No. 160,132 – Improvement In Planes (George L. Weaver) (1875)

UNITED STATES PATENT OFFICE.

_________________

GEORGE L. WEAVER, OF HARTFORD, CONNECTICUT.

IMPROVEMENT IN PLANES.

_________________

Specification forming part of Letters Patent No. 160,132, dated February 23, 1875; application filed May 23, 1874.

_________________

To all whom it may concern:

Be it known that I, GEORGE L. WEAVER, of Hartford, in the county of Hartford and State of Connecticut, have invented a new and valuable Improvement in Planes; and I do hereby declare that the following is a full, clear, and exact description of the construction and operation of the same, reference being had to the annexed drawings making a part of this specification, and to the letters and figures of reference marked thereon.

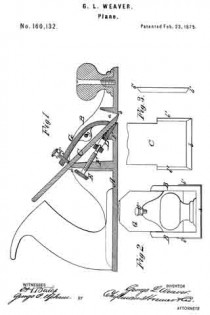

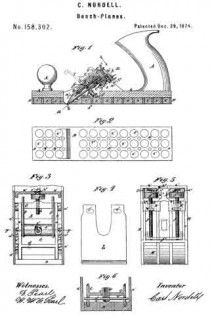

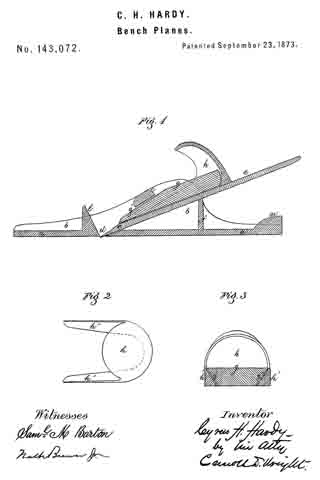

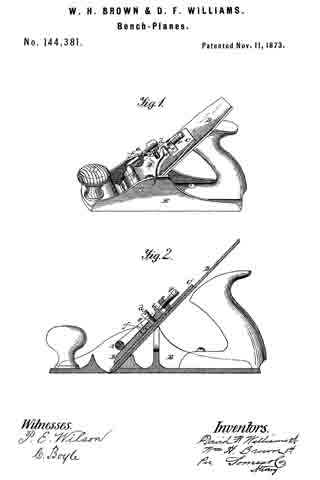

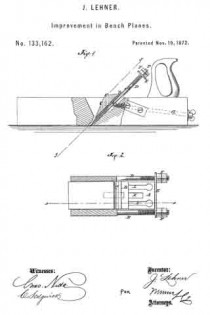

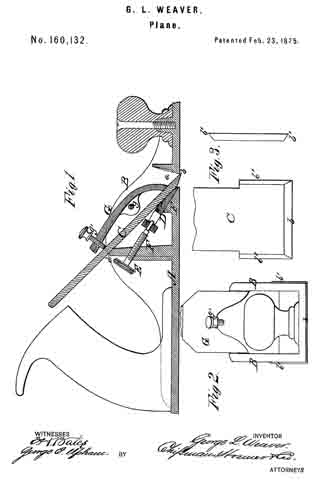

Figure 1 of the drawing is a representation of a sectional view of plane, and Fig. 2 is an end view of the same. Figs. 3 are detail views.

This invention has relation to hand-planes; and it consists in a novel construction of the stock-frame, having stationary inclined beds, and the adjustable wedge having its upper beveled surface parallel with the cutting-iron, as hereinafter more fully described and claimed.

In the annexed drawings, A designates a metal plane-stock, which is constructed with two sides or cheeks, B B, the outer faces of which are perpendicular to the sole of the plane, as shown in Fig. 2. C designates the plane iron or bit, which is supported upon an adjustable bed, D, and a stationary bed, F, and which is rigidly secured thereupon by means of a clamp, G, which is pivoted to cheeks B, at g, and provided with a set-screw, g’. The bed D is wedge-shaped, with an angle coincident to that of the stationary bed F, and parallel with the plane or cutting iron, and is adjustable by means of a screw, E, which adjustment will allow the throat or mouth a to be enlarged or diminished as circumstances require. At the same time the wedge D aftbrds a rigid support for the plane-iron near its lower cutting-edge b. F’ represents a standard, extending upward from the stock, and having its upper end beveled at d, directly opposite the set-screw g’ ofthe clamp, to aftord a bearing-surface for the upper portion of the cutting-iron C. By this construction the cutting-iron C is firmly secured at its lower and upper edges to the inclined beds F d by means of the clamp G and set-screw g’, as shown in Fig. 1.

I am aware that a wedge arranged between the cutting-iron and the bed of the stock, operated by a screw to adjust the cutting-iron, is not new, and therefore I do not claim such invention, broadly; but

What I claim as new is —

The hand-plane herein described, having the stationary inclined beds F d, the adjustable wedge-shaped bed D, having an angle coincident with that of the bed F, and a beveled surface parallel with the cutting-iron C, and affording, with the bed d, a rigid support for the same, and the clamp G, with its set-screw g’, all combined for the purpose set forth.

In testimony that I claim the above I have hereunto subscribed my name in the presence of two witnesses.

GEORGE L. WEAVER.

Witnesses:

FREDERICK EBERLE,

EUGENE D. FISK.