No. 1,291,856 – Plane (Louis Haneberg) (1919)

UNITED STATES PATENT OFFICE.

_________________

LOUIS HANEBERG, OF BULLRUN, OREGON.

PLANE.

_________________

1,291,856. Specification of Letters Patent. Patented Jan. 21, 1919.

Application filed May 4, 1918. Serial No. 232,617.

_________________

To all whom it may concern:

Be it known that I, LOUIS HANEBERG, a citizen of the United States, residing at Bullrun, in the county of Clackamas and State of Oregon, have invented new and useful Improvements in Planes, of which the following is a specification.

This invention relates to improvements in planes for use by carpenters and other workers in wood and especially with reference to the provision of a tool of this character which may be adjusted or modified in size and thereby adapted for use either as a smoothing plane, a jack-plane or a jointer-plane, as may be desired.

The invention consists in the construction, combination and arrangement of devices hereinafter described and claimed.

In the accompanying drawings:–

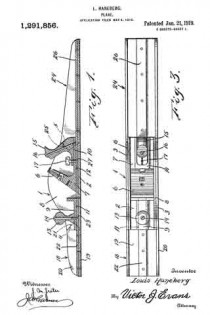

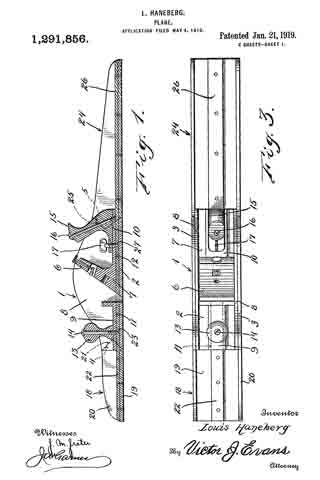

Figure 1 is a vertical longitudinal sectional view of a plane constructed in accordance with my invention, and showing the same arranged for use as a jointer-plane.

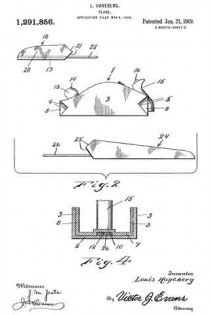

Fig. 2 is an elevation of the same, with the parts disconnected from one another.

Fig. 3 is a plan of the same.

Fig. 4 is a vertical transverse sectional view of the same.

My improved plane comprises a central member or body 1, which is made of iron or steel and comprises a shoe or bottom 2 and side walls or flanges 3. Said walls or flanges are provided in their ends with V-shaped dovetail notches 4, 5 which are reversely arranged as shown, and are respectively at the front and rear ends of the member 1. The frog 6 on which the usual bit is placed is also made of metal and is integral with a plate which bears on the bottom 2 and is formed with side flanges or walls 8 which are secured to the inner sides of the side walls 3 and are co-extensive therewith so that the said flanges or walls 8 form bottoms for the dovetail notches. The central portion of the plate 7 is formed with longitudinally arranged offsets 9, 10 which form slots 11, 12 which extend respectively to the front and rear ends of the member 1. The usual knob 13 is secured on the offset 9 by a screw 14, the lower end of which is conical in form. The usual handle 15 is secured on the oJi`set 10 by a screw 16 and also by a set-screw 17, the lower end of the set-screw being conical.

The body 1 when equipped with a suitable bit forms a smoothing plane.

An extension 18 is provided for the front end of the plane and to form a jack-plane when said extension is attached to the front end of the body 1. The said extension is made of iron or steel and comprises a bottom or shoe 19 and side walls or flanges 20, the rear ends of which are V-shaped as at 21, to form dovetail tongues which are adapted to closely fit in the dovetail notches 4. In the bottom of the extension 18 is a connecting plate 22 which is secured thereto and the rear ortion of which extends rearwardly therefrom and is adapted to enter the slot 11 and is provided with an inverted conical opening 23 for engagement by the lower end of the screw 14 so that the screw serves to firmly draw and clamp the extension 18 against the rear end of the body or member 1 as well as to secure the knob 13 in place.

When the extension 18 is thus secured to the rear end of the member 1 the plane is arranged for use as a jack-plane, as will be understood.

I also provide a rear extension 24 which is similar in construction to the construction 18 and the side walls of which are provided at their front ends with V-shaped tongues 25 to enter the notches 5. The connecting plate 26 of the extension 24 projects at its front portion from the front end of said extension and is adapted to enter the slot 12 and has a conical opening 27 with which the conical lower end of the set-screw 17 engages so that said set-screw serves to closely draw and clamp said extension 24 to the rear end of the member 1.

When the extension 24 is thus secured the plane forms a jointer-plane.

Owing to the provision of the side walls 8 of the frog member 6 and which cover the inner sides of the dovetail notches the dove-tail projections or tongues of the front and rear extensions bear directly against said walls or flanges 8 and lateral displacement of the extensions 18 and 24 is absolutely prevented so that the side walls of the main member 1 and the extensions 18 and 24 all lie in exactly the same planes and present unobstructed smooth outer surfaces, adapting the plane for use on fine work.

While I have herein shown and described a preferred form of my invention, I would have it understood that changes may be made in the form, proportion and construction of the several parts, without departing from the spirit of my invention and within the scope of the appended claims.

Having thus described my invention, I claim :–

1. In a plane, a main member having a longitudinally arranged slot, an extension member having a connecting plate projecting therefrom and arranged to enter the slot, a handle on the main member and a screw securing the handle to the main member and also securing the plate in the slot.

2. In a plane, a main member having a longitudinally arranged slot, an extension member having a connecting plate projecting therefrom and arranged to enter the slot, a handle on the main member and a screw securing the handle to the main member and also securing the plate in the slot, said plate having a conical opening and the screw having a conical point to engage in said opening.

3. In a plane, a main member having side walls provided with notches at the ends, said main member being also provided with a frog member having side walls which form the inner sides or bottoms of said notches, extension members for the plane having side walls provided with projections to enter said notches and means to detachably secure said extension members.

4. In a plane, a main member, a frog member in the main member and provided with a bottom portion having an offset forming a longitudinal slot, and an extension member having a plate projecting therefrom and arranged to engage in said slot.

In testimony whereof I affix my signature.

LOUIS HANEBERG.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________