| PLEASE NOTE: The images presented on this page are of low resolution and, as a result, will not print out very well. If you wish to have higher resolution files then you may purchase them for only $2.95 per patent by using the "Buy Now" button below. All purchases are via PayPal. These files have all been cleaned up and digitally enhanced and are therefore suitable for printing, publication or framing. Each zip package contains all the images below (some packages may contain more), and purchased files can be downloaded immediately. |

UNITED STATES PATENT OFFICE.

_________________

NOAH N. BEASLEY, OF GREELEY, COLORADO.

GAGE ATTACHMENT FOR PLANES.

_________________

857,514. Specification of Letters Patent. Patented June. 18, 1907.

Application filed June 11, 1906. Serial No. 321,119.

_________________

To all whom it may concern:

Be it known that I, NOAH N. BEASLEY, a citizen of the United States, residing at Greeley, in the county of Weld and State of Colorado, have invented certain new and useful Improvements in Gage Attachments for Planes; and I do declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it appertains to make and use the same, reference being had to the accompanying drawings, and to the letters and figures of reference marked thereon, which form a part of this specification.

My invention relates to an attachment for planes consisting of a sort of gage attached to the plane and adjustable in such a manner that when the gage plate engages the flat-side of the board or piece of wood whose edge is to be acted on by the plane, the said edge may be cut down to form a horizontal surface or a surface inclined to the horizontal, according to the position of the gage plate.

An important feature of my invention consists in the means whereby the gage plate is apljusted and locked in the desired position of adjustment.

Having brieliy outlined my improved construction as well as the function it is intended to perform, I will proceed to describe the same in detail reference being made to the accompanying drawing in which is illustrated an embodiment thereof.

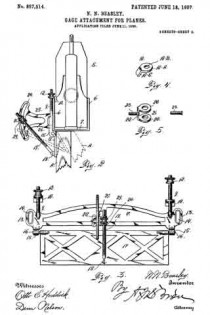

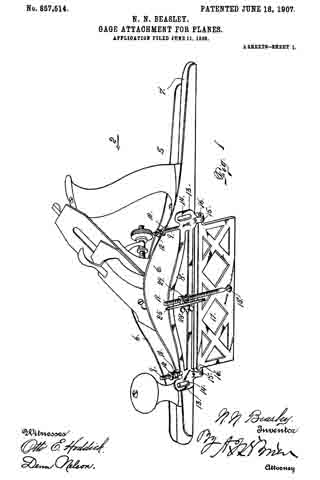

In this drawing, Figure 1 is a perspective view of a metal plane equipped with my improved attachment. Fig. 2 is a front end elevation of the construction shown in Fig. 1 or a view looking in the direction of the arrow in said figure. Fig. 3 is a detail view of my improved gage shown on a larger scale. Figs. 4 and 5 are perspective views in detail of features used in connection with the device, the same being shown on a larger scale.

The same reference characters indicate the same parts in all the views.

Let the numeral 5 designate the body of the plane which in this particular instance is provided with parallel sides 6 extending upwardly from the bottom plate 7. To one of these sides 6 my device is attached and will now be described in detail.

Let the numeral 8 designate the body part of the device or the part which is relatively stationary when fixedly attached to the plane. This body part as shown in the drawing consists of an integral plate cut away in part to diminish the weight and amount of material employed. The opposite extremities of this body part are provided with upwardly projecting screws 9 upon which are loosely mounted angle clips or keepers 10. The member 10A of each of these clips is provided with a plain or unthreaded opening 10B adapted to slide freely on the screw. Above each angle clip of each screw 9 is located a thumb nut 12.

When the device is in use the angle clips 10 are adjusted to engage the upper edge of one of the side plates 6 of the plane, the thumb nuts are screwed down to hold the same in place. In this case the depending member 10C of the clip engages the inside surface of the plart 6 of the plane. Adjacent each screw 9, the plate 8 is provided with an ear 13 having a vertically-disposed elongated opening 14 through which screws or other suitable devices may be passed, when it is desired to attach the gage to a wooden plane.

Extending below each extremity of the plate 8 and formed integral therewith is an apertured lug 15 adapted to receive a bearing pin or journal 16 which is passed through the opening in the lug and secured to the gage plate 17 . One of these pins may if desired be formed integral with the gage plate while the other may be passed through the lug and threaded into an opening therefor. It is also evident that any other suitable construction of bearing 15 may be employed. Regardless of the details of construction, the gage plate 17 is pivotally connected with the relatively stationary body part 8. A screw stem 19 is hinged at its lower extremity as shown at 18, to the lower part of the plate 17. This screw stem passes through the apertured parallel parts 20 of a U-shaped keeper 21 whose member 22 connecting the two arms is also apertured to receive a screw 23 which passes through the curved slot 24 of a segmental arm 25 made fast to the body plate 8 of the gage. The inwardly-extending part 26 of the segment is centrally connected with the plate 8 and between this connection and the slotted part is formed an offset 27 to make room for the keeper 21 and the screw stem 19 whereby the screw stem may occupy a central position with reference to the parts 8 and 17 ofthe gage. On the opposite side of the slotted segment from the keeper, a thumb nut 28 is applied to the screw 23.

The shank of the screw adjacent the head or where it passes through the keeper, should be formed square or angular in cross section to fit a counterpart opening in the keeper, to prevent the screw from turning while tightening the thumb nut.

Mounted on the screw stem 19 and occupying a position between the arms 20 of the keeper, is a thumb nut 29 which is employed to adjust the position of the gage plate, whereby the latter may be thrown to any desired angle to the plane of the body part 8.

ln the use of the device the gage plate 7 may be adjusted to occupy the desired angle approximately with the plane 8. Then by turning the thumb nut 29, an accurate or close adjustment may be easily obtained.

From the foregoing description the use and operation of my improved device will be readily understood. Having attached the device to the plane as shown in Fig. 1, and after adjusting the gage plate 17 to the desired position or angle with reference to the body part 8 of the device, the planing operation is commenced and continued until, with the base plate 7 of the plane engaging the edge of the board, the gage plate 17 engages one of the flat surfaces thereof at an angle to the horizontal. In this way if the edge of the board is inclined with reference to one of its flat sides, it may be planed gradually to the horizontal; or if it is already horizontal and it is desired to bevel it or give it any desired incline, this may be effected in the same manner.

In Fig. 2 of the drawing the dotted line position of the board A shows the same inclined to the vertical and with its edge planed to form oblique angles with the planes of its side walls, the dotted line position of the screw stem 19, the thumb nut 29 and the keeper 21, corresponding with the dotted line position of the board A. It will be readily understood, however, that by maintaining the board A in the vertical position, any desired bevel may be formed upon its edge, simply by properly adjusting the gage plate 17, and then planing the edge to the desired bevel, but in this case it will be necessary for the operator to hold the plane in an inclined position. It is believed that this latter method of procedure will be followed though it is of course practicable to use the device in either way , but it is evident that it will be more easy to hold the door A in a vertical than an inclined position on the ordinary work bench.

Having thus described my invention, what I claim is:

1. A gage attachment for planes, consisting of a body art adapted to be fixedly connected with the plane, a gage plate pivotally connected with the body part and adapted to be adjusted in either direction to any required angle, a screw stem hinged to the gage plate, a U-shaped keeper through whose parallel arm the screw stem passes, a screw connected with the keeper, a slotted segmental member connected with the body of the device, the screw of the keeper passing through the slot of the segment, and a thumb nut applied to the screw stem connected with the gage plate, and occupying a position between the parallel arms of the keeper.

2. A gage plate attachment for planes, consisting of a body art, a gage plate pivotally connected witii the body part and adapted to be adjusted in either direction to any required angle, a slotted segment also connected with the body art, a screw stem pivotally connected with iihe gage plate, and a suitable connection between the screw stem and the slotted segment for regulating the position of the gage plate with reference to the body of the device, and suitable means connected with the threaded stem for adjusting the gage plate independently of the adjustment permitted by the slotted segment.

3. In a device of the class described, the combination with a body part consisting of a plate whose extremities are provided with suitable means for fixedly connecting the body part with a plane, a gage plate pivotally connected with the body part and adapted to be adjusted in either direction to any required angle, the body part being provided with a member having a curved slot, a stem hinged to the gage plate, a suitable connection between the stem and the part having the curved slot, to permit the adjustment of the gage plate, and suitable means connected with the stem for adjusting the position of the gage plate independently of the adjustment permitted by the slotted part.

4. A gage attachment for planes, consisting of a body part provided with upwardly projecting screws, angle clips slidable on the screws and adapted to engage the upper edge of a metal plane, nuts applied to the screws above the angle clips, the extremities of the body part being provided with depending ears, a gage plate adapted to be adjusted in either direction to any required angle and provided with pins at its extremities journaled in the ears of the body part, a threaded stem hinged to the body part, a U-shaped keeper whose parallel arms are provided with unthreaded openings through which the threaded stem asses, a nut engaging the threaded stem and occupying a position between the said keeper arms, a screw connected with the keeper, a slotted segment through which the keeper screw passes, and a thumb nut applied to the keeper screw for locking the keeper in any desired position on the segment.

In testimony whereof I affix my signature in presence of two witnesses.

NOAH. N. BEASLEY.

Witnesses:

G. E. M. HOUSTON,

J. H. GAMBREL.