| PLEASE NOTE: The images presented on this page are of low resolution and, as a result, will not print out very well. If you wish to have higher resolution files then you may purchase them for only $2.95 per patent by using the "Buy Now" button below. All purchases are via PayPal. These files have all been cleaned up and digitally enhanced and are therefore suitable for printing, publication or framing. Each zip package contains all the images below (some packages may contain more), and purchased files can be downloaded immediately. |

UNITED STATES PATENT OFFICE.

_________________

JUSTUS A. TRAUT, OF NEW BRITAIN, CONNECTICUT.

SPOKESHAVE.

_________________

SPECIFICATION forming part of Letters Patent No. 668,299, dated February 19, 1901.

Application filed October 29, 1900. Serial No. 34,012. (No model.)

_________________

To all whom it may concern:

Be it known that I, JUSTUS A. TRAUT, a citizen of the United States, residing in New Britain, in the county of Hartford and State of Connecticut, have invented certain new and useful Improvements in Spokeshaves, of which the following is a specification.

This invention relates to spokeshaves, and has for one object the provision of an improved tool which may be employed on various varieties of wood with good results and one in which the knife and the guard or throat-gage are adjustable in planes at right angles to each other; the back of the guard being formed with a plane face constituting a wall of the throat for the reception of the shavings, whereby the straight edge of said guard opposed to the knife may when injured or blunted be readily renewed by simply grinding said face.

A further object of the invention is the provision within the stock of the spokeshave of a chamber for the reception of shavings, the upper wall of said chamber being curved outwardly to facilitate the discharge of said shavings.

A further object of the invention is the provision, in connection with a spokeshave, of a guard or throat-gage, the working surface of which is convex both transversely and longitudinally.

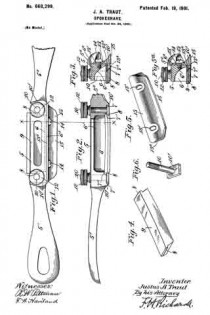

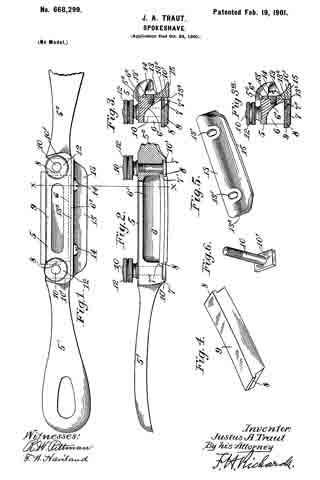

In the accompanying drawings, Figure 1 is a plan view of my improved spokeshave, part of one of the handles being broken away. Fig. 2 is a side elevation, partially in section. Figs. 3 and 3a are transverse sections on line into of Figs. 1 and 2, showing different adjustments of the guard or throat-gage. Fig. 4 is a perspective view of the knife or cutter. Fig. 5 is a perspective view of the guard, and Fig. 6 is a perspective view of one of the bolts for adjustably securing the knife in position.

Similar characters designate corresponding parts throughout the several views.

Referring to the drawings, the numeral 5 designates the stock of my improved spoke-shave, having the usual handles 5′ 52 and provided with a chamber 6 (the wall 6′ of which is curved outward for a purpose hereinafter described) and with a forward straight portion 62.

Formed in the stock at each end of the chamber 6 are grooves 7, having rabbeted portions 7′, constituting guideways for the reception of flanges 8 on the ends of a knife or cutter 9, which is preferably of the “razor-blade” type and is slightly curved longitudinally, and fitted in said grooves 7 are the flat oblong heads 10′ of bolts 10, the threaded shanks of which pass through perforations in the stock and carry thumb-nuts 12, by turning which the heads 10′ may either be forced tightly against the flanges 8 of the cutter or released therefrom to permit said cutter to be adjusted, as desired. Cooperating with this cutter is a guard or throat-gage 13, slotted at 13′ for the reception of screws 14, which enter the stock, in virtue of which construction the guard may be adjusted transversely of the cutter to vary the dimensions of the throat in which the shavings enter between said parts.

It will be observed by reference to Figs. 3 and 3a that this guard is provided with a plane back 132, which terminates in a straight edge 133, and when this straight edge is blunted or otherwise injured by wear, as frequently happens, it can readily be restored by removing the guard and grinding the flat face 132, after which it can be replaced with said face in engagement with the corresponding flat face 62 of the stock. On its lower or grinding surface the guard is made convex both longitudinally and transversely, as at 15, and can therefore much more readily be applied to rounded surfaces of the work. The face 15, which extends outward from the edge 133, is joined to the back 132 by the curved surface, which at its upper portion becomes nearly or quite parallel to the back, forming a body of convenient thickness in which to locate the slots 13′.

By reference to Figs. 3 and 3a it will be seen that the knife 9 and guard 13 may be so adjusted with relation to each other that the cutting edge of the knife will be brought into line with and almost touch the straight edge of the guard, whereby a very fine shaving may be removed from the work, if desired.

This is especially important when cutting hard wood or across the grain and obviates to a large extent the danger of splitting the wood or of tearing out a splinter therefrom — accidents of frequent occurrence with the old styles of spokeshaves, in which the knife overlaps a beveled edge on the guard.

As is well known, chips or shavings entering the mouth between the guard and knife tend to curl or assume a helical form, and to aid them in this action they are caused to impinge against the curved wall 6’ of the chamber 6 and are by said wall guided and defiected toward the exterior of the stock.

By my improved construction it will be seen that the guard may be so adjusted that the edge of the knife may be brought into line with the straight edge 133 or caused slightly to overlap the same, if desired, thereby enabling the tool to be employed on various kinds of woods, either hard or soft, at pleasure, for, as is obvious, the height of the knife above the guide-surface and also the position of the cutting edge may be regulated with nicety to obtain a throat of the desired width.

As will be observed, the flat oblong heads 10′ of the bolts 10 extend equally on each side of said bolts, and as said heads snugly fill the grooves 7 of the stock the bolts are thus interchangeable and reversible, so that the parts may be disassembled and reassembled regardless of their original positions. Furthermore, the top surfaces of the heads of these bolts and the bearing-surface of the guard or throat-gage are flush with each other, so as to form a smooth working face for the tool.

Preferably the stock and its handles are formed of metal in an integral casting, although the invention is not limited in this respect.

My invention is not limited to the precise details illustrated and described, and modifications may be made in the shape of the parts without departure therefrom.

Having thus described my invention, what I claim is —

1. In a spokeshave, the combination with a chambered stock of a cutter secured in said stock; and a guard or throat-gage cooperating with said cutter and having a working face curved in two directions and a plane back adjacent to the curved surface, said guard being adjustable to bring the working surface of said gage substantially to a position in line with the edge of the cutter.

2. In a spokeshave, the combination, with a stock and its handles, said stock having a chamber with an outwardly-curved wall and also having grooves and guideways at the ends of said chamber, of a longitudinally-curved cutter having flanges fitted in the ways of said stock; bolts having heads in engagement with said flanges; a guard or throat-gage having a straight back portion adjustably secured to the forward wall of the stock, the working surface of said guard or throat-gage projecting from said back portion and being curved both longitudinally and transversely, and said gage being adjustable on the stock to bring its working surface substantially into line with the edge of the cutter, substantially as and for the purpose specified.

JUSTUS A. TRAUT.

Witnesses:

ROBT. N. PECK,

M. G. PORTER.