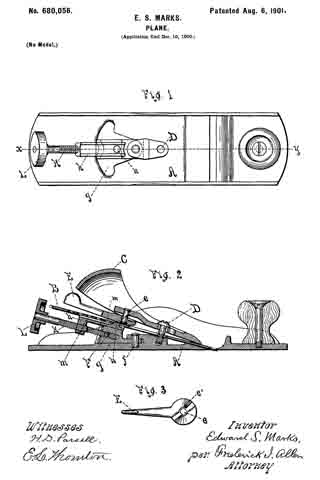

In the drawings, Figure 1 is a plan of a plane-stock provided with my improvements. Fig. 2 is a vertical section upon the line x y of Fig. 1, and Fig. 3 shows the lever separately.

Similar reference-letters indicate like parts in the several views.

In the drawings, A is the plane-stock. B is the chisel, which is secured by means of the cap C, which is held by the screw D and is locked by means of the lever E, pivoted at e and carrying a cam e’.

The foregoing parts are of usual construction.

Upon the plane-stock a carriage F is pivoted at f, which oscillates in the horizontal plane across the bed g. The carriage F is furnished with a slide h, seated thereon, and actuated by a screw K, which extends to the rear of the carriage F and is turned by its head L. A projection n upon the slide h, engages a corresponding depression or aperture m, in the chisel and holds the latter in position.

In operation the lengthwise adjustment of the chisel is performed by rotating the screw K, and by moving the carriage F upon its pivot f crosswise the lateral adjustment of the chisel is effected.

Wliat I claim as new, and desire to secure by Letters Patent, is —

In a plane and in combination; a plane-stock; a chisel mounted therein; means for clamping said chisel in said stock; a carriage pivotally mounted on said plane-stock so as to permit a lateral adjustment of said carriage and the parts supported thereby; a slide mounted on said pivoted carriage, and engaging said chisel ; and means carried by said carriage to adjust said slide and chisel longitudinally.

Signed at Auburn, New York, this 6th day of December, A. D. 1900.

EDWARD S. MARKS.

Witnesses:

H. D. PARSELL,

FREDERICK I. ALLEN.