No. 1,104,454 – Plane (William E. Sparks) (1914)

UNITED STATES PATENT OFFICE.

_________________

WILLIAM E. SPARKS, OF NEW HAVEN, CONNECTICUT, ASSIGNOR TO SARGENT &

COMPANY, OF NEW HAVEN, CONNECTICUT, A CORPORATION OF CONNECTICUT.

PLANE.

_________________

1,104,454. Specification of Letters Patent. Patented Jul. 21, 1914.

Application filed July 11, 1913. Serial No. 778,591.

_________________

To all whom it may concern:

Be it known that I, WILLIAM E. SPARKS, a citizen of the United States, residing in the city and county of New Haven and State of Connecticut, have invented certain new and useful Improvements in Planes, of which the following is a full, clear, and enact description.

This invention relates to planes, and more particularly to reversible rabbet planes.

The plane selected for illustration is of the type known as a show-case plane, it being adapted to cut the rabbets of showcases by movement in either direction.

The primary object of the invention is to provide a simple, efficient form of reversible rabbet plane in which reversal may be effected without adjustment of the cutting mechanism. To this end, the plane is provided with two cutters having a novel relation to each other and to the body or stock and clamped on the stock in a novel manner.

The invention also aims to improve certain general and detail features of construction in planes of the class to which my invention relates.

To these and other ends, the invention consists in the novel features and combinations of parts to be hereinafter described and claimed.

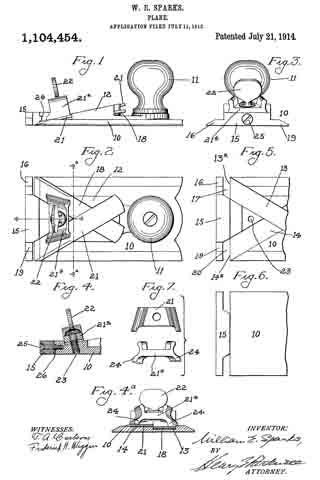

In the accompanying drawing, Figure 1 is a side elevation of a plane embodying my improvements, Fig. 2 is a top plan view of the same, Fig. 3 is a front end view, Fig. 4 is a section on line 4–4 of Fig. 2, Fig. 4a is a section on line 4a–4a of Fig. 2, Fig. 5 is a fragmentary plan view of the stock body with the cutters and clamp omitted, Fig. 6 is a bottom plan view of Fig. 5, and Fig. 7 shows the clamp in plan and in rear elevation.

Referring to the drawing, the stock or body 10 is formed of a flat metal plate having a knob or handle 11 projecting upward from the rear end. In advance of the knob 11 the body is provided with a raised portion or enlargement 12 having intersecting grooves 13, 14. The groove 13 is deeper than the groove 14 and said grooves lead completely to the forward edge of the stock at the corners thereof, as shown at 13a and 14a respectively in Fig. 5. Secured to the forward edge of the stock or body at the median portion thereof is a transverse nose piece 15 having an extension 16 opposing the open end 13a of the groove 13 and forming in connection therewith a throat 17 into which projects the forward cutting end of a cutter 18 located in the groove 13. At the opposite end of the nose piece 15 the same is provided with an extension 19 forming in connection with the forward extremity 14a of the groove 14, a throat 20 directed transversely of the plane in line with the throat 17 but at the opposite side of the plane, which throat 20 receives the cutting edge of a cutter 21. This cutter 21 is located in the groove 14 and its rear portion passes over and across the rear portion of the cutter 18. Both cutters 18 and 21 fit snugly in the corresponding grooves 13 and 14, and while the axes of the cutters are directed at an angle to a line extending transversely of the plane, the forward cutting edges of said cutters are substantially parallel to such a line as shown in Fig. 2.

Both cutters are clamped in position in the stock by the same clamping means. In the form shown, I employ a clamp 21a secured to the stock or bed plate 10 by a clamping screw 22. By preference, the screw 22 engages a threaded socket 23 tapped in the stock or bed plate at a point slightly in front of the intersection of the grooves 13, 14. The clamp 21a is formed of a metal plate extending transversely of the plane and having downturned extremities 24. One of these extremities 24 is adapted to rest upon the cutter 18 at a point slightly in the rear of the cutting edge, and the other downturned extremity 24 of the clamp is adapted to engage the cutter 21 in a similar location so that as the clamp screw 22 is screwed into its socket 23, the clamp will be forcibly brought down on both cutters so as to hold them securely in position.

In using the plane, the cutter 18 will be employed for cutting when the plane is moved in one direction, and when it is desired to reverse the plane and move it in the opposite direction, it is simply necessary to turn it around and use the cutter 21. Hence no adjustment of the cutters is necessary in reversing the plane.

In planing in corners or similar locations, the nose piece 15 may be entirely removed if desired, and this may be effected by removing a single screw 25 which passes through said nose piece into the forward edge of the bed plate. This single screw will hold the nose piece securely on the end of the bed plate in connection with a tongue and groove joint 26 formed at the meeting surfaces of the nose piece and bed plate, as shown in Figs. 1 and 4.

Without limiting myself to the construction shown, I claim:

1. In a plane, a bed plate or stock having transversely arranged throats at the opposite forward corners thereof, there being grooves in said bed plate extending rearwardly from said throats and intersecting each other, cutters adapted to fit said grooves, clamping means for said cutters located in front of the intersection of said grooves; and a knob fixed on said bed plate at the rear of such intersection; substantially as described.

2. In a plane, a bed plate having intersecting grooves, one of said grooves being deeper than the other at the point where said grooves intersect, cutters located in said grooves and overlapping each other, and a single means for clamping both cutters in said grooves; substantially as described.

3. In a plane, a bed plate having cutter-receiving grooves extending to one edge thereof, and a detachable nose piece applied to said edge of the bed plate and forming in connection with the ends of said grooves, throats for the cutting ends of the cutters; substantially as described.

4. In a plane, the combination of a bed plate or stock having transversely arranged throats at the opposite forward corners thereof, there being grooves in said bed plate extending rearwardly from said throats, cutters fitting said grooves, a single clamp to secure both of said cutters in the respective grooves at the same time, and a knob fixed to the bed plate at the rear of the cutters; substantially as described.

5. In a plane, the combination of a bed plate or stock, having intersecting cutter-receiving grooves terminating at the forward corners thereof, one of said grooves being deeper than the other at the point of intersection, cutters fitting the respective grooves, a single clamp for securing the cutters in the respective grooves, in overlapping relation, and a single detachable nose piece cooperating with the forward ends of both grooves to form throats for the cutters; substantially as described.

6. In a plane, a bed plate having cutter-receiving grooves on the upper surface thereof extending to one edge of the bed plate, a nose piece detachably secured to said edge of the bed plate between said grooves, and extensions on said nose piece located in front of the groove ends; substantially as described.

7. In a plane, the combination of a substantially flat bed plate, cutters projecting beyond the front edge of said bed plate at different points, means to secure said cutters on said bed plate, and a nose piece detachably secured to the front edge of the bed plate between said cutters and forming, in conjunction with the bed plate, throats for both cutters; substantially as described.

8. In a plane, the combination of a stock, crossed overlapping cutters having their cutting edges arranged at the respective forward corners of the stock, a single clamp for clamping both cutters on the stock at the same time, and a knob hired to the rear portion of the stock; substantially as described.

In witness whereof, I have hereunto set my hand on the 9th day of July 1913.

WILLIAM E. SPARKS.

Witnesses:

JOHN H. SHAW,

BERTHA RAY.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents, Washington, D. C.”

_________________