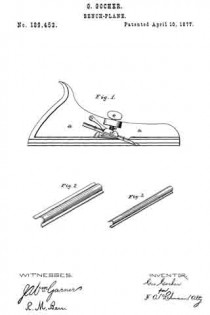

No. 189,453 – Improvement In Bench-Planes (George Gocher) (1877)

UNITED STATES PATENT OFFICE.

_________________

GEORGE GOCHER, OF JOHNSTOWN, PENNSYLVANIA.

IMPROVEMENT IN BENCH-PLANES.

_________________

Specification forming part of Letters Patent No. 189,453, dated April 10, 1877; application filed January 24, 1877.

_________________

To all whom it may concern:

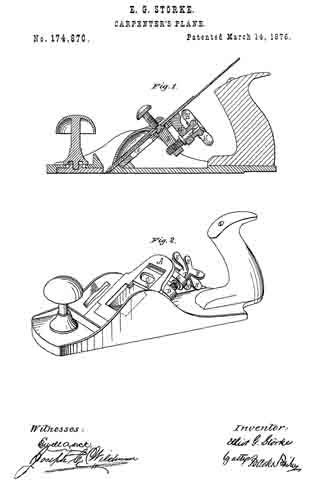

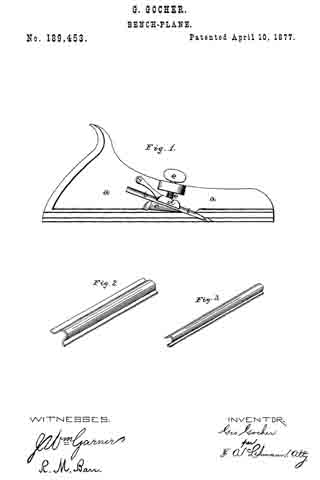

Be it known that I, GEORGE GOCHER, of Johnstown, in the county of Cambria, and State of Pennsylvania, have invented certain new and useful Improvements in Bead-Planes; and Ido hereby declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it pertains to make and use it, reference being had to the accompanying drawings, which form part of this specification.

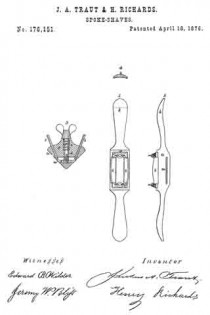

My invention relates to an improvement in bead-planes; and it consists in a bit which has a bead running its entire length, and the devices by which the bit is secured to the stock, all of which will be more fully described hereinafter.

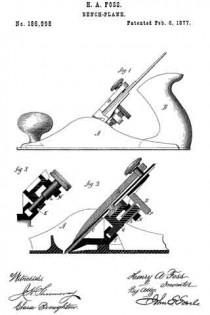

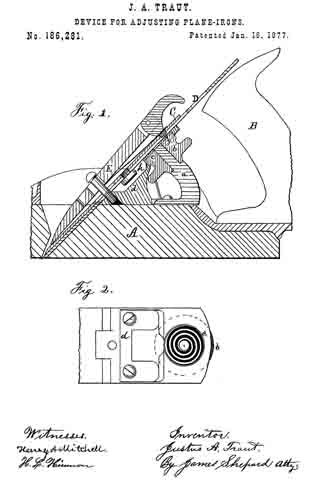

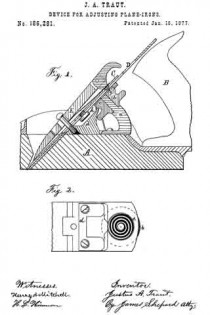

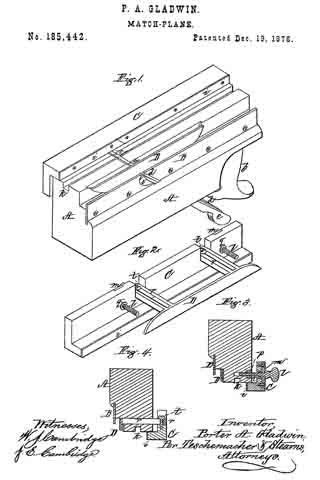

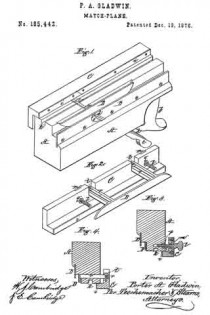

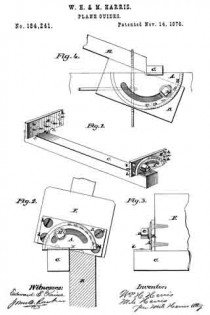

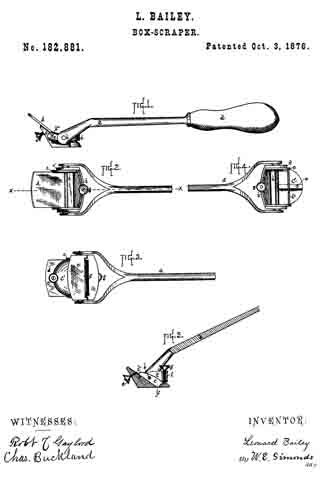

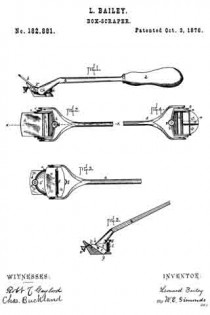

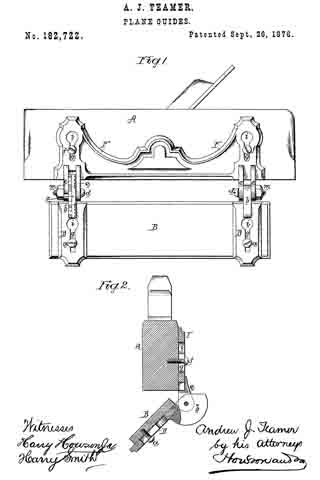

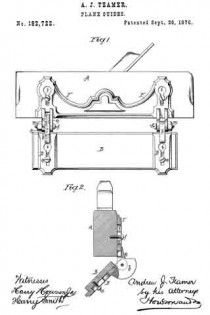

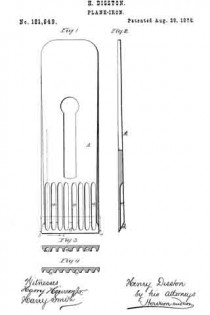

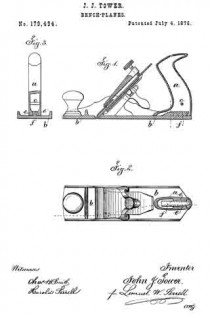

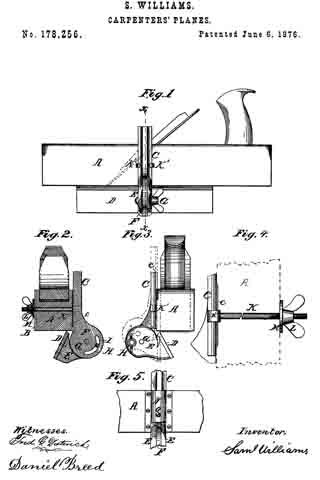

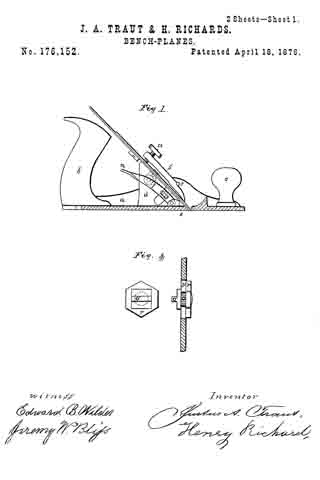

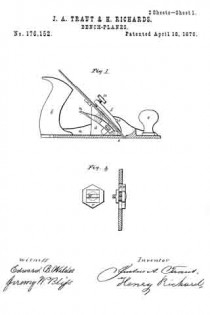

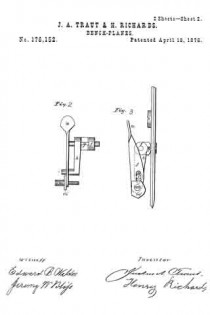

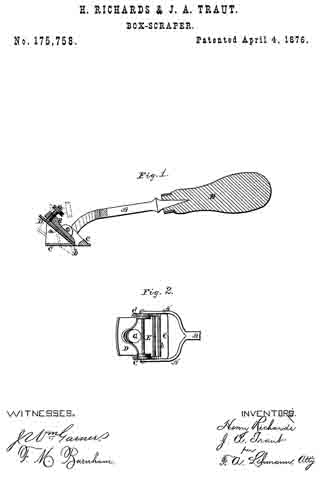

The accompanying drawings represent my invention. a represents the stock, which may be of the form here shown, or any other that may be preferred, and which has its lower edge so formed as to cut beads, or any other form of surface that may be preferred. Just in the rear of the opening through the lower edge of the stock, through which the end of the bit passes, is formed the inclined plane c, the top edge of which is shaped so as to fit the under side of the bit which rests upon it. Pivoted to the side of the stock is a clamp, d, which is pressed down upon the top of the bit by means of a set-screw, e. thereby serving to hold the bit in any position in which it may be clamped.

The bit i is made of a thin sheet of steel of even temper throughout, rolled or otherwise formed so as to correspond to the bead or other form of work required. As the groove is made in the under side of the bit its entire length, as soon as it becomes dull it is only necessary to remove it and sharpen it as they would any other tool, without the trouble of drawing its temper or having to form the groove, whereby a great deal of time and trouble is saved. By thus forming the bit, not only for this but other kinds of work, they can be made much more cheaply and can be used their entire length.

I am aware that a cutter-head for planing-machines, having circular beveled cutting edge, is not new, and this I disclaim. My invention is confined to bits for planes alone. and whereby the bit can he readily and easily sharpened and used its entire length as it wears away.

Having thus described my invention, I claim —

The combination of a bit, i, made from a single sheet of metal, and having a bead rolled its entire length, with the stock a, having the inclines c and clamp d, and a set-screw, e, substantially as specified.

In testimony that I claim the foregoing I have hereunto set my hand this 17th day of January, 1877.

GEORGE GOCHER.

Witnesses:

T. F. LEIGH,

THOMAS PENDRY.