No. 679,702 – Spokeshave (Walter D. Murray) (1901)

UNITED STATES PATENT OFFICE.

_________________

WALTER D. MURRAY, OF PORTLAND, MAINE, ASSIGNOR,

OF ONE-HALF TO WALTER ACKROYD, OF SAME PLACE.

SPOKESHAVE.

_________________

SPECIFICATION forming part of Letters Patent No. 679,702, dated July 30, 1901.

Application filed May 31, 1900. Serial No. 18,627. (No model.)

_________________

To all whom it may concern:

Be it known that l, WALTER D. MURRAY, a citizen of the United States, residing at Portland, in the county of Cumberland, in the State of Maine, have invented certain new and useful lmprovements in Spokeshaves, of which the following is a specification.

This invention relates to that class of wood-working planes known as spokeshaves.

One object of the invention is to provide a spokeshave with a detachable reversible sole-piece, either edge of which may be used to vary the form of the spokeshave to adapt it for either concave or straight work.

Another object of the invention is to provide simple and effective means for raising and lowering the blade, whereby either end thereof may be moved as desired independently of the other to seen re accuracy of adjustment.

Another object is to provide improved handles for the spokeshave for insuring a better grip and a steadier working tool.

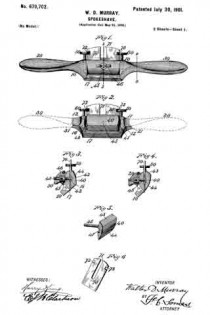

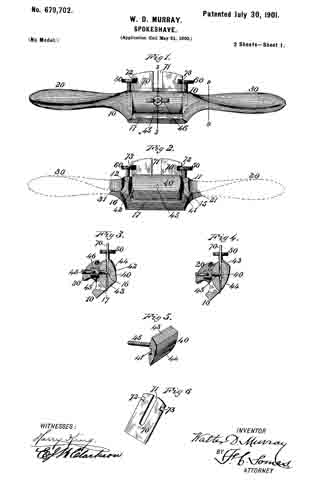

Figure 1 of the accompanying drawings represents a front elevation of this spokeshave. Fig. 2 represents a rear elevation thereof. Fig. 3 represents a central transverse section on line 3 3 of Fig. 1. Fig. 4 represents a similar section with the sole-piece reversed. Fig. 5 represents a perspective view of the detachable sole-piece. Fig. 6 represents a perspective view of the blade or cutter. Fig. 7 represents a rear elevation of the stock, the detachable sole-piece being removed. Fig. 8 represents another form of connection between the blade and the adjusting-screws therefor. Fig. 9 represents an end view of the stock, one of the handles being shown in section on line 9 9 of Fig. 1.

The same reference numbers indicate corresponding parts in all the figures.

In the form of spokeshave illustrated in the accompanying drawings a body or stock 10, having handles 20 and 30 at its opposite ends, is recessed at its back to receive a detachable sole-piece 40. The recessing of the stock forms a rear bed for the blade and shoulders 11 and 12, against which the ends of the sole-piece 40 abut. These shoulders 11 and 12 are provided with screw-threaded sockets 13 and 14, adapted to receive headed screws 50 and 60, respectively, the object of which will be hereinafter described. This stock is provided with a slot 17, through which the shavings pass. Means are provided on the stock and sole-piece for adjusting the latter incorrect position, and these means may consist of lags on one part and notches in the other. When constructed as here shown, the stock 10 is provided at the opposite ends of its recessed bed with lugs 15 and 16, adapted to engage notches 41 and 42, formed in the opposite ends of the sole-piece 40, whereby the proper adjustment of the sole-piece is accomplished.

The detachable sole-piece 40 is preferably constructed with its opposite edges in different forms, being shown as provided with a flat edge 43 and with a rounded edge 44,and either edge may be used to vary the shape of the spokeshave, as desired, by reversing the sole-piece.

Suitable means are provided for fastening the detachable sole-piece to the stock. In the form shown this sole-piece 40 has a screw-threaded shank 45 extending at right angles from the center of its inner face. This shank 45 may consist of a screw passed through the sole-piece or it may form a part of a bolt, the sole-piece 40 constituting the head thereof. This shank or bolt 45 extends through a perforation 18 in the stock 10, and the outer end thereof is engaged by a thumb-nut 46, which firmly clamps the sole-piece to the stock.

A blade 70, having a longitudinal slot 71 therein, is disposed in the recessed portion of the stock; 10, between it and the sole-piece 40. The bolt 43 of the sole-piece passes through the slot 71 before entering the perforation 18 of the stock, and the screwing down of the thumb-nut 46 thereon clamps the knife 70 firmly in position between the stock and the sole-piece. This blade 70 is provided at its opposite ends, near its top, with means for engaging the adjusting-screws 50 and 60, respectively. In the form shown in Figs. 1 and 2 these means consist of notches 72 and 73. In the form shown in Fig. 8 they consist of lateral lugs 74, which engage grooved or double heads 51 and 61 on the adjusting-screws. This blade may be adjusted at any desired height by simply turning the screws in the direction desired, and either end thereof may be independently raised or lowered to secure accuracy of adjustment by raising or lowering the screw connected therewith. Concave recesses 21 and 31, disposed substantially in a vertical plane and at right angles to the sole of the shave, are formed at the ends of the stock and extend through the adjacent portions of the handles 20 and 30, on the rear side of the latter. These recesses serve as finger-rests for the index-fingers when the shave is grasped in the hands and afford a better grip for the operator and a steadier working tool.

Either the means for adjusting the blade, the peculiar form of handles, or the detachable sole-piece may be applied to any adaptable form of spokeshave.

I claim as my invention —

1. A spokeshave having a detachable rear sole-piece serving as a clamp for the blade.

2. A spokeshave having a detachable reversible rear sole-piece.

3. A spokeshave having a reversible rear sole-piece provided with edges of different forms.

4. A spokeshave provided with a reversible rear sole-piece having edges of different forms, one of said edges being flat and the other rounded.

5. A spokeshave comprising a recessed stock, a blade adapted to fit in said recess, a reversible sole-piece also adapted to fit in said recess behind said blade, said stock being provided with means for engaging said sole-piece, and means for securing the blade and sole-piece to the stock.

6. A spokeshave comprising a stock provided with a recess at its back, a reversible sole-piece, adapted to fit in said recess, interlocking means on said stock and sole-piece, a blade disposed between said stock and sole-piece, and means for securing said sole-piece and blade to said stock.

7. A spokeshave comprising a stock provided vvith a recess at its back and lugs at opposite ends of said recess, a reversible sole-piece adapted to fit in said recess and provided with notches adapted to engage said lugs, a blade disposed between said sole-piece and stock, and means for securing said blade and sole-piece to said stock.

8. A spokeshave comprising a recessed stock having a perforation therein, a detachable rear sole-piece having a bolt attached thereto and adapted to extend through said perforation, a thumb-nut adapted to screw on said bolt and fasten the sole-piece in position, and a blade clamped between said sole-piece and stock.

9. In a spokeshave the combination of a stock provided with a blade-bed and with screvv-sockets adjacent to opposite ends of said bed, a blade provided with notches at its opposite ends, means for clamping said blade to said bed, and adjusting-screws disposed in said sockets and provided with heads engaging said lateral notches.

10. A spokeshave comprising, a stock and handles extending from opposite ends thereof, vertical concave recesses being formed at the ends of the stock and adjacent portions of the handles on the rear side of the latter, which recesses serve as rests for the index-fingers when the shave is grasped by the hands.

WALTER D. MURRAY.

Witnesses:

ALICE H. SULIVAN,

JOSEPH E. DANAHER.