No. 325,571 – Spokeshave (Charles William Smith) (1885)

UNITED STATES PATENT OFFICE.

_________________

CHARLES WILLIAM SMITH, OF WESTERLY, RHODE ISLAND.

SPOKESHAVE.

_________________

SPECIFICATION forming part of Letters Patent No. 325,571, dated September 1, 1885.

Application filed June 27, 1885. (No model.)

_________________

To all whom it may concern:

Be it known that I, C. W. SMITH, a citizen of the United States, residing at Westerly in the county of Washington and State of Rhode Island, have invented certain new and useful Improvements in Tool-Holders; and I do declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it appertains to make and use the same, reference being had to the accompanying drawings, and to letters or figures of reference marked thereon, which form a part of this specification.

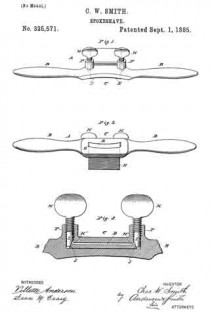

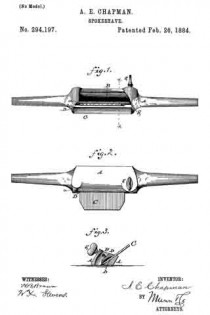

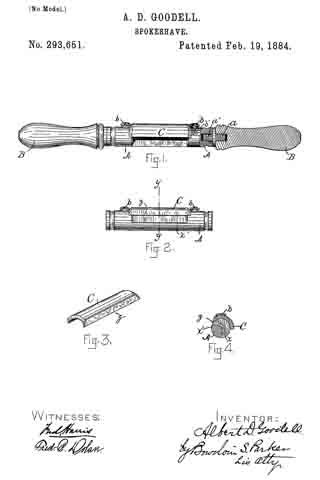

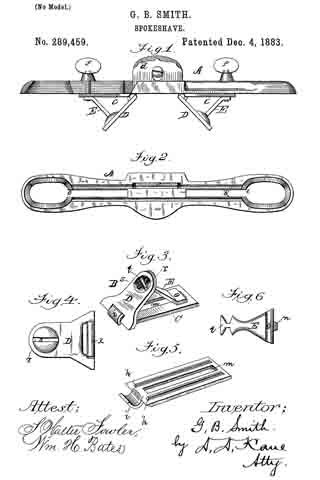

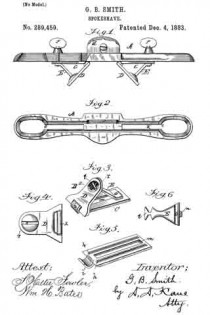

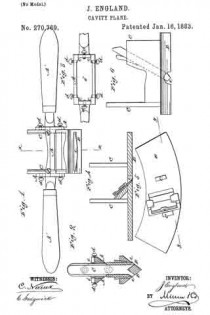

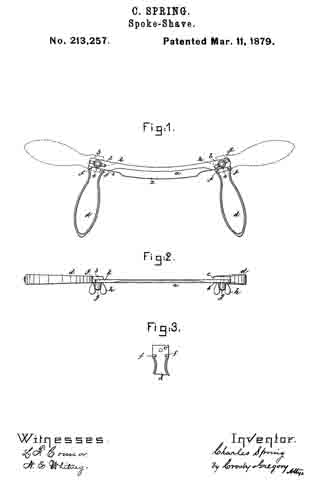

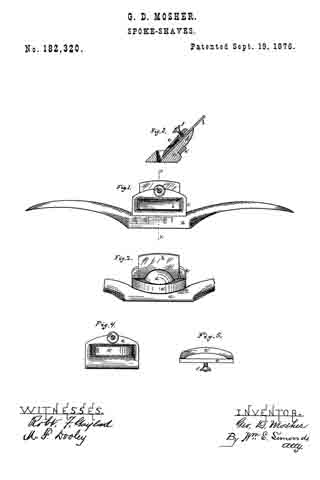

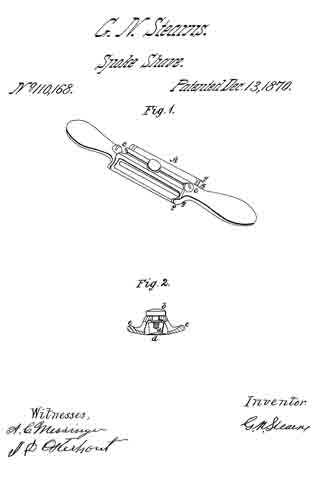

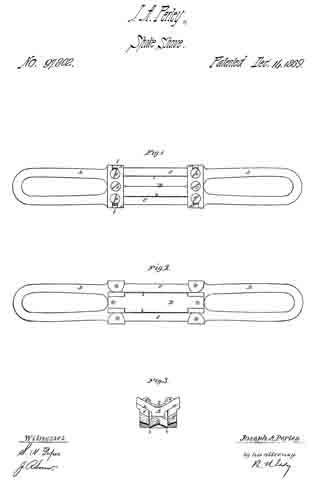

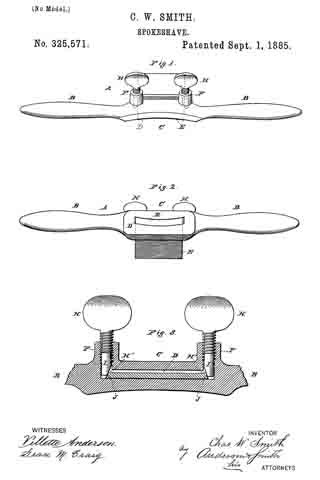

Figure 1 of the drawings is a representation of this invention, and is a front view. Fig. 2 is a view of the under side. Fig. 3 is a longitudinal section taken in line with the set-screws and studs when held vertically.

This invention relates to tool-holders of the class commonly termed “spokeshaves;” and it consists in the construction and novel arrangement of devices, all as hereinafter fully described, and particularly pointed out in the claim.

Referring by letter to the accompanying drawings, A designates the tool-handle, having the usual arms, B B. The middle portion, G, of the tool-holder is provided with a throat, D, for the tool or blade E. At each end of the throat D is provided a hollow stud, F, Which communicates at its lower end with the throat D, and is threaded internally in its upper end for the reception of a set-screw, H, a screw, H, being employed in each hollow stud F. The lower portion of each hollow stud is provided with an opening, H’, which conununicates with the throat D of the tool-holder.

In the bottom of each stud F is placed a key, I, the upper end of which is cylindrical in cross section. The keys I I are beveled at one side to cause them, when in proper position in their seats, to bear against the edges of the bits J when the screws H H are turned down upon them to hold the bit K in place in the throat D of the tool-holder, and in the position to which the latter may have been adjusted.

To adjust the bit K the set-screws must be loosened, the bit moved, and the set-screws H H must be again tightened.

This construction is simple, and the parts are positive in their action.

Having thus fully described my invention, what I claim as new, and desire to secure by Letters Patent of the United States, is —

The combination, with the tool-handle having the throat and the hollow studs having threaded upper portions, and the open lower portions communicating with the throat of tool-handle, of the keys I I, provided with longitudinally-beveled faces, and the set-screws for operating the keys to engage the lateral edges of the cutter, substantially as specified.

In testimony whereof I attire my signature in presence of two witnesses.

CHARLES WILLIAM SMITH. [L. S.]

Witnesses:

JOS. W. BRYANT,

WM. H. BRYANT.