No. 1,092,326 – Fastening For Plane-Bits (John Bahmiller) (1914)

UNITED STATES PATENT OFFICE.

_________________

JOHN BAHMILLER, OF SALEM, OHIO.

FASTENING FOR PLANE-BITS.

_________________

1,092,326. Specification of Letters Patent. Patented Apr. 7, 1914.

Application filed November 25, 1912. Serial No. 733,449.

_________________

To all whom it may concern:

Be it known that I, JOHN BAHMILLER, a citizen of the United States, residing at Salem, in the county of Columbiana and State of Ohio, have invented certain new and useful Improvements in Fastenings for Plane-Bits, of which the following is a specification, reference being had to the accompanying drawings.

This invention relates to new and useful improvements in fastenings for plane-bits and has for its object to provide a fastening which will admit of the bit being readily adjusted to the various positions desired.

A further object of the invention resides in providing a bit having a central longitudinal slot, the one wall of which is provided with rack teeth and a still further object resides in providing means on the securing member between the bit and cap-iron adapted for cooperation with said rack teeth to adjust said bit to its various positions.

A further object of the invention resides in providing a device which is extremely simple and durable in construction, inexpensive to manufacture and one which will be very eflicient and useful in operation.

With these and other objects in view, the invention consists in the novel features of construction, combination and arrangement of parts as will be hereinafter referred to and more particularly pointed out in the specification and claim.

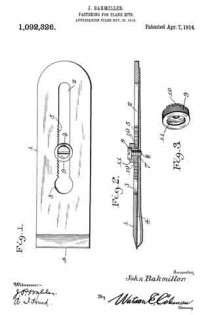

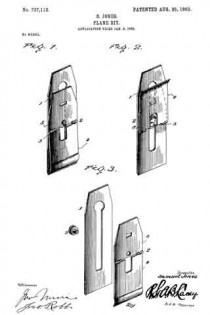

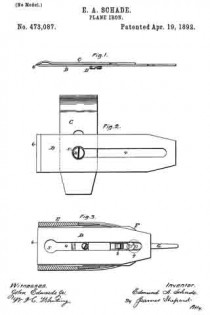

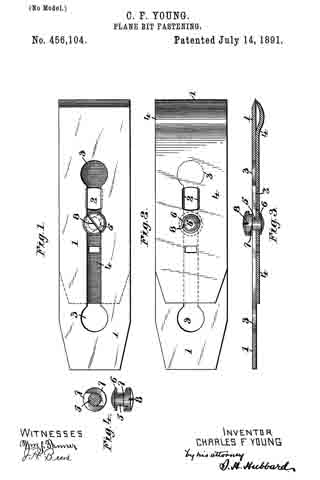

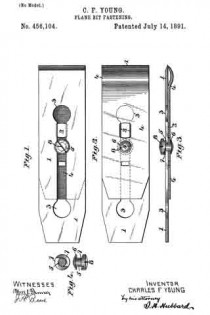

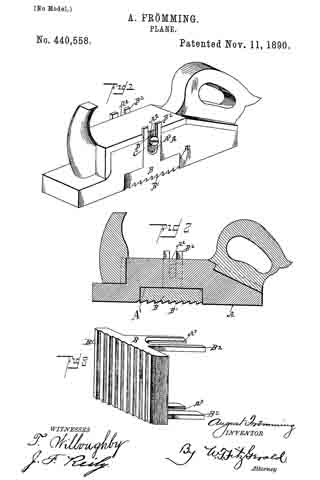

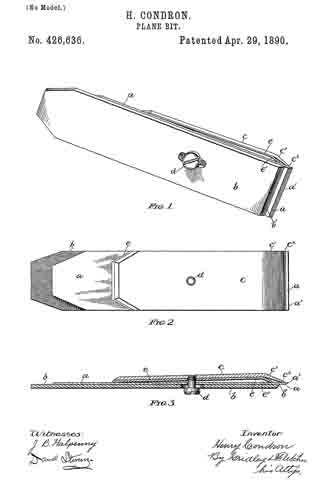

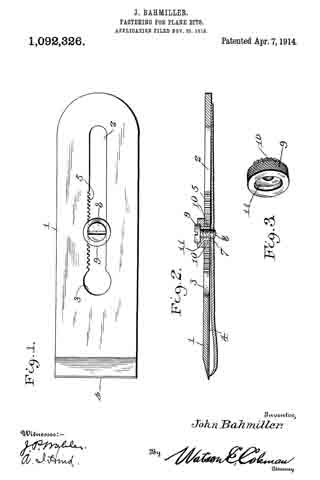

In the accompanying drawing forming a part of this application, Figure 1 is a plan view of a bit showing my improvements applied to use thereon. Fig. 2 is a vertical longitudinal section therethrough; and Fig. 3 is a perspective view of the sleeve member adapted to cooperate with the rack teeth on the bit.

In describing my invention, I shall refer to the drawing in which similar reference characters designate corresponding parts throughout the several views and in which —

1 indicates a bit such as is used in the usual bench plane or the like, the same being provided with a central longitudinal slot 2, the forward end of which is enlarged as shown at 3. The under face of the bit 1, at the outer end thereof, has counter-sunk therein and welded or otherwise similarly secured thereto, the hard metal surface 4, which extends to the cutting edge thereof and one wall of the slot 2 is provided with rack teeth for the greater portion of its length, as shown at 5. A cap-iron 6 of the usual construction, is also provided, the same having an opening 7 therein, and any other such openings as are demanded by the construction of the plane to which the same is to he applied. This opening 7 is threaded and adapted to receive in engagement therewith, the threaded end of a screw 8 which is extended through the slot 2 of the bit 1. In order to adjustably secure the bit and cap-iron together, however, and properly support the screw 8, I provide a substantial sleeve member 9, which is greater in diameter than the width of the slot 2 and is externally reduced at one end thereof to permit a portion thereof to extend through said slot. This reduced portion is of substantially the same diameter as the width of said slot and is provided with rack teeth, as shown at 10, to engage the teeth 5 in the one wall of said slot. This reduced portion with its rack teeth 10 thereon forms a substantial gear and the outer periphery of the enlarged upper portion of said member 9 is knurled to be readily grasped by the operator and turned. The inner periphery of this sleeve member from the enlarged end thereof, is increased in width as shown at 11 to provide an annular shoulder and as the screw 8 is adapted to extend through this sleeve member, the head of said screw may be readily seated on this annular shoulder.

In setting up the device, the sleeve member 9, with the screw 8 extended therethrough, is first disposed in the enlarged portion 3 of the slot 2 and the cap-iron 6 brought into position to be engaged with the threaded end of said screw. The sleeve is then moved into the slot 2 until the teeth 10 are engaged with the teeth 5 of said slot, whereupon said member 9 is rotated until the bit is properly adjusted with respect to the cap-iron. When the proper adjustment has been made, the screw 8 is then turned until the same securely clamps said member 9 in its adjusted position and the bit is then ready for use. Should, during the operation of the plane, it be desired to adjust said bit, it is only necessary to turn the screw 8 in the opposite direction to loosen the same, whereupon the member 9 may be rotated, which operation will adjust said bit on the cap-iron. The screw is then tightened to securely retain the bit in the desired position.

From the foregoing it will be seen that I have provided a simple, inexpensive and efficient means for carrying out the objects of the invention, and while I have particularly described the elements best adapted to perform the functions set forth, it is obvious that various changes in form, proportion and in the minor details of construction may be resorted to without departing from the spirit or sacrificing any of the principles of the invention.

The hard metal surface 4 which is counter-sunk in the under face of the bit 1, and extends to the cutting edge thereof, is a plate which will prevent the cutting edge from being unnecessarily nicked during the use of the device and thereby obviate the necessity of constantly sharpening the same, The provision of such a plate on the bit will not materially add to the cost thereof and in the end will save considerable time and expense.

Having thus described this invention, what I claim is:–

In a plane, the combination with a cap iron having a threaded opening arranged about centrally therein; of a bit provided with a longitudinal slot terminating in an enlargement at one end thereof, one wall of said slot being provided with teeth extending for the greater portion of its length, a sleeve disposed in the slot of said bit having teeth formed on the outer periphery thereof, in engagement with the teeth of the one vvall of said slot, the teeth on said sleeve also contacting lightly with the opposite wall of said slot to prevent a loose movement of the sleeve therein, a disk-like head member formed on the upper end of said sleeve to project on opposite sides of the slot in said bit and rest on the top face of the latter, said head member being of less diameter than the diameter of the enlargement of said slot and provided with a socket in the top face thereof, means provided on the outer peripheral edge of the head member, whereby to readily grasp the same, and a headed screw disposed through said sleeve and engaged at its lower end with the threaded opening of said cap iron, the head of said screw being received snugly in the socket of the head of said sleeve to bind tightly therein and retain the bit in any adjusted position with respect to the cap iron.

In testimony whereof I hereunto affix my signature in the presence of two witnesses.

JOHN BAHMILLER.

Witnesses:

K. L. COBOURN,

MYRTA L. COBOURN.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________