No. 355,031 – Bench-Plane (Samuel D. Sargent) (1886)

UNITED STATES PATENT OFFICE.

_________________

SAMUEL D. SARGENT, OF NEW BRITAIN, CONNECTICUT, ASSIGNOR TO

THE STANLEY RULE AND LEVEL COMPANY, OF SAME PLACE.

BENCH-PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 355,031, dated December 28, 1886.

Application filed September 6, 1886. Serial No. 212,803. (No model.)

_________________

To all whom it may concern:

Be it known that I, SAMUEL D. SARGENT, a citizen oi the United States, residing at New Britain, in the county of Hartford and State of Connecticut, have invented certain new and useful Improvements in Bench-Planes, of which the following is a specification.

My invention relates to improvements in bench-planes, and has particular relation to the manner of holding the cutting-bit within the stock.

One object of my improvement is to produce a plane in which the bit can be clamped by fewer and more direct motions, and therefore more conveniently, than heretofore.

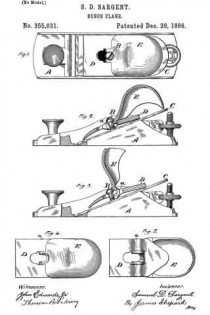

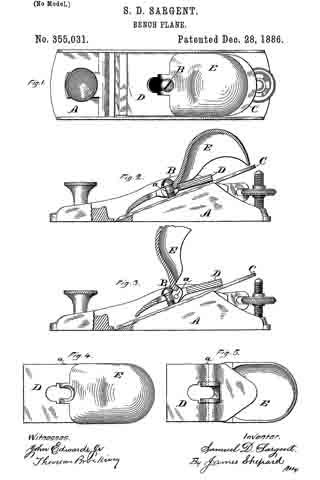

In the accompanying drawings, Figure 1 is a plan view of my plane. Fig. 2 is a side view of the same, partly in section and partly in elevation. Fig. 3 is a like view with the holding-cap placed in position with its lever raised ready for clamping the bit. Fig. 4. is a plan view of my holding-cap and its lever detached from the plane, and Fig. 5 is a like view of the reverse side of the same.

The stock A and the means for adjusting the cutting-bit after it is clamped within said stock may be of any ordinary construction.

B designates a headed screw set in a threaded hole in the frog or stock in the ordinary manner of this class of planes, so that by screwing it in or out the distance between the under side of the screw-head and the upper side of the cutting-bit C may be adjusted. A fixed stud with an adjustable head or a headed bolt adjusted by a nut would be the equivalent of this screw.

D is the holding cap or wedge, having a hole near its center, as viewed in plan view, which hole is large enough to let the head of the screw B pass through it. Pivoted to this cap by means of the pintle a is the clamping-lever E, the upper end of which is preferably of a form which will serve as a handle for the plane, while its lower and short end is slotted to take under the head of the screw upon two sides. The slot in this lever opens into the central hole in the cap. Said slot also extends both forward and backward of the pintle a, and hence said pintle is in two parts — one on each side of said slot — as indicated by the broken lines in Fig. 5.

The holding-cap is so formed on its under side as to bear upon the cutter only at the ends of said cap. After setting the bit in place the holding-cap and attached lever are placed on the bit (or on the cap-iron in case of a double plane-iron) by letting the central hole pass over the screw-head, then slipping the holding-cap downward to let the slotted end of the lever under the head of the screw, as shown in Fig. 3. The long end of the lever E is then depressed, when said lever fulcrums on the under side of the screw-head and carries the holding-cap downward into the position shown in Fig. 2, in which the pintle a (indicated by the broken circle) is slightly in advance of the lever on the screw-head, and consequently the pressure on the screw will hold the lever in its clamping position. If the adjusting-screw is properly set, the bit will be then firmly clamped. In putting in the clamping device the operator takes hold of the handle only and sets the holding-cap in place, then merely presses the outer end of the handle obliquely downward with only one motion. It will thus be seen that in clamping the bit the movement of the cap and lever-handle is practically in the same direction — forward and downward — and therefore these parts are more conveniently handled than parts which require to be moved in reverse directions — as, for instance, when the lever requires to be first moved backward and upward, as is the case in several prior planes. The clamping mechanism is also believed to be very efficient.

I claim as my invention —

In a plane, the combination of the holding-screw B, the holding-cap D, adapted to bear at each end upon the bit, and the clamping-lever pivoted or hinged to said cap between the bearing ends and having its upper face adapted to engage and fulcrum upon the under side of the screw-head, substantially as described, and for the purpose specified.

SAMUEL D. SARGENT.

Witnesses:

F. N. STANLEY,

W. J. WORAM.