No. 548,582 – Shavings-Guide For Carpenters’ Planes (Lewis B. McDonald) (1895)

UNITED STATES PATENT OFFICE.

_________________

LEWIS B. McDONALD, OF LITTLE ROCK, ARKANSAS.

SHAVINGS-GUIDE FOR CARPENTERS’ PLANES.

_________________

SPECIFICATION forming part of Letters Patent No. 548,582, dated October 22, 1895.

Application filed March 31, 1894. Renewed March 28, 1895. Serial No. 543,596. (No model.)

_________________

To all whom it may concern:

Be it known that I, LEWIS B. McDONALD, a citizen of the United States, and a resident of Little Rock, in the county of Pulaski and State of Arkansas, have invented certain new and useful Improvements in Shavings-Guides for Carpenters’ Planes; and I do declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it appertains to make and use the same, reference being had to the accompanying drawings, and to the letters of reference marked thereon, which forin a part of this specification.

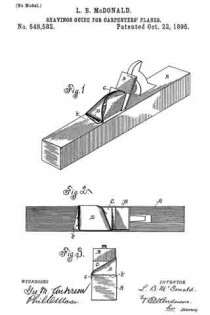

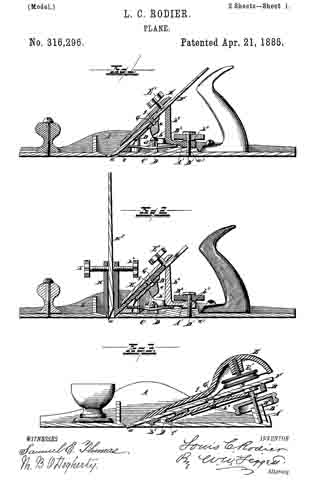

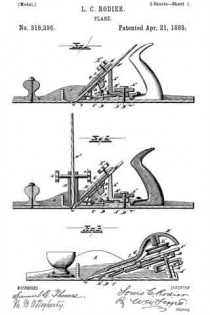

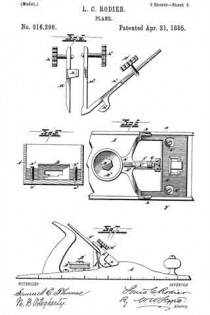

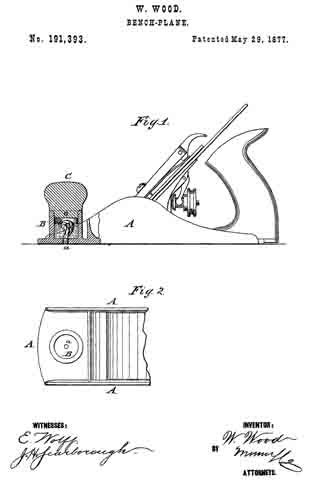

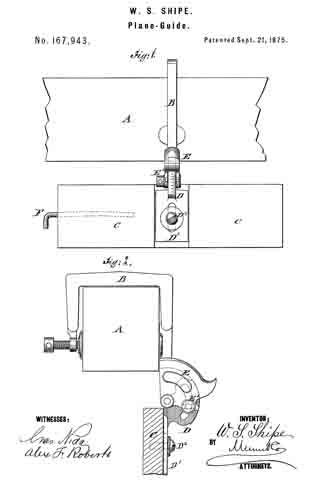

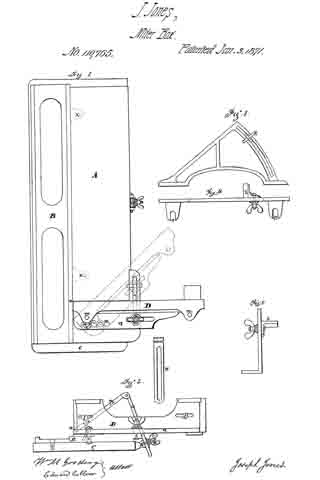

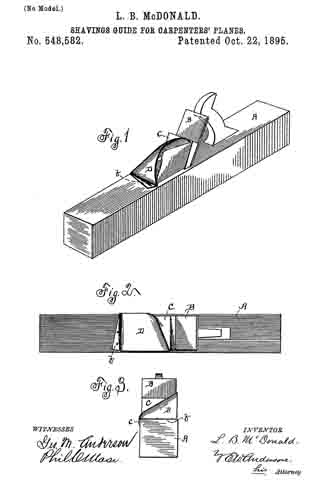

Figure 1 of the drawings is a representation of a perspective view of the guide applied. Fig. 2 is a plan view of same, and Fig. 3 is a front end view of same.

This invention has relation to certain new and useful improvements in shavings-guides for carpenters’ planes; and it consists in the novel construction and combination of parts, all as hereinafter described, and pointed out in the appended claims.

The object of the invention is to provide a carpenter’s plane with a simple and effective device of improved character for throwing the shavings from the plane off the bench.

Referring to the accompanying drawings, the letter A designates the stock, B the bit or iron, and C the wedge.

D is the guide, which constitutes the present invention in its combination with the stock in the manner presently described.

This guide consists of a piece of metal bent or arched upwardly over the opening D’ in the stock forward of the wedge, the transverse rear edge a of the metal resting against or in close proximity to the wedge and inclosing with the wedge said opening on three sides. The open side is at the longitudinal front face of the plane, and the guide is inclined downwardly from this side to the opposite side, which causes the chamber formed thereby to gradually increase in height from the back to the front longitudinal edge of the plane. By this arrangement the shavings forced up through the stock into this chamber readily clear themselves and are forced out of the open side of the guide and off the bench.

In some cases, in planes with metal stocks, I may prefer to cast the guide integral with the stock, or it may be a separate piece and be secured thereto by screws or othersuitable means. In the latter case a flange b is formed at the forward edge of the guide to receive the securing-screws, the rear longitudinal edge having, also, a flange c, which is secured to the rear longitudinal face of the stock.

When made separate, the guides will be in different sizes and may be readily applied to any of the ordinary styles of planes having either wooden or metal stocks.

Having thus described my invention, what I claim as new, and desire to secure by Letters Patent, is —

1. The combination with a plane stock and the wedge, of a shavings guide therefor, said guide comprising a plate portion attached to the stock and arched or bent over the opening therethrough and inclosing said opening, with the aid of the wedge, upon three sides, substantially as specified.

2. As a new article of manufacture, a shavings guide for carpenters’ planes, said guide comprising a plate portion arched or bent to adapt it to fit over and around the opening in a plane, and against the wedge thereof, and with said wedge inclose it upon three sides, and having danges for its attachment to a plane stock, substantially as specified.

In testimony whereof I anis my signature in presence of two witnesses.

LEWIS B. MCDONALD.

Witnesses:

JULIUS BRUNDT,

HENRY GRAMLING.