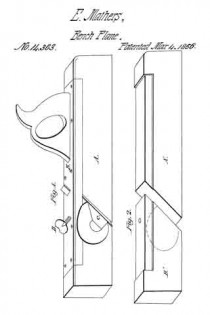

No. 14,363 – Bench Plane (Ebenezer Mathers) (1856)

UNITED STATES PATENT OFFICE.

_________________

EBENEZER MATHERS, OF MORGANTOWN, VIRGINIA.

BENCH-PLANE.

_________________

Specification of Letters Patent No. 14,363, dated March 4, 1856.

_________________

To all whom it may concern:

Be it known that I, EBENEZER MATHERS, of the town of Morgantown, county of Monongalia, State of Virginia, have invented a new and useful Improvement in Bench-Planes; and I do hereby declare that the following is a full, clear, and exact description of the construction and operation of the same, reference being had to the accompanying drawings, making a part of this specification, with letters of reference marked thereon.

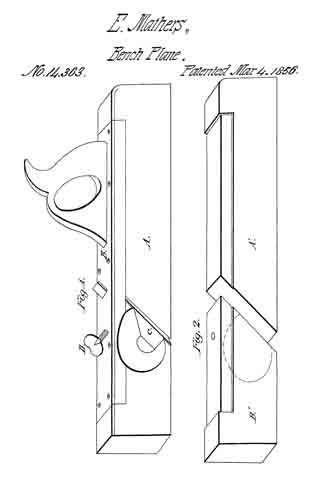

A, Figure 1, stock of the plane. B, Fig. 1, metal cap, flanged on each side, fitted flush on to the blocks A’, and B’, Fig. 2. C the bit, which is wide as the stock. Above is seen the end of the tang projecting from the bit, up through an opening in the cap made to receive it. D, Fig. 1, set screw for tightening the bit. The throat opens on the left side of the plane. Fig. 2 is a view of the blocks with the cap off, showing the slope of the cut dividing them, also the recess to receive the cap. The dotted line shows where the throat is cut out.

The advantages of this plane are, first, it is not liable to choke as there is nothing to obstruct the shavings; second, the bit may be as wide as the stock, which cannot be the case in the old form of planes. Another advantage is the great facility with which the bit can be adjusted or removed. Lastly, the blocks composing the stock can be removed when worn out and new ones substituted.

This is particularly the case with the front block which always wears out first.

What I claim as new and desire to secure by Letters Patent is —

The construction of bench planes with the stock in two pieces connected by a metal, cap, as above set forth substantially.

EBENEZER MATHERS.

Witnesses:

JOSEPH K. MATHERS,

JOHN H. SNIDER.