No. 306,763 – Plane (Stephen G. Laskey) (1884)

UNITED STATES PATENT OFFICE.

_________________

STEPHEN G. LASKEY, OF CHELSEA, MASSACHUSETTS.

PLANE.

_________________

SPECIFICATION forming part of Letters Patent No. 306,763, dated October 21, 1884.

Application filed February 7, 1884. (No model.)

_________________

To all whom it may concern:

Be it known that I, STEPHEN G. LASKEY, of Chelsea, in the county of Suffolk, State of Massachusetts, have invented a certain new and useful Improvement in Planes, of which the following is a description sufficiently full, clear, and exact to enable any person skilled in the art or science to which said invention appertains to make and use the same, reference being had to the accompanying drawings, forming a part of this specification, in which —

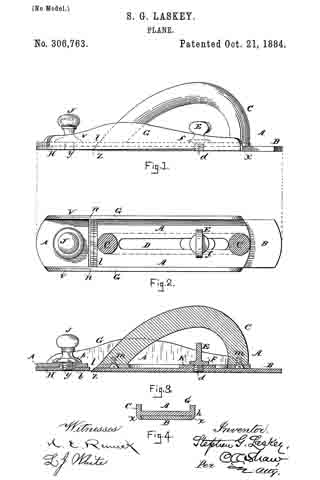

Figure 1 is a side elevation of my improved plane; Fig. 2, a top plan view with the handle removed; Fig. 3, a vertical longitudinal section, and Fig. 4: a vertical transverse section of the body and iron.

Like letters of reference indicate corresponding parts in the different figures of the drawings.

My invention relates more especially to the class of planes known as “block” planes; and it consists in a novel construction and arrangement of the parts, as hereinafter more fully set forth and claimed, by which a simpler, cheaper, lighter, and more effective device of this character is produced than is new in ordinary use.

The nature and operation of the improvement will be readily understood by all conversant with such matters from the following explanation, its extreme simplicity rendering an elaborate description unnecessary.

In the drawings, A represents the body, B the iron, and C the handle. The body is preferably composed of metal, and is provided with a dovetail channel, h, extending longitudinally along its under side to receive the iron, which is correspondingly beveled at the edges to fit the channel. The handle is preferably evolute in form, and is secured to the upper side of the body by the screws m, as shown in Fig. 3. The body is provided on either side with a vertical flange, G, and at its center with an elongated slot, D, extending lengthwise thereof between the ends of the handle, and fitted to work therein is a thumb-screw, E, having a wide annular flange, f, the screw entering a threaded hole, d, in a hub, K, on the iron, the hub projecting upwardly into the slot. A transverse slot, l, is cut through the body A. between the flanges G, the rear wall of this slot being inclined toward the handle C, the incline corresponding nearly with the incline of the cutting or beveled end z of the iron B. A shoe, H, having an upwardly-extending flange, v, on either side, is attached to the forward end of the plane, the flanges working in rabbets n, formed in the flanges G, and the face or lower side of the shoe being flush with the lower edges of the last-named flanges, which are cut away forward of the throat l to form ways for the shoe. A thumb-screw, J, provided with an annular flange, p, is fitted to work in a hole in the forward end of the body A, the screw entering a correspondingly-threaded hole, y, in a hub, b, on the shoe H, and the flange resting on the upper side of the body above the shoe. The lower edges of the flanges G are slightly rounded or beveled, as shown at x in Fig. 4, to prevent them from resting with their entire surface on the wood or article being planed.

In the use of my improvement the iron B is inserted in the channel h in the body A., with the bevel of its cutting end z uppermost, and, after being properly adjusted with respect to the throat l, is secured in position by turning in the screw E and bringing the flange f into forcible contact with the upper side of the body. The shoe H is then raised or lowered, as the case may be, by turning the screw J to the right or left until the lower side or face of the shoe is elevated above the lower side or face of the iron B a distance corresponding with the kerf or thickness of the shaving it is desired to cut, the plane being then ready for use.

I am aware that it is not new, broadly, to construct a plane in which the plane-iron constitutes a part of the bottom of the stock, said plane-iron being driven tightly into dove-tail grooves in said stock.

I am also aware that it is not new to construct a plane with a plane-iron arranged flat-wise in a recess in the under side of the stock extending backward a short distance from the throat, the rear end of said plane-iron being flush with the bearing-surface of the stock and the front end thereof adjustable vertically.

I am also aware that adjustable shoes are not new, broadly.

Having thus explained my invention, what I claim is —

1. The combination of a stock provided with a transverse throat, a dovetailed recess on its under side, and a longitudinal slot in rear of the throat, a plane-iron adapted to fit said recess, provided with a boss projecting into said slot, and having a threaded socket and a thumb-screw which enters said socket, and has a flange which projects over the side of the slot, substantially as described.

2. The combination of a stock provided with rabbets in its side checks and with at slot in its bottom in front of the throat, an adjustable shoe provided with upwardly-projecting flanges adapted to slide in said rabbets, and with a socket projecting upward into said slot, and a set-screw for adjusting said shoe, substantially as described.

STEPHEN G. LASKEY.

Witnesses:

C. A. SHAW,

L. J. WHITE.